Piston type compressor and assembling method thereof

A compressor and piston technology, applied in the field of piston compressors, can solve problems such as deformation, harmfulness, and troublesome fixing solutions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

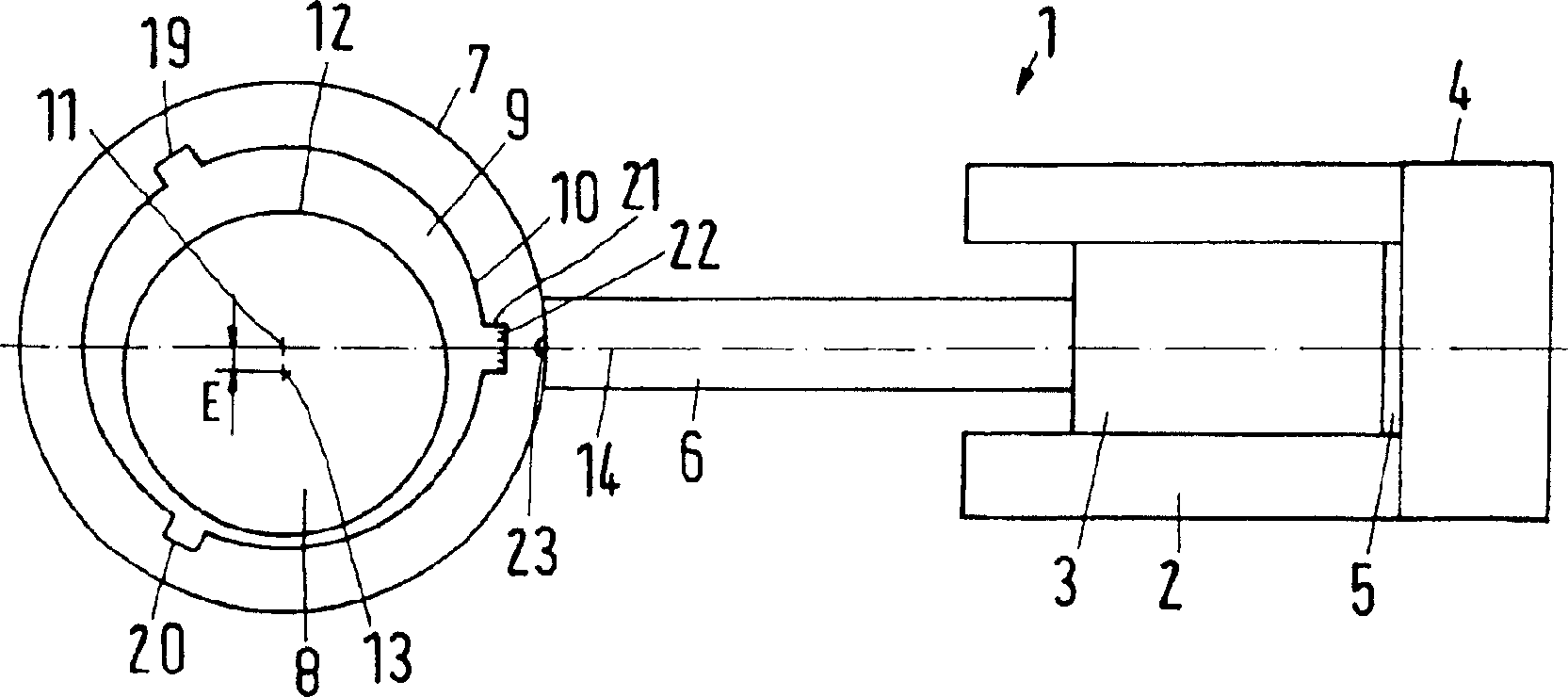

[0028] figure 1 A refrigerant compressor 1 is shown schematically and thus greatly simplified as an exemplary embodiment of a piston compressor. The refrigerant compressor 1 has a cylinder 2 in which a piston 3 can reciprocate. The cylinder 2 is closed by a cylinder head 4 . Cylinder 2, piston 3 and cylinder head 4 constitute the boundary of compression chamber 5, when piston 3 moves to the right (for figure 1 In terms of) the refrigerant gas is compressed in it as it moves.

