Improved method of impression testing function for material tester and improving device thereof

A material testing machine and testing function technology, applied in the direction of testing material hardness, etc., can solve the problem that the change of mechanical properties of loading and unloading materials cannot be reflected in real time, it is difficult to determine the starting point of the residual indentation diagonal, and the material testing machine can be widened. problems, to achieve accurate and reliable measurement, avoid measurement errors, and eliminate errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Preferred embodiments of the present invention are described in detail below in conjunction with accompanying drawing:

[0039] The flow process of the improved test method of the indentation test function of the material testing machine provided by the present invention is as follows: Figure 9 As shown, the specific steps are as follows:

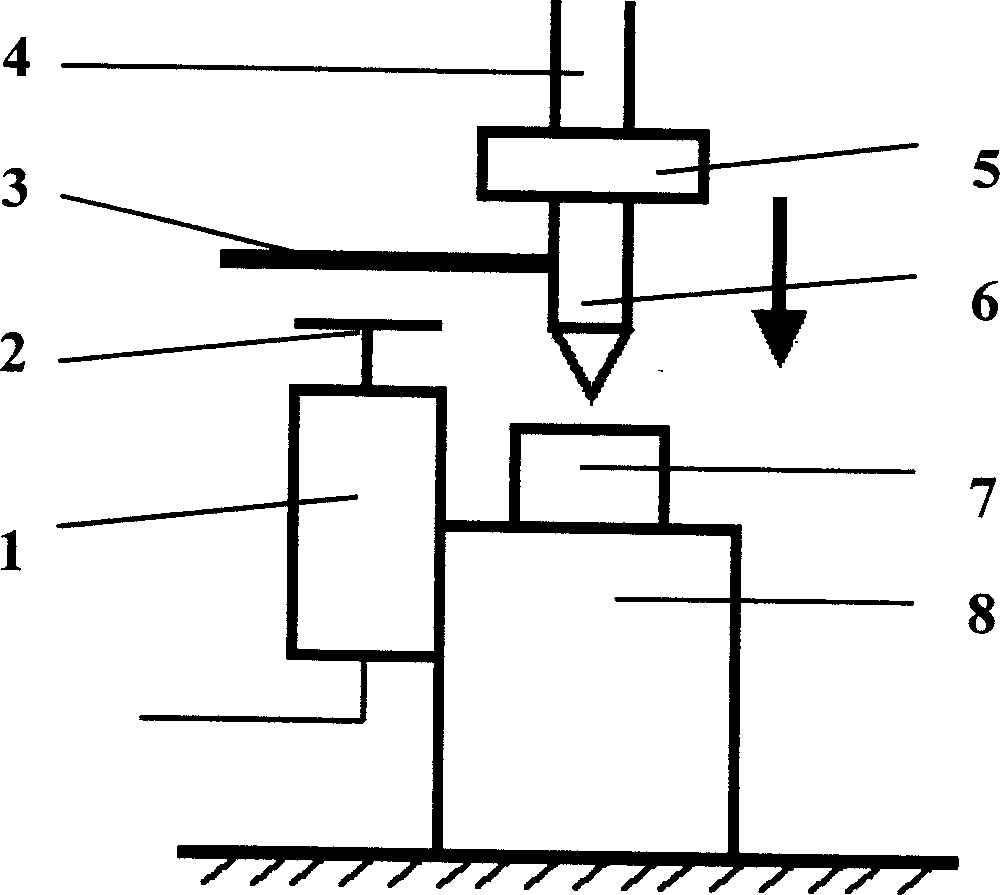

[0040]Step 100: Fix the sample on the sample stage with the test surface facing upward, install the indenter under the load sensor, install a non-contact displacement sensor on the sample stage, and start the material testing machine to load the sample.

[0041] Step 101: Use the signal acquisition module of the computer to collect the load sensor signal of the material testing machine and the signal of the additional non-contact high-resolution displacement sensor in the present invention.

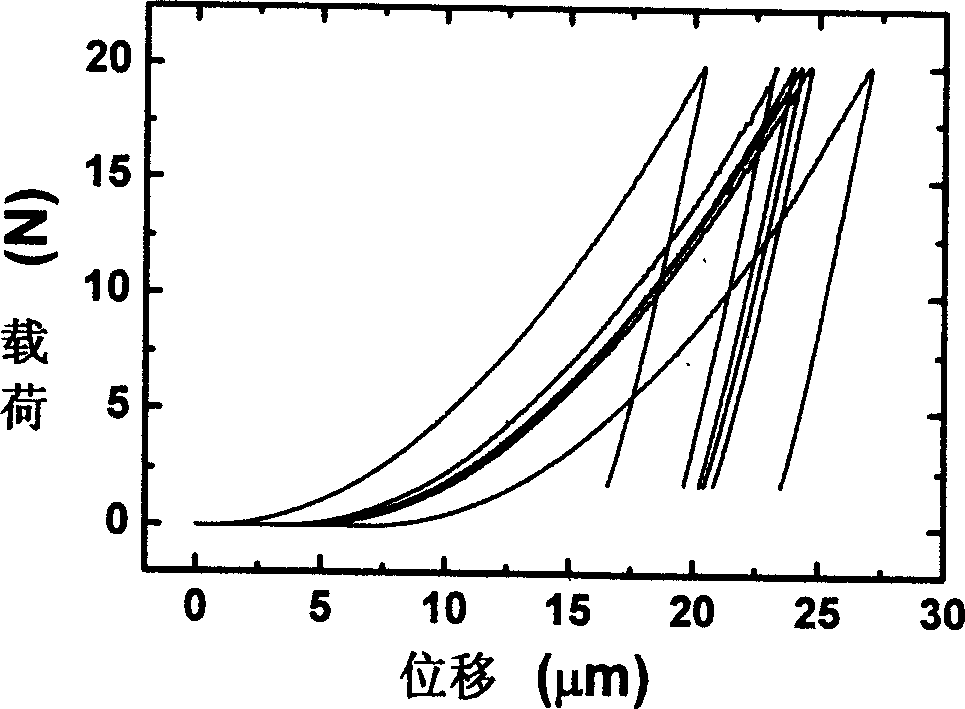

[0042] Step 102: The collected signal of the load sensor and the signal of the displacement sensor are converted to obtain the load and displ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com