Natural alta-mud modification method

A bentonite and natural technology, applied in the field of modified bentonite and its preparation, can solve the problems of high content of quartz and cristobalite, low content, insufficient awareness of the hazards of quartz and cristobalite, etc., to improve product purity, increase whiteness, Eliminates the effect of restrictions on application conditions and regions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Implement with reference to the technological process of Fig. (7).

[0063] Hebei Xuanhua natural bentonite raw ore has a water content of 24% (wt%) and contains 12.3% (wt%) of quartz and cristobalite. After selection, remove large variegated and darker soil clods and stones visible to the naked eye, and cool and dry until the moisture content is 17%, and coarsely crush until the particle size is less than 5mm. Take 1 ton and add 5 tons of demineralized water. , stirred at a stirring speed of 120rpm for 4 hours, with 5% (wt%) oxalic acid solution and 5% (wt%) disodium hydrogen phosphate solution, the pH of the slurry was adjusted under stirring conditions, to pH at 6.0 ± Within the range of 0.5, the change within 30 minutes does not exceed the range of 6.0±0.5, continue to stir for 1 hour, let stand for 3 hours, siphon the suspension, and enter the modification process. The suctioned suspension is about 4.2M 3 60 liters of 10% (wt%) NaOH solution was added at a stirri...

Embodiment 2

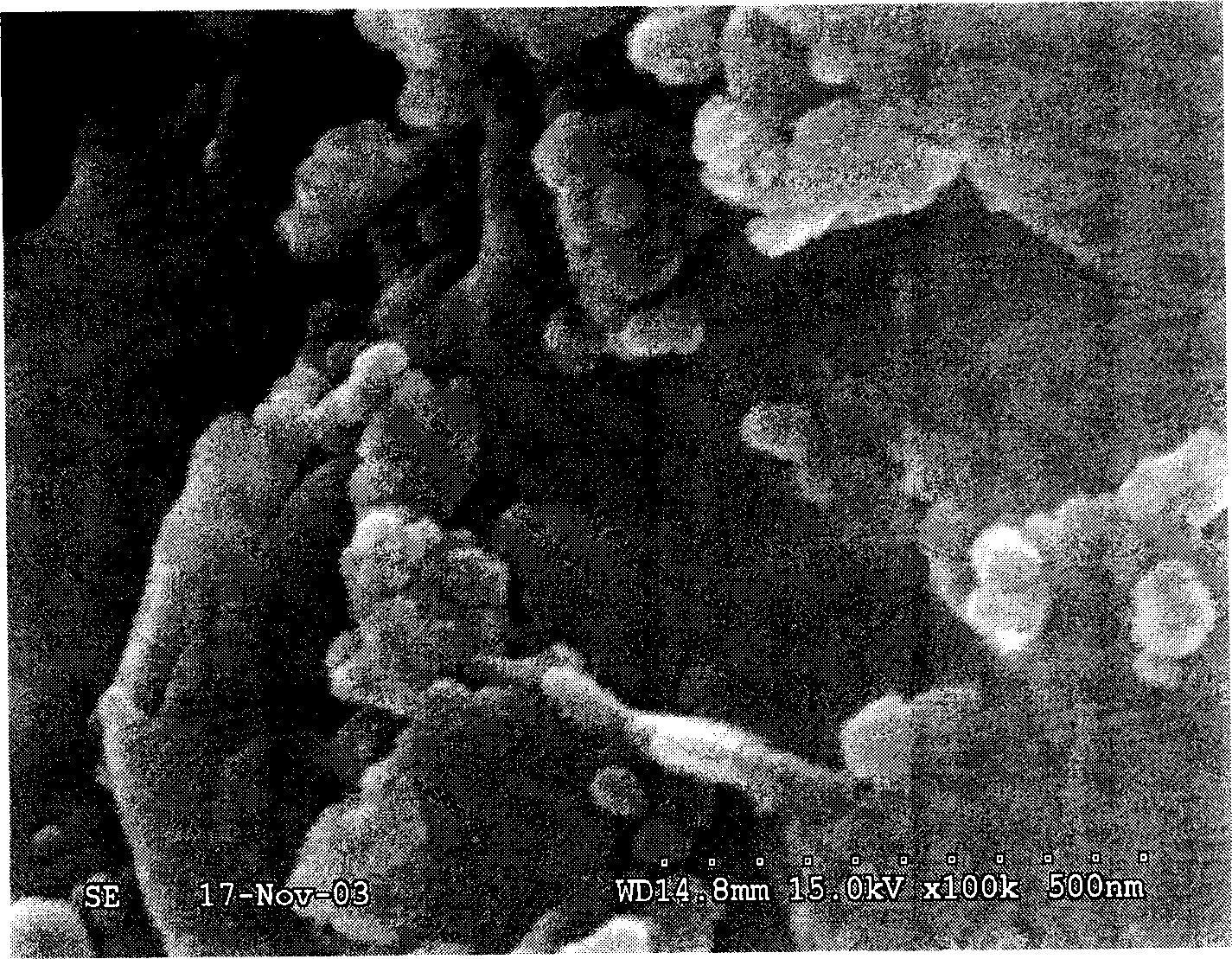