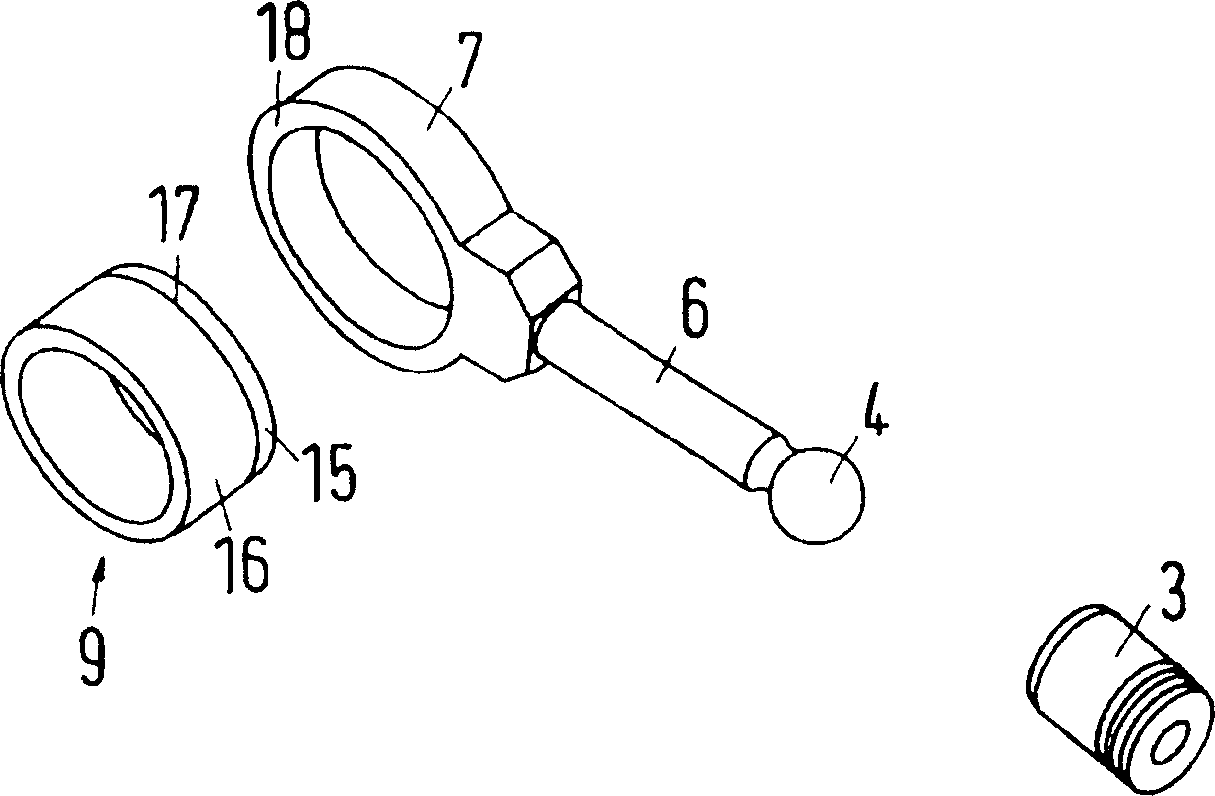

[0029] The piston 3 is driven by a connecting rod 6 whose piston-side end is hinged to the piston 3 in a manner not further shown in the figures. At its other end, the connecting rod 6 has a connecting rod bore 7 which surrounds a crank pin 8 . The figure shows that the connecting rod hole 7 is closed in the circumferential direction. But this is not strictly required.

[0030] An axle sleeve 9 is adorned between the connecting rod hole 7 and the crank pin 8 . The sleeve has an outer wall 10 of ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com