Airflow vibrating type ordered seedling throwing machine

A technology of vibrating and throwing seedlings is applied in the field of agricultural machinery, which can solve the problems of raising seedling requirements, high cost, and difficulty in popularization, and achieve the effects of being favorable for popularization, low in manufacturing cost, and low in cost of seedling cultivation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with drawings and embodiments.

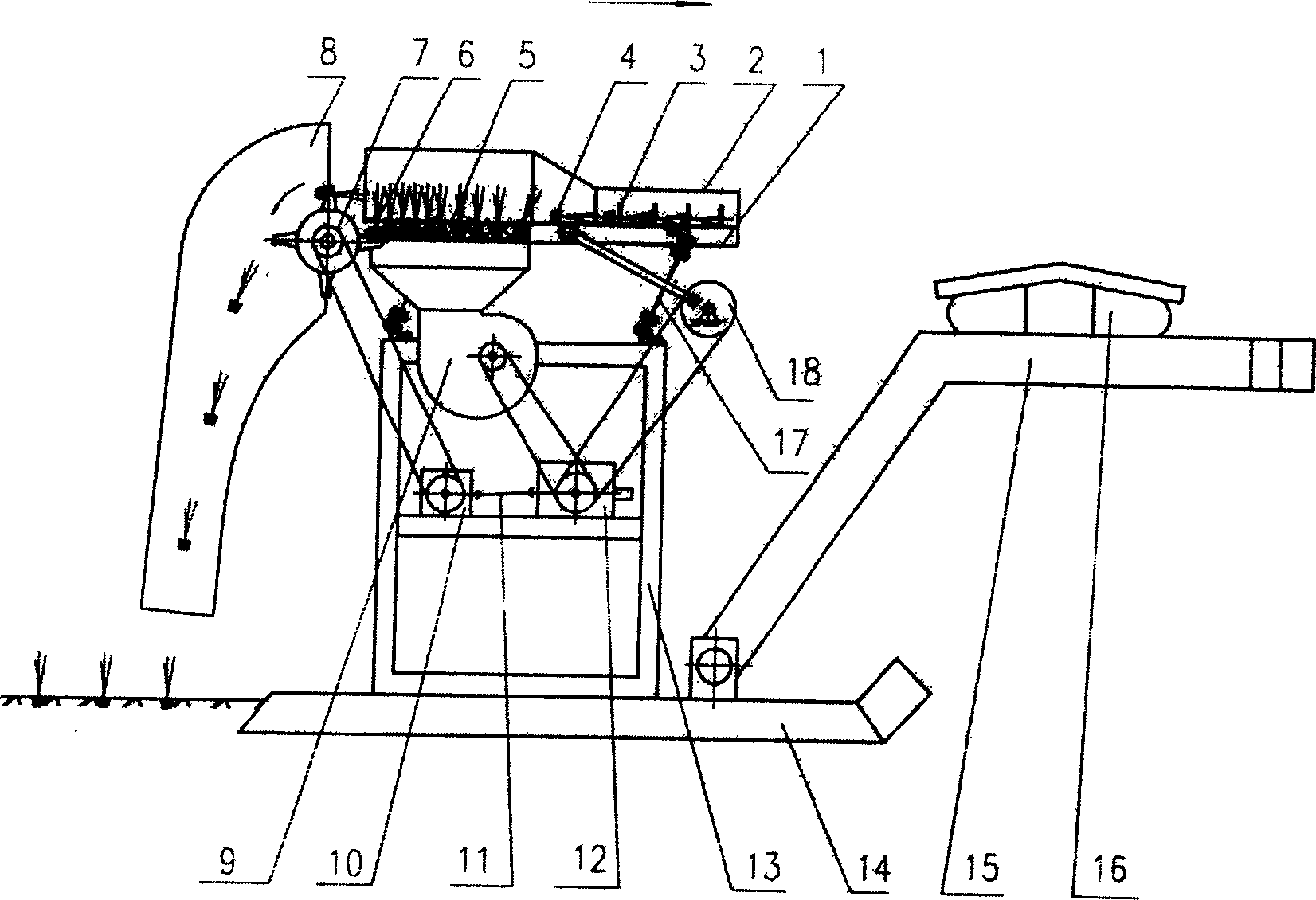

