Inertia drive torque transmission level control and engine starter incorporating same

A technology for torque transmission and starter, which is applied in the direction of engine starting, starting device with manual crank, starting device with mechanical power storage, etc., which can solve problems such as increasing the cost of the drive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

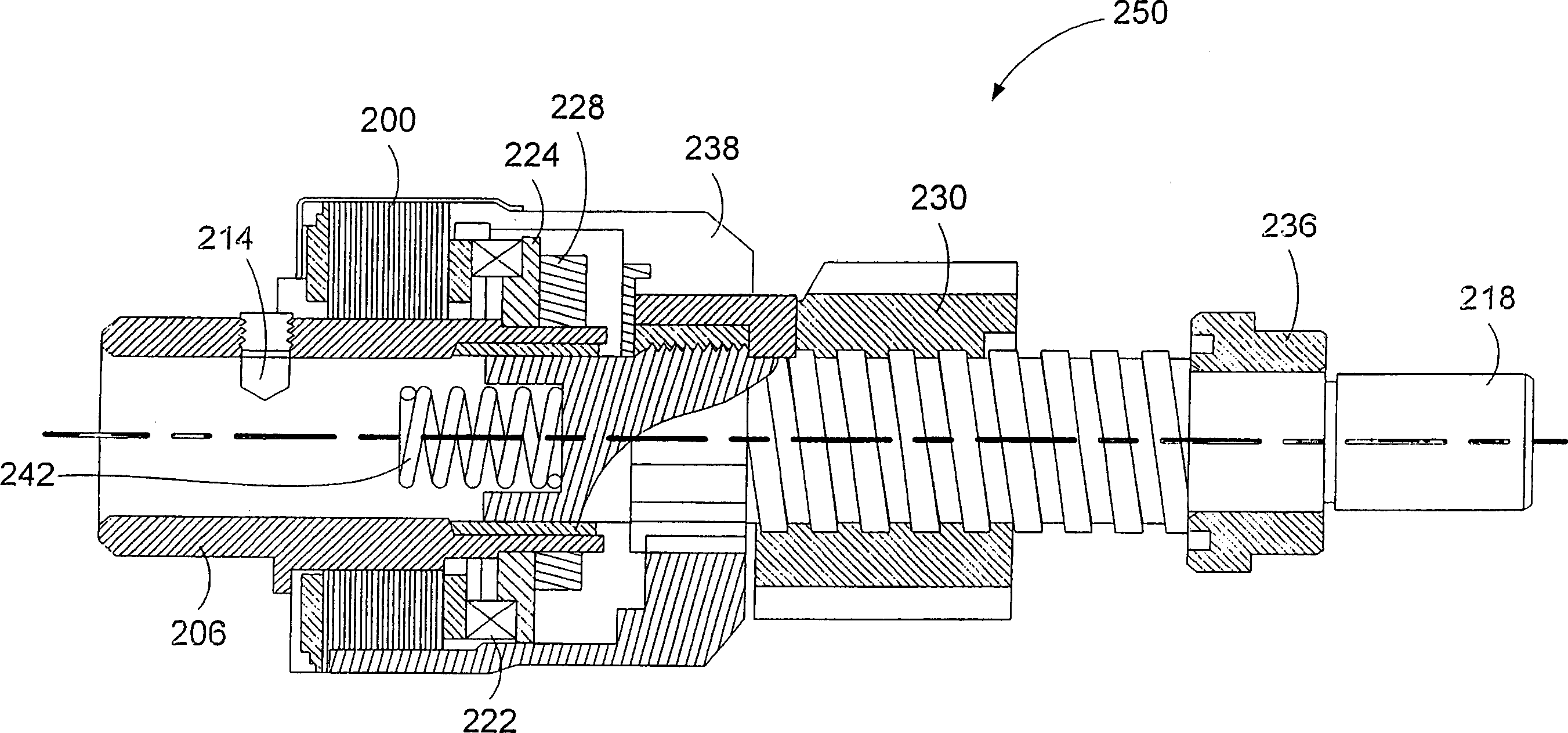

[0029] As noted above, one problem with conventional engine starter inertia drives is the uncontrollable nature of the torque for clutch plate slip. Such uncontrollable torque values lead to increased wear of the clutch plates, if the torque values at which slip occurs are too low, and to increased stress on starter and engine components if the torque values at which slip occurs are too high. An additional problem associated with this conventional engine starter drive is the cost of the six compression springs required to maintain force on the clutch stack. In order to overcome these problems, the focus of research and development is that the traditional engine starter driver cannot control the torque generated by the slippage to the engine starter inertial driver of the present invention in an acceptable and narrow range.

