Gas injection port structure of flat fluorescent lamp

一种充气口、荧光灯的技术,应用在电管/灯排气、电管/灯填充、放电管/灯的制造等方向,能够解决难玻管23充入惰性气体、平面荧光灯FFL20难制造、降低效率等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Preferred embodiments of the present invention will now be described in detail with reference to the accompanying drawings. Wherever possible, the same parts have been designated by the same or like reference numerals throughout the drawings.

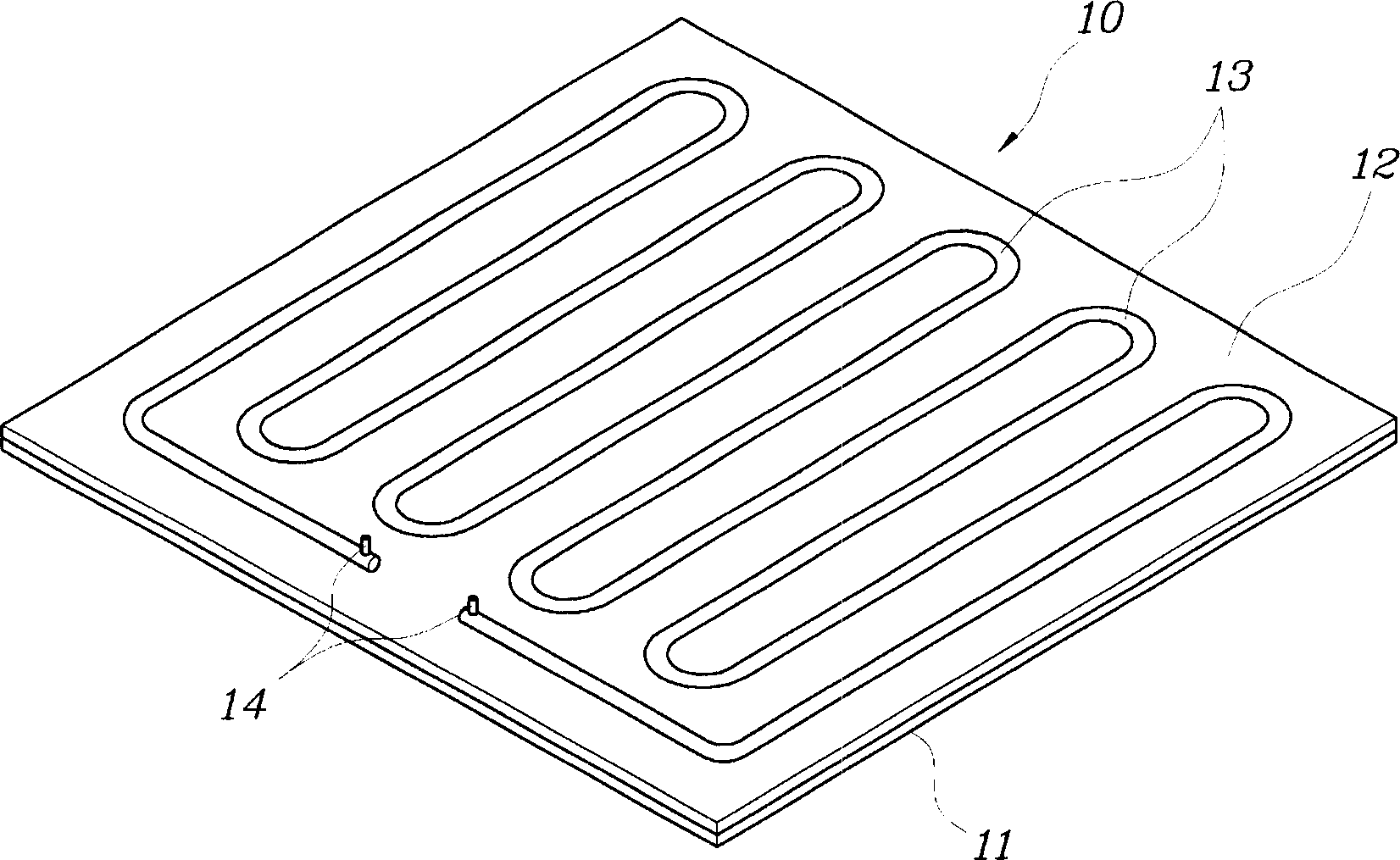

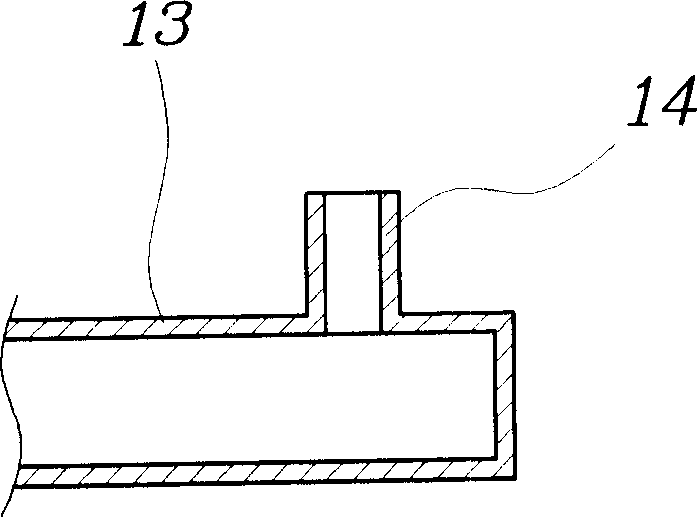

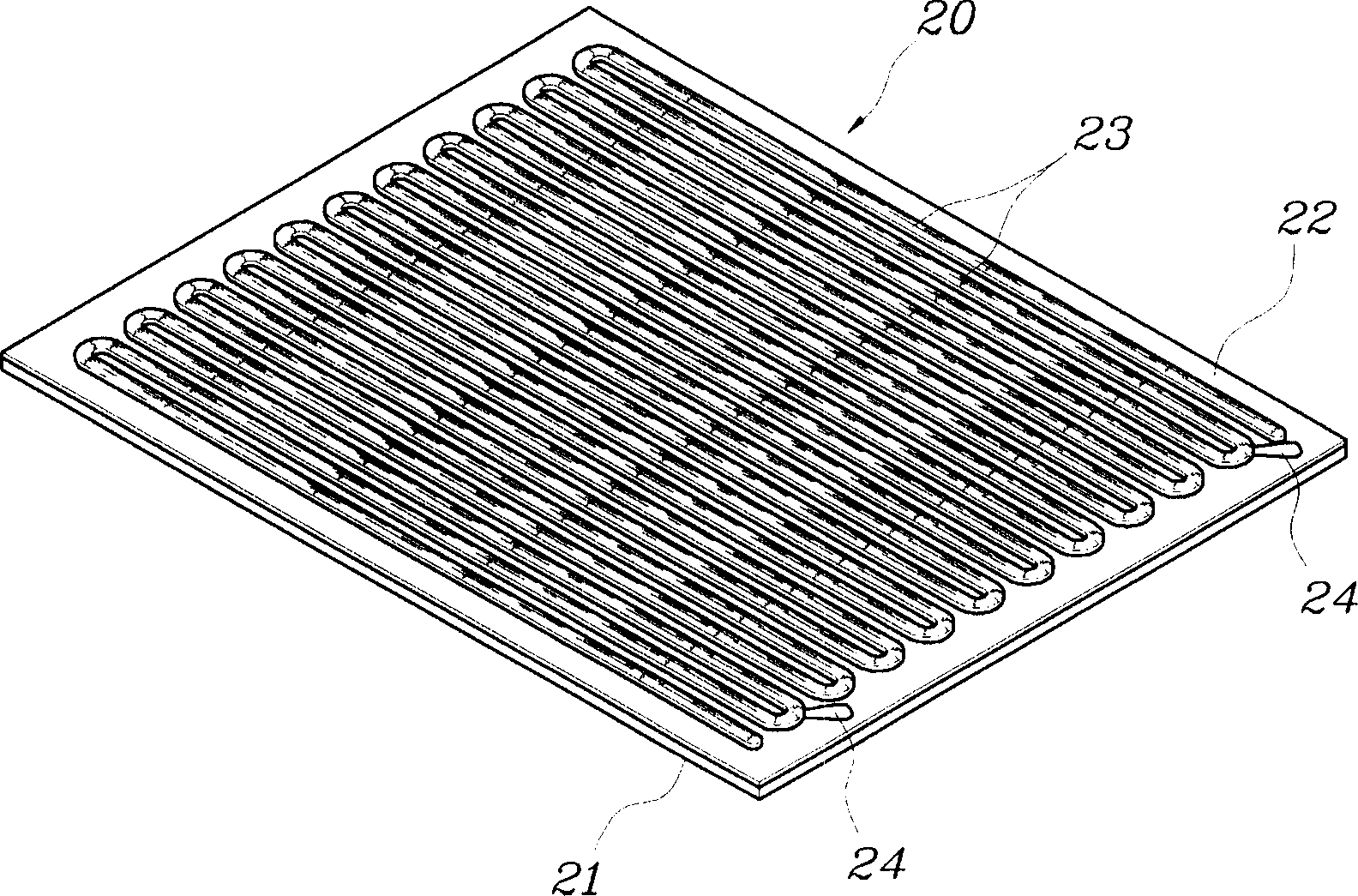

[0028] Figure 6 is a perspective view of the structure of the flat fluorescent lamp FFL according to the first embodiment of the present invention. Figure 7 yes Figure 6 A cross-sectional view of the gas filling port of the flat fluorescent lamp FFL shown in .

[0029]As shown in the figure, according to the gas filling port structure of the flat fluorescent lamp FFL 20 according to the first embodiment of the present invention, only one gas filling port 40 is formed at a predetermined position on the upper plate 22 . Specifically, the gas charging port 40 is formed on the upper plate 22 at a position outside the protruding glass tube 23 , thus allowing the gas charging port 40 to communicate with the inner space S of the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com