Tightening mechanism for opening and closing filter press

A technology of filter press and transmission mechanism, which is applied in the direction of filtration and separation, separation methods, chemical instruments and methods, etc., can solve the problems of increased cost, increased maintenance workload, complex structure and control system, etc., and achieves large carrying capacity, The effect of simple and compact structure and large stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

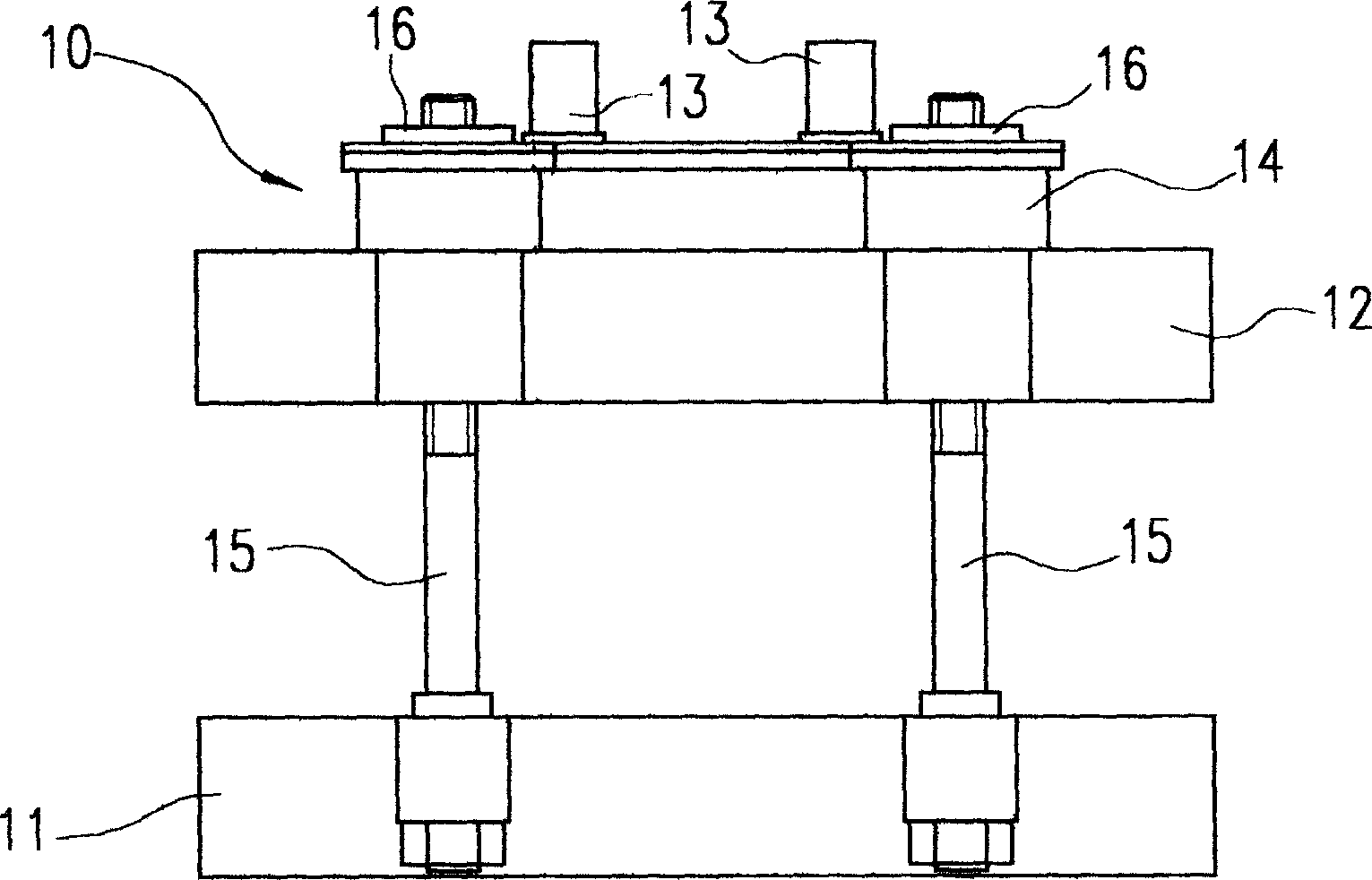

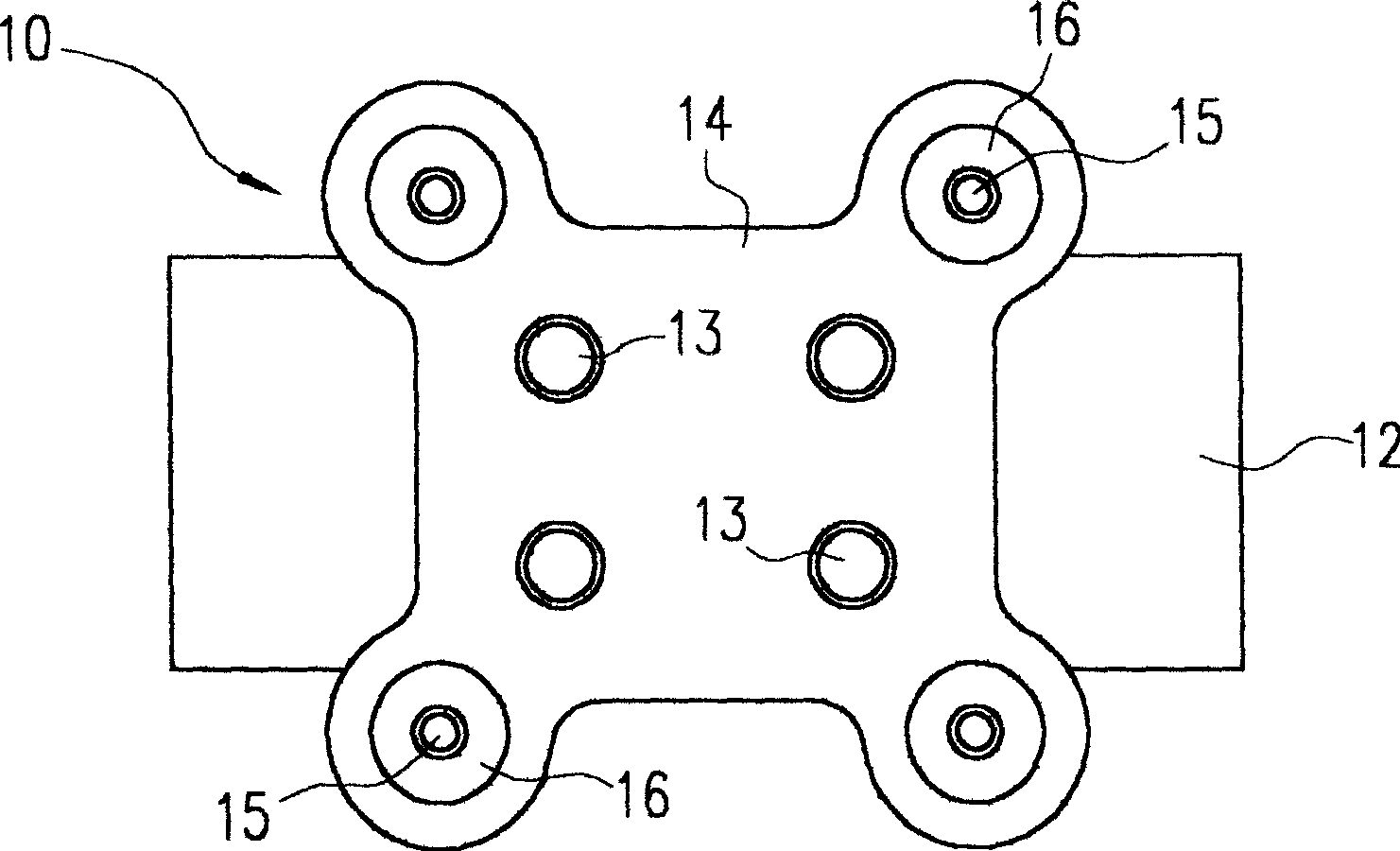

[0015] figure 1 and figure 2 An opening and closing tensioning mechanism 10 for a vertical filter press is shown. The mechanism includes a fixed pressure plate 11 located below, a pressure plate 12 located above, a transmission mechanism 14 with a prime mover 13, two pairs of screw rods 15 arranged on both sides of the pressure plate 11 and the pressure plate 12 and Nut 16. The lower end of each screw rod 15 is fixedly connected on the pressure bearing plate 11 , and the upper end with threads is equipped with a nut 16 . The prime mover 13 , the transmission mechanism 14 , and the pressing plate 12 are assembled with the nut 16 into one body. When the prime mover 13 drives all four nuts to rotate simultaneously through the transmission mechanism 14 , the pressure applying plate 12 assembled with the nuts 16 moves upward or downward together with the four nuts 16 .

