Novel architecture gypsum powder and its preparation method

A kind of construction gypsum powder, a new type of technology, applied in the field of new construction gypsum powder, can solve the problems of poor fluidity, long setting time, narrow particle distribution band, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

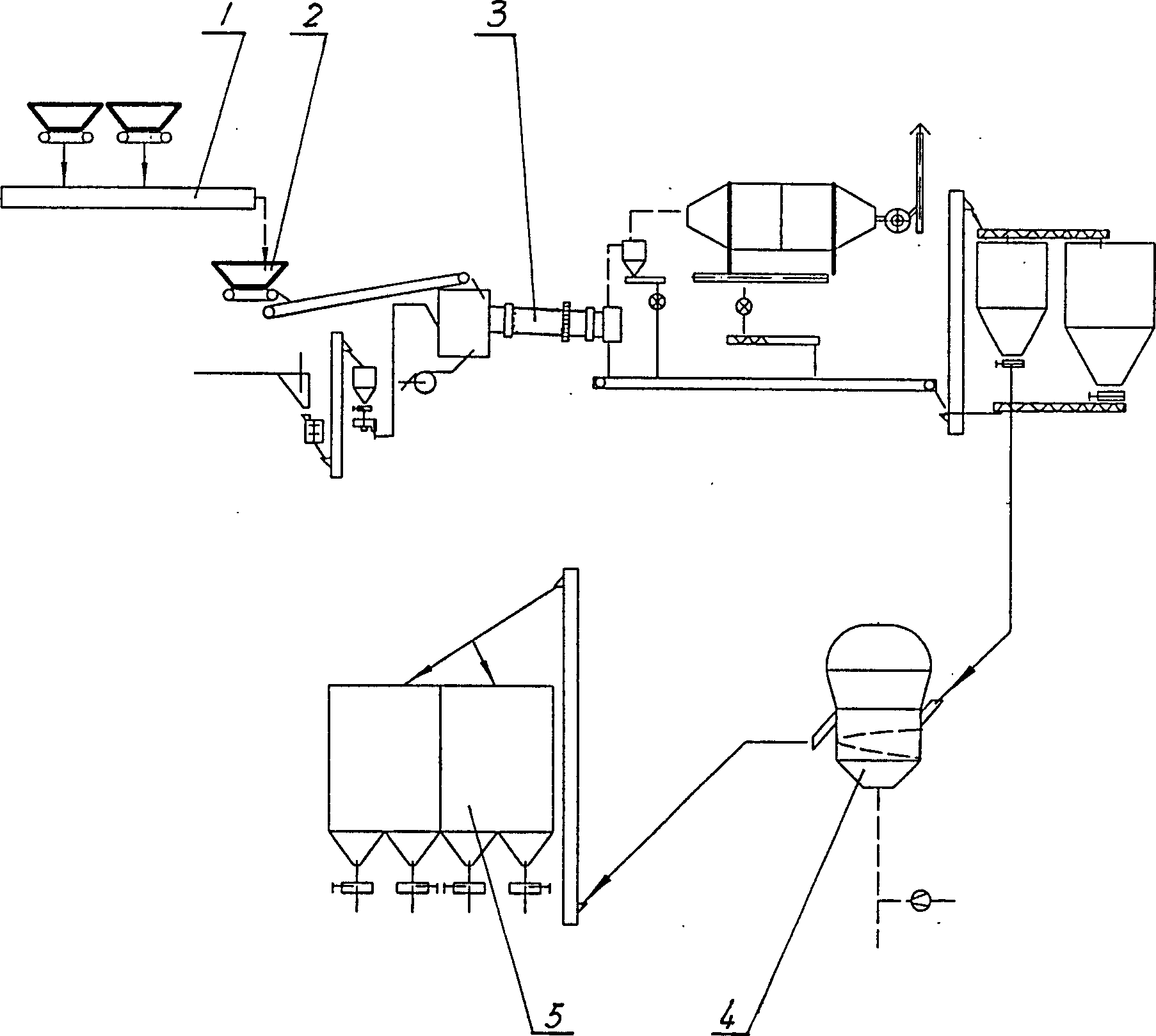

[0007] Phosphogypsum is generally industrial waste from phosphate fertilizer production, and its free water moisture content is generally 8-25%; desulfurized gypsum is generally industrial waste after desulfurization treatment in coal-fired power plants, and its free water moisture content is generally 8-12%. Prepare phosphogypsum and desulfurized gypsum according to their weight ratio: phosphogypsum: desulfurized gypsum=50~90%:10~50%, and send it to the mixer (2) through the conveying device (1) for mixing and mixing, and then send it to the mixer (2). Drying is carried out in the drum dryer (3), and the drying temperature is controlled at 80-150℃ to remove the free moisture in the mixture, so that the free moisture in the dried mixture is controlled at 0-5%; The dried mixture is sent to the boiling furnace (4) for calcination. The calcination temperature is controlled at 160~200℃. The calcination adopts continuous calcination to remove the remaining free water and part of the cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com