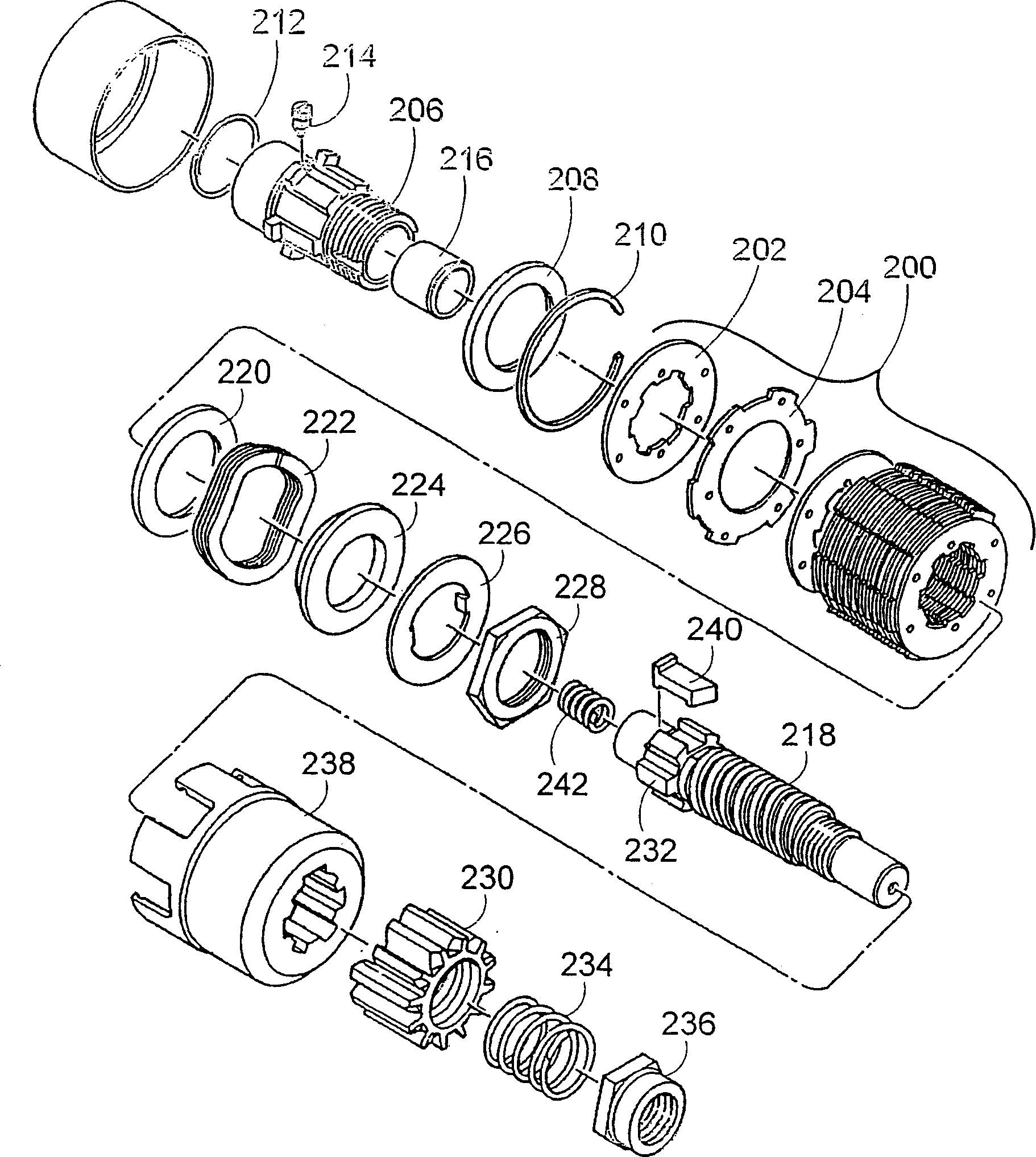

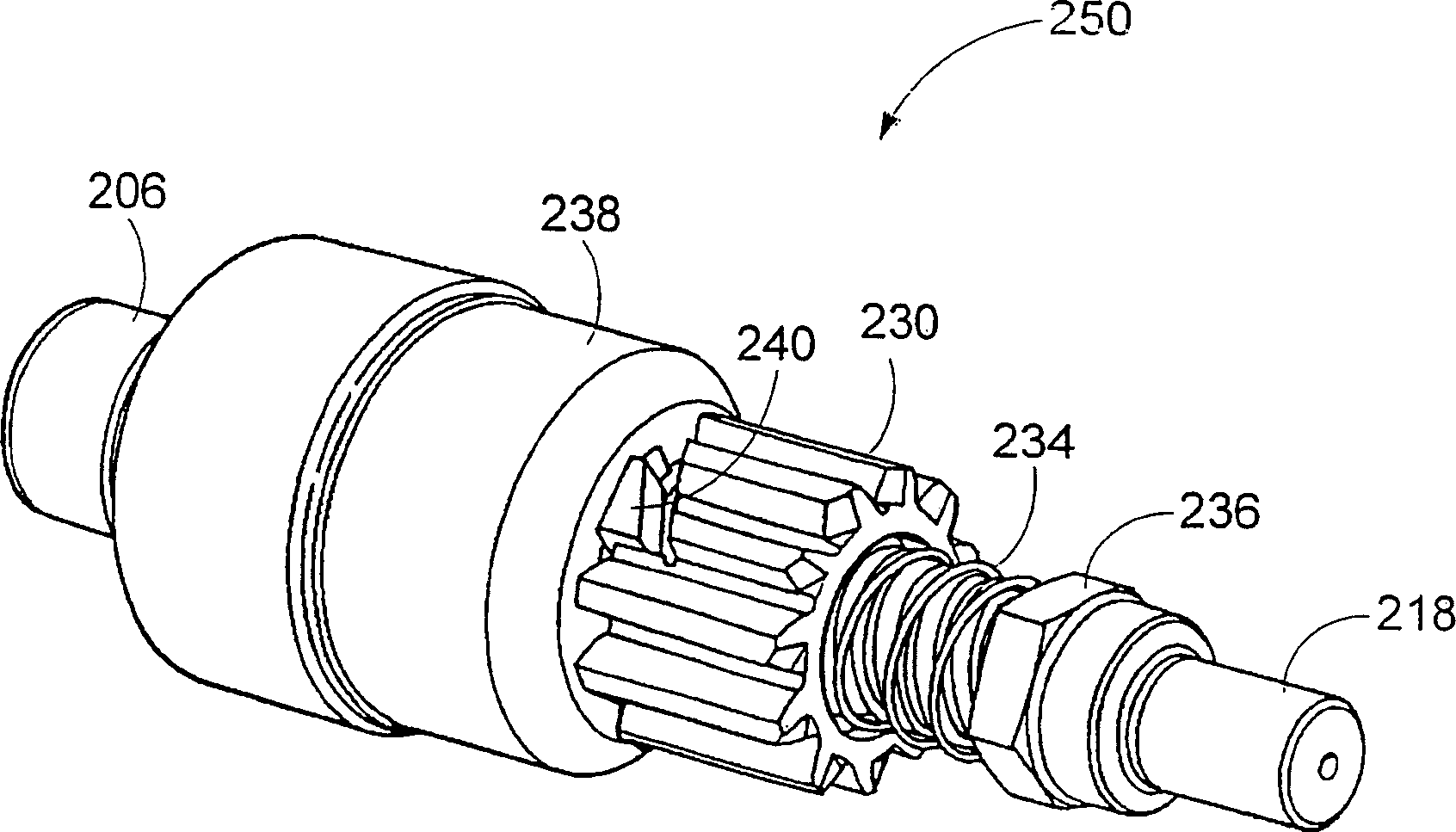

[0030] refer to figure 1 , illustrates an embodiment of an exploded three-dimensional form according to the invention. Such as figure 1 As can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com