Method for optimizing scheduling system by technical imitaitng real flow

A technology for optimizing scheduling and process industry, applied in the field of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The method of the present invention is illustrated by taking a pharmaceutical production workshop as an example in conjunction with the accompanying drawings.

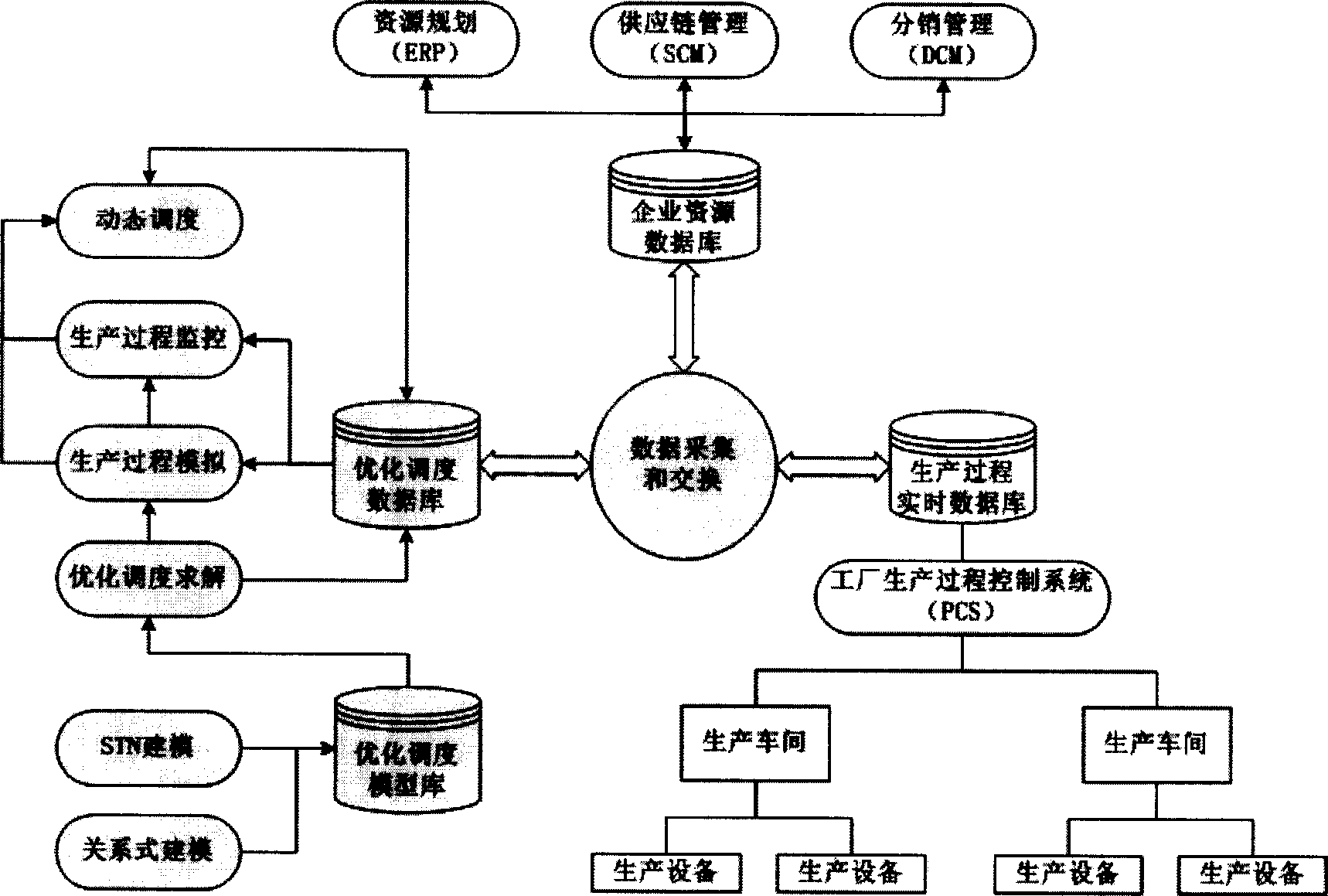

[0030] figure 1 Describes the specific modules of each step of the dispatching method and the diagram of the relationship with the upper layer ERP, SCM, DCM and the lower layer production process monitoring. First, collect the basic attributes and constraints of a drug and its raw materials, production equipment, storage devices, etc., as well as the sales plan, raw material procurement plan and equipment maintenance plan of the drug, establish the basic data of the production scheduling system, and carry out the production process of the drug. Visual modeling, you can choose production process flow chart description modeling or production process relational modeling; then according to the sales plan of the drug, raw material procurement plan, equipment maintenance plan, intermediate and raw material inventory i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com