Collapsible nut

A nut, threaded wall technology, used in nuts, threaded fasteners, connecting components, etc., can solve problems such as high cost and humming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Although the present invention may be embodied in various forms, it is to be understood that the particular embodiments shown in the drawings and described in detail herein are only illustrative of the principles of the invention and are not intended to limit the invention thereto.

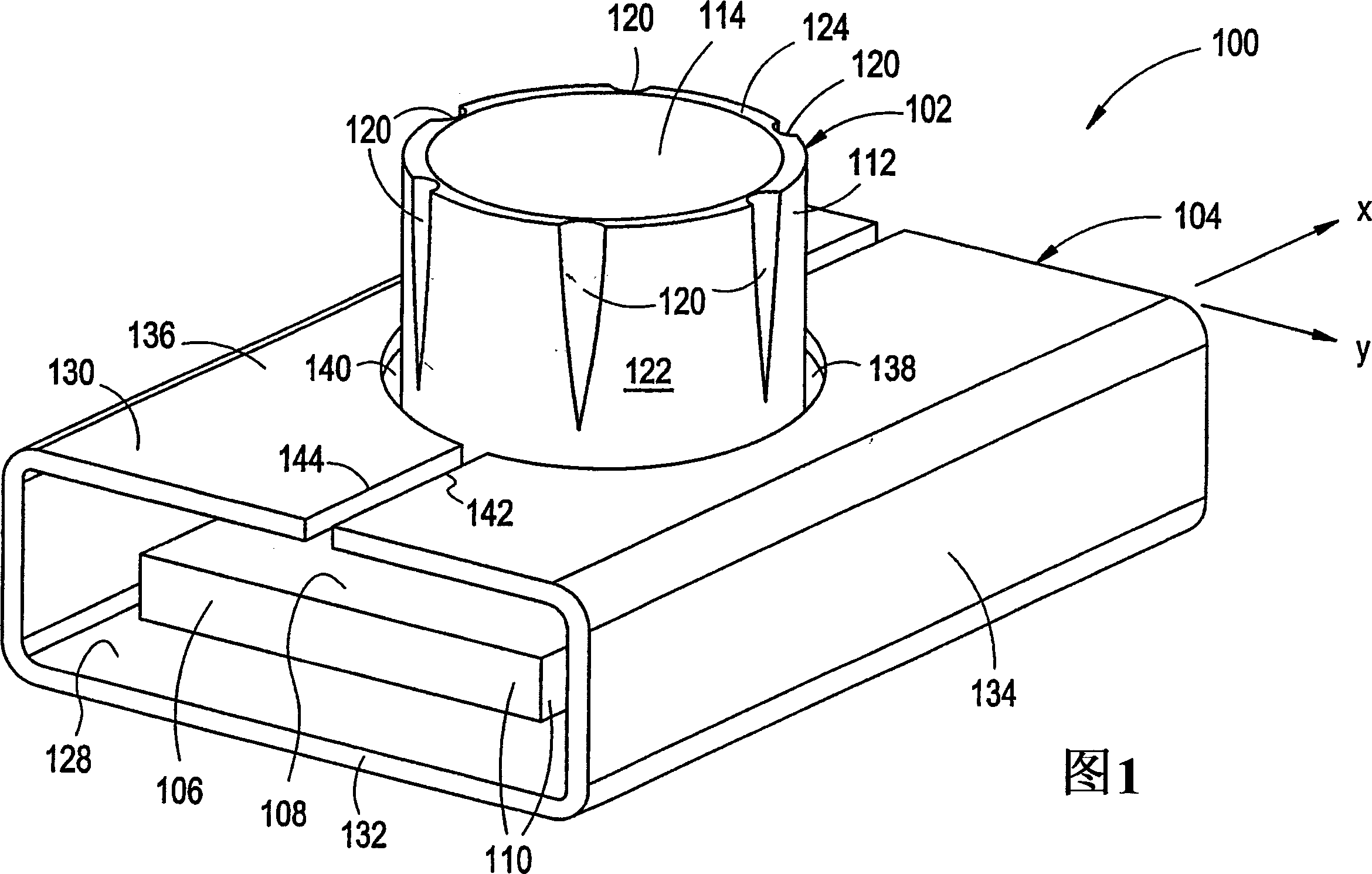

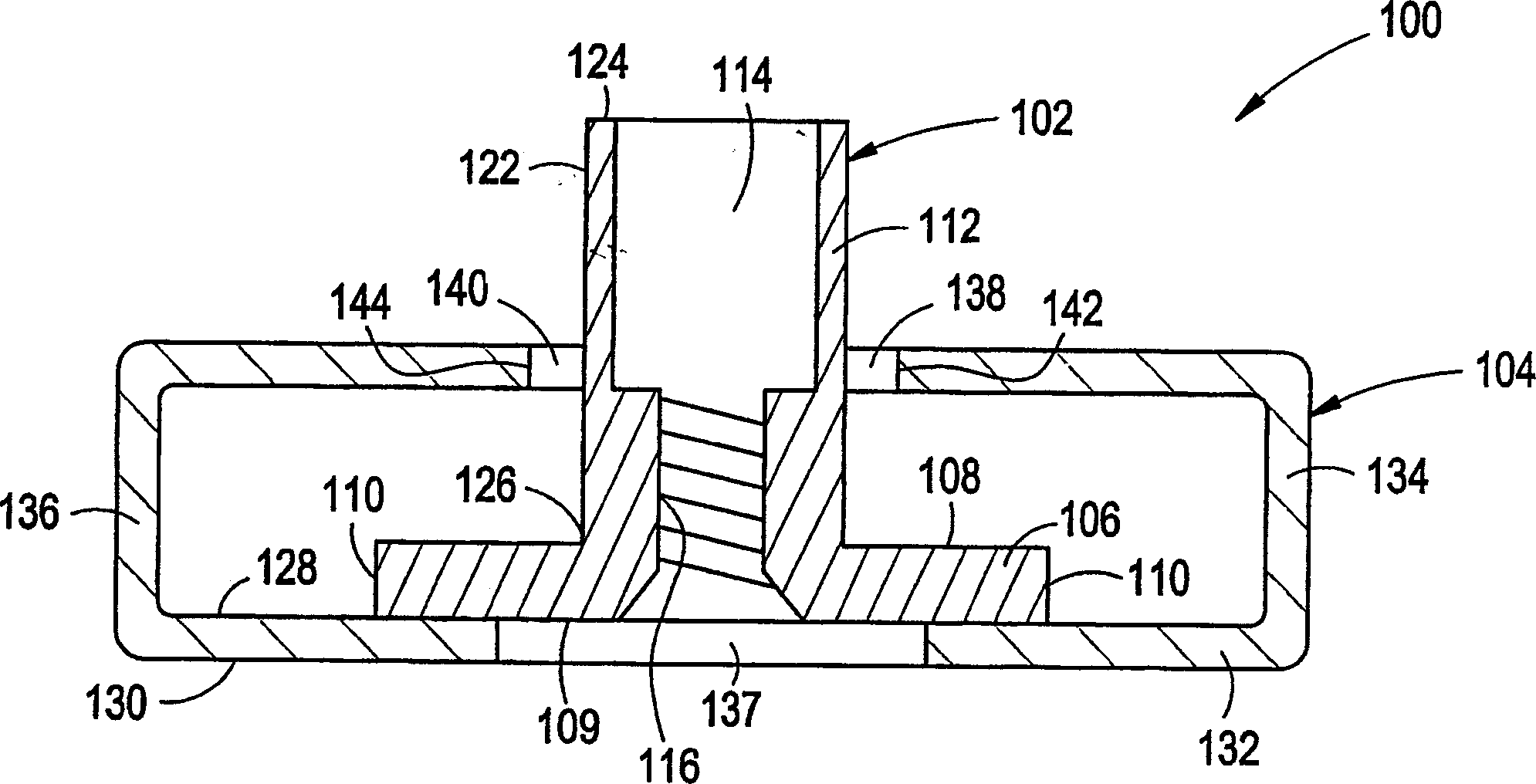

[0047] Several different embodiments of the invention are shown and described herein. Specifically, FIGS. 1-6 show a lock nut device 100 in a first embodiment of the present invention. 7-12 illustrate a cage nut arrangement 200 in a second embodiment of the present invention. 13-18 illustrate a cage nut arrangement 300 in a third embodiment of the present invention. 19-24 illustrate a cage nut arrangement 400 in a fourth embodiment of the present invention. 25-28 illustrate a cage nut arrangement 500 in a fifth embodiment of the present invention. Similar elements are denoted by like reference numerals, the first embodiment is shown with the reference numeral 100, the second embodiment i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com