Coating system for protective layer forming material

A protective layer and coating technology, applied in the field of coating systems, can solve the problems of long vehicle transmission lines, reduced production efficiency, and inability to complete the coating process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Next, preferred embodiments of a coating system for a protective layer forming material according to the present invention will be described with reference to the accompanying drawings.

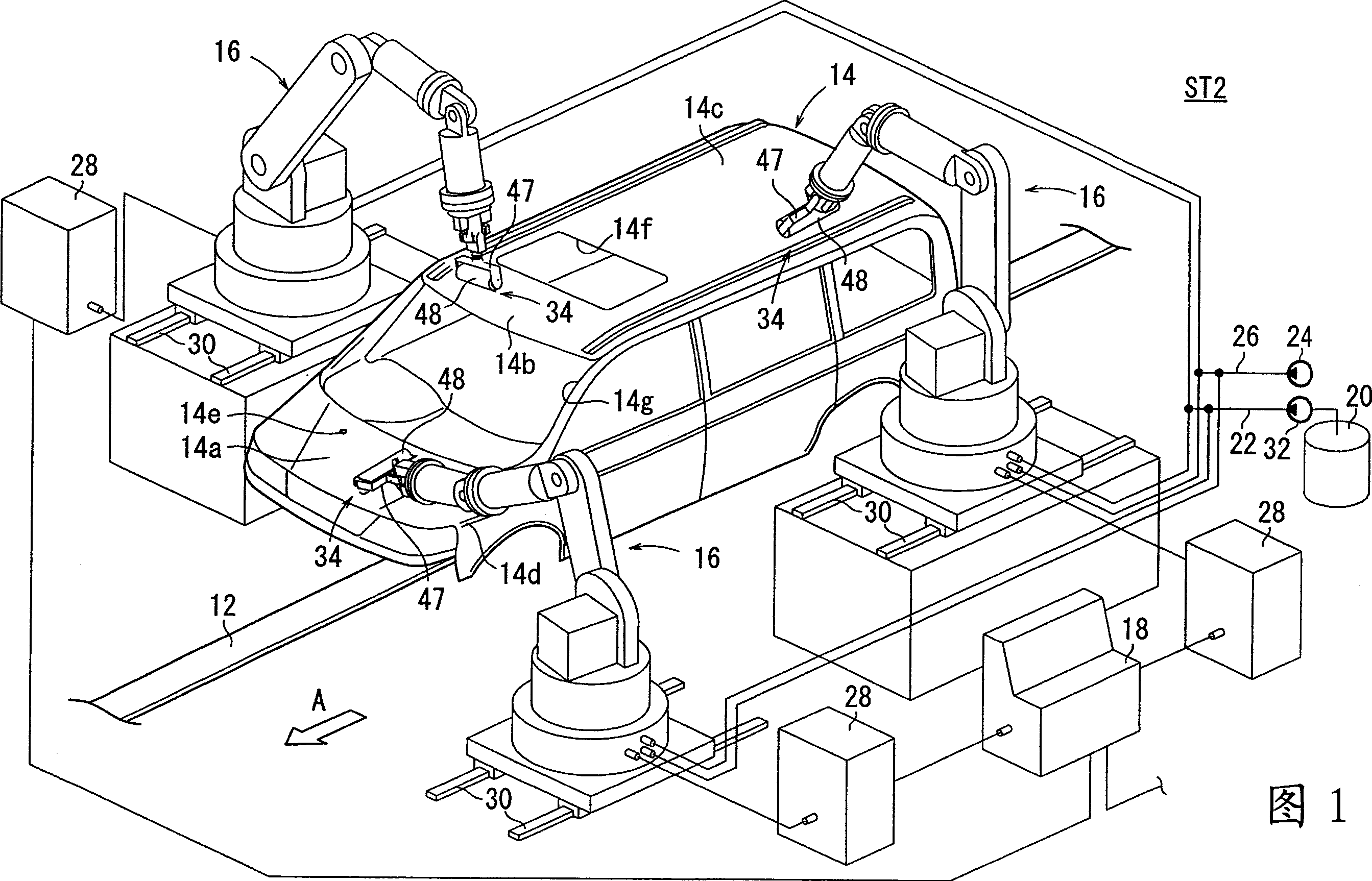

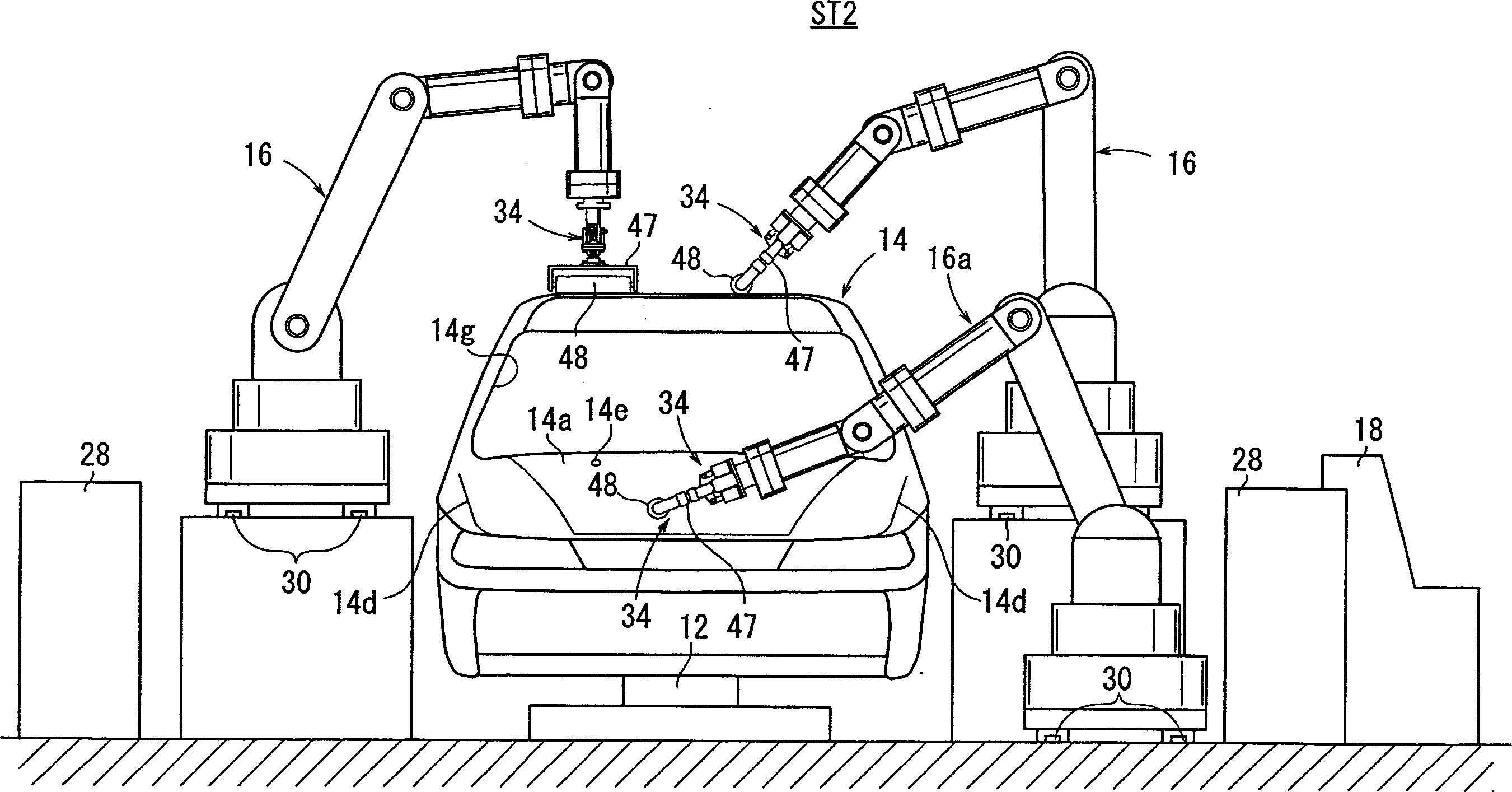

[0052] First, the first coating station ST1, the second coating station ST2, and the third coating station ST3 incorporated in the coating system 10a for a protective layer forming material according to the first embodiment will be described below, which The coating stations are arranged sequentially along the conveying direction. Representative coating system 10a (see Figure 5 ) The second coating station ST2 of the coating station will be described.

