M-shape water seal floor drain

A technology for sealing floor drains and floor drains, which is used in water supply installations, indoor sanitary piping installations, buildings, etc., can solve the problems of easy expansion and deformation, poor corrosion resistance, short service life, etc., and achieves small thermal expansion deformation and good corrosion resistance. , the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

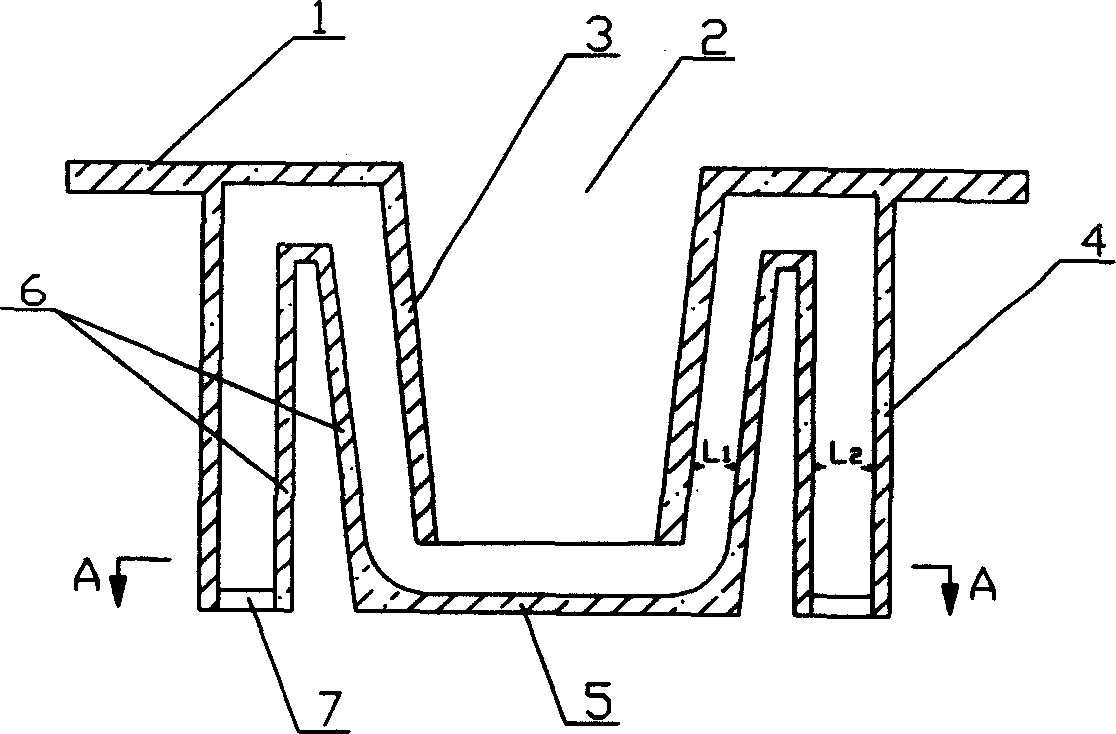

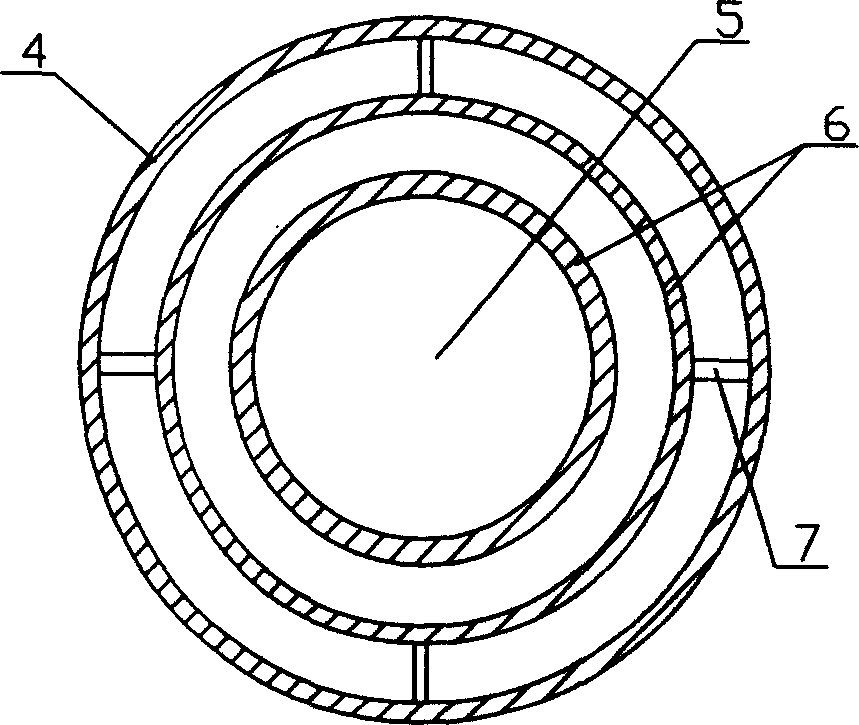

[0021] like figure 1 , 2 The shown embodiment 1 of the water-sealed floor drain of the present invention includes a top plate 1 and a cup body, and a water inlet 2 is opened on the top plate 1; the water inlet cylinder 3 surrounding the water inlet 2 is connected to the bottom of the top plate 1 and the surrounding water inlet cylinder The water outlet cylinder body 4 of the body 3. The cup body is arranged under the top plate 1, and the cup body is composed of a cup bottom 5 and a cup wall 6, and the cup wall 6 is inserted into the gap between the water inlet cylinder 3 and the water outlet cylinder 4; the top of the cup wall 6 is connected to the top plate 1 There is a gap between the bottom surfaces, and there is a gap between the bottom of the water inlet cylinder 3 and the bottom 5 of the cup. The distance L between the water inlet cylinder 3 and the cup wall 6 1 Less than the distance L between the water outlet cylinder 4 and the cup wall 6 2 .

[0022] like figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com