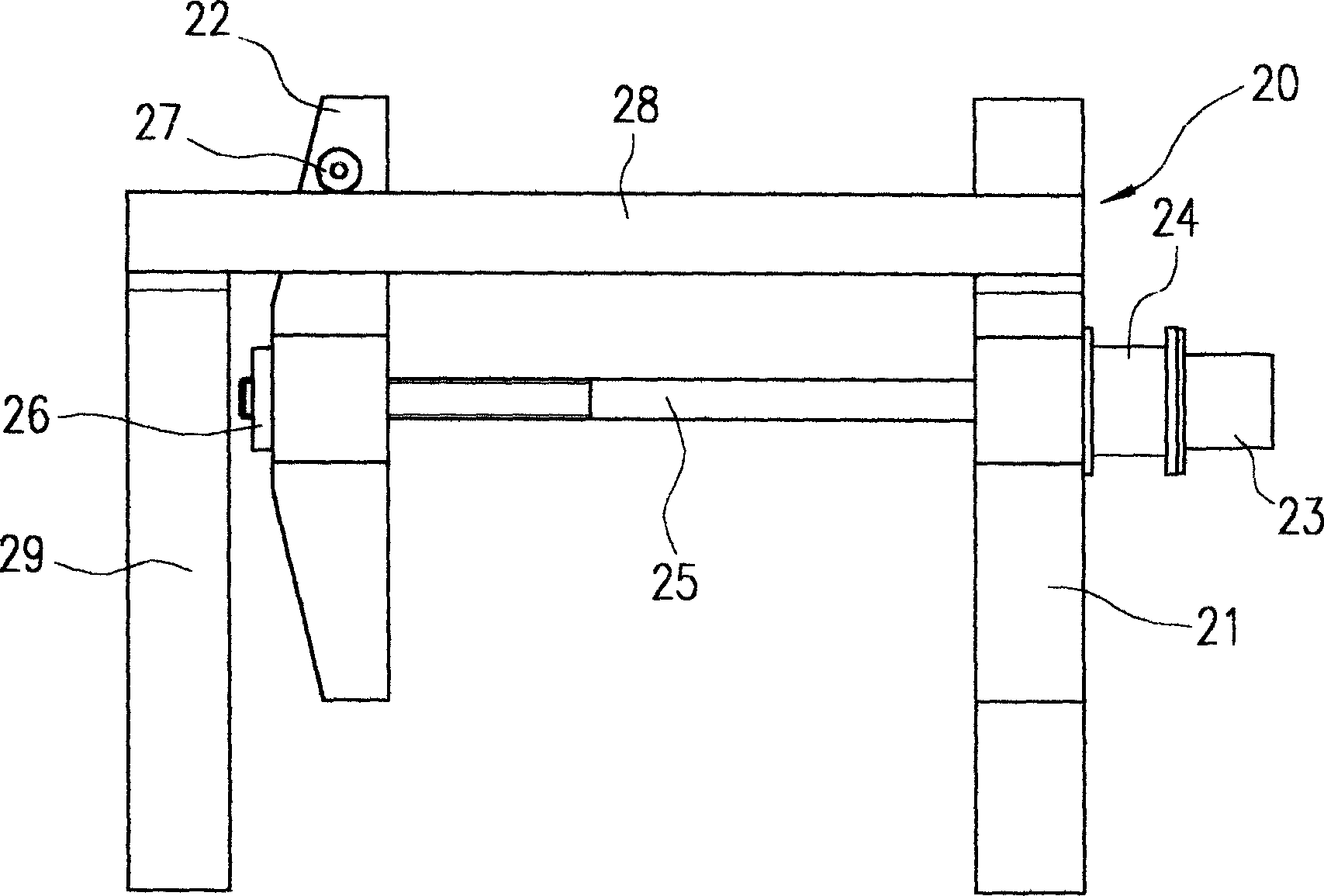

[0016] image 3 and Figure 4 An opening and closing tensioning mechanism 20 for a horizontal filter pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com