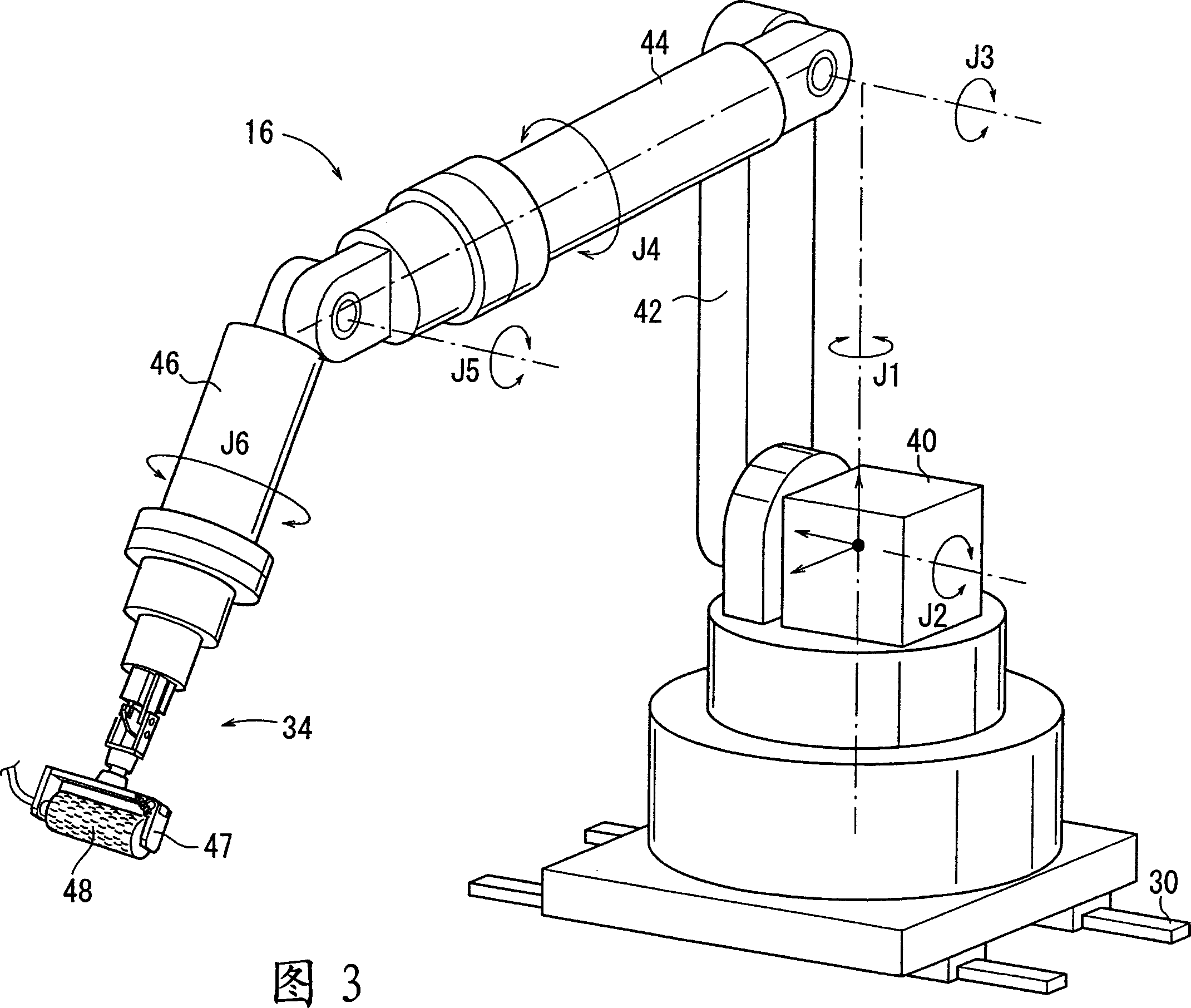

[0053] Figure 1 and figure 2 As shown, the second coating station ST2 is arranged on the conveying line 12 for the vehicle 14 and coats the painted vehicle 14 with the protective layer forming material. The second coating station ST2 includes three industrial articulated robots (coating equipment) 16, a console 18 for controlling th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com