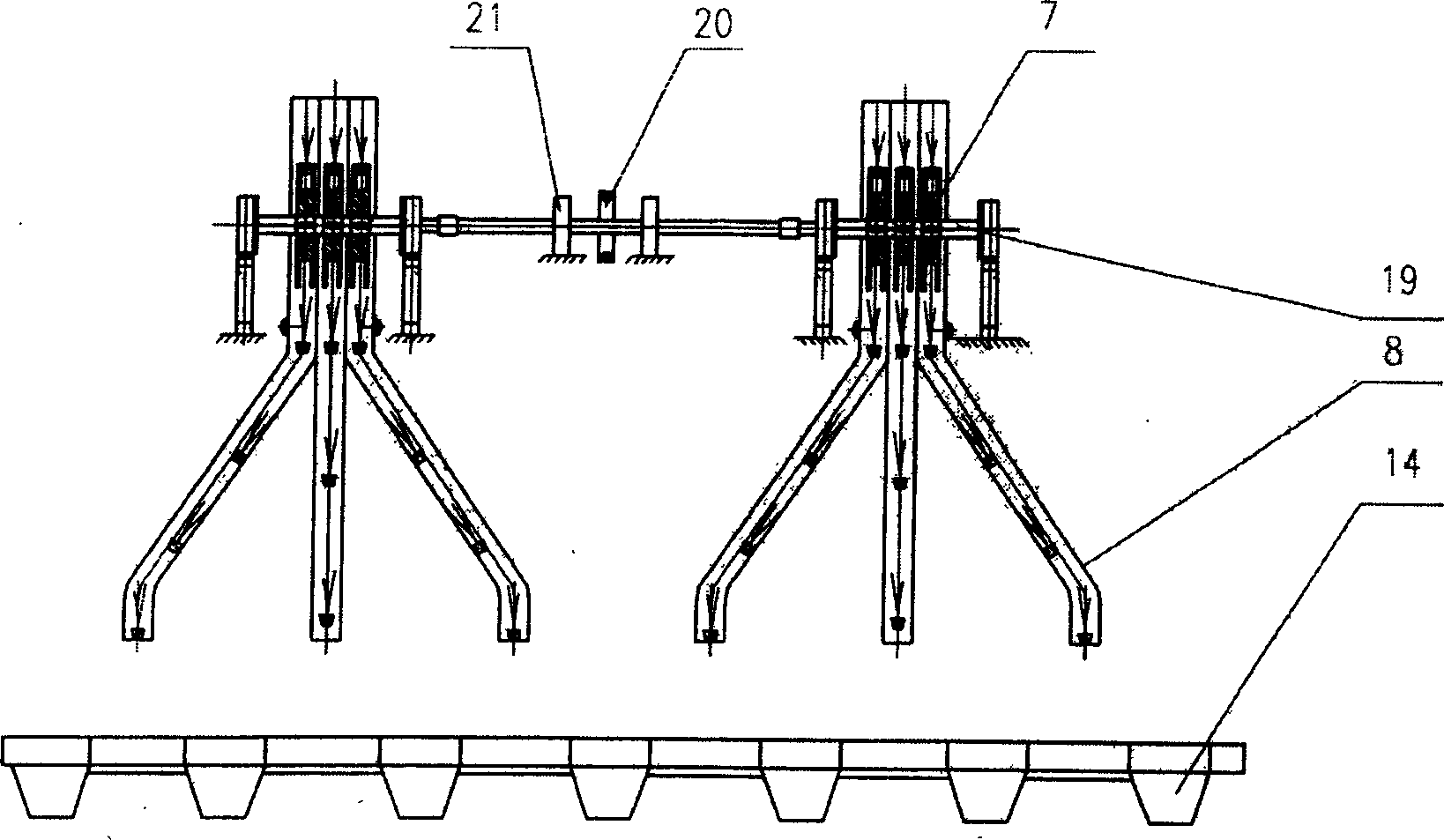

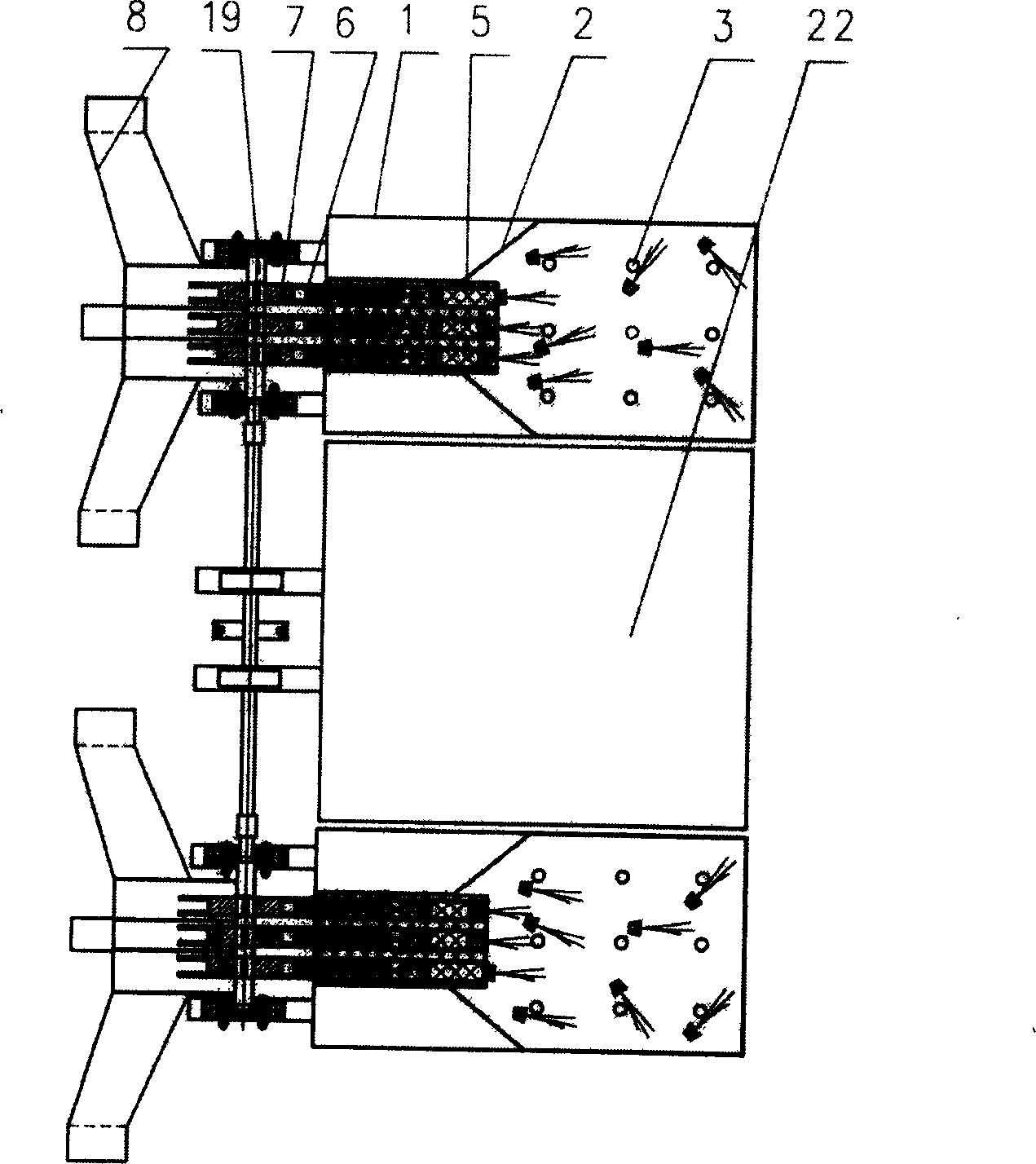

[0018] like figure 1 , figure 2 , image 3 , Figure 4 As shown, the present invention includes:

[0019] 1) Two air-flow vibration type orderly throwing and separating mechanisms with the same structure: the vibrating conveying plate 1 driven by the vibrating mechanism 18 is fixed on the frame 13 through the plate spring 17, and the vibrating conveying plate 1 enters the bowl seedling 4 and one end plate There are nail teeth 3 with a certain number and spacing on the surface, which can adjust the direction of the pot seedlings 4 under the action of inertial force. The vibrating conveying plate 1 is equipped with side baffles 2. The side baffles 2 are wider at the initial part and then gradually shrink , the rear portion of the vibrating delivery plate 1 is to allow air-flow to pass through the grid 5 that makes the pot seedlings stand upright, and its cross sectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com