Method of vacuum nitrogen-filled packing food superfine powder and products therefrom

A technology of nitrogen-filled packaging and fine powder, which is applied in the direction of packaging, transportation and packaging, and special packaging objects under vacuum/special atmosphere. It can solve the problems of unrealizable caliber, short shelf life, and anti-oil phenomenon, etc., so as to facilitate large-scale promotion , easy to use, anti-pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

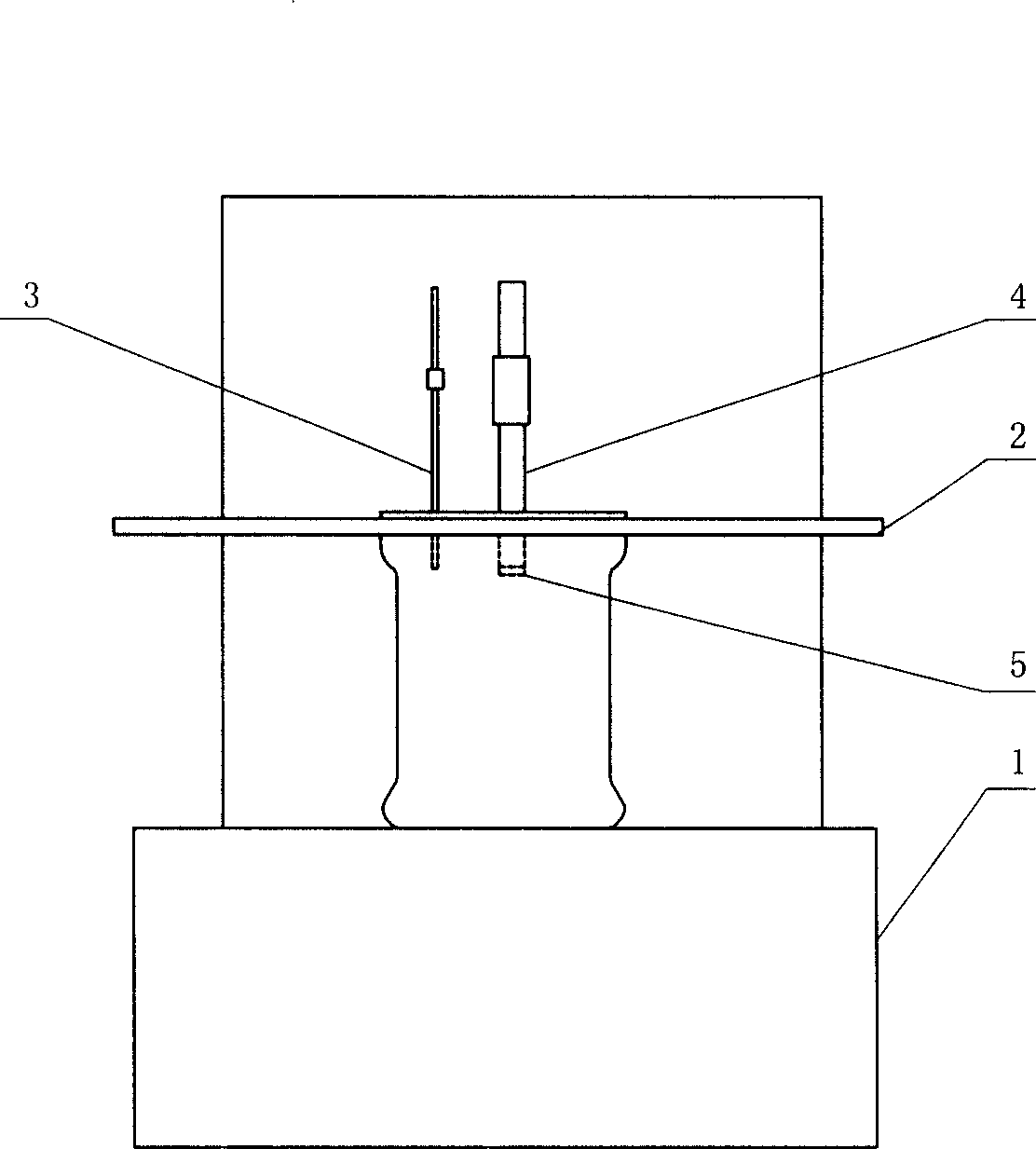

[0020] Such as figure 1 The nozzle-type vacuum device shown includes a frame 1, a sealing clamp 2 is arranged on the frame 1, a nitrogen filling nozzle 3 and a vacuum nozzle 4 are arranged above the sealing clamp 2, and a filter screen 5 is arranged at the lower end of the vacuum nozzle 4. The pore size is smaller than the diameter of the fine powder.

[0021] The method of the present invention includes the following steps:

[0022] 1. Pack the powdered product into the packaging bag;

[0023] 2. Insert the nitrogen filling nozzle 3 and the vacuum nozzle 4 into the packaging bag;

[0024] 3. Use the vacuum nozzle 4 to vacuum, and then use the nitrogen filling nozzle 3 to fill the bag with nitrogen;

[0025] 4. Repeat step 3 twice and vacuum again;

[0026] 5. Withdraw the nitrogen filling nozzle and vacuum nozzle;

[0027] 6. Seal the bag opening.

[0028] When vacuuming for the first time, suck up the air in the upper part of the packaging bag. When filling nitrogen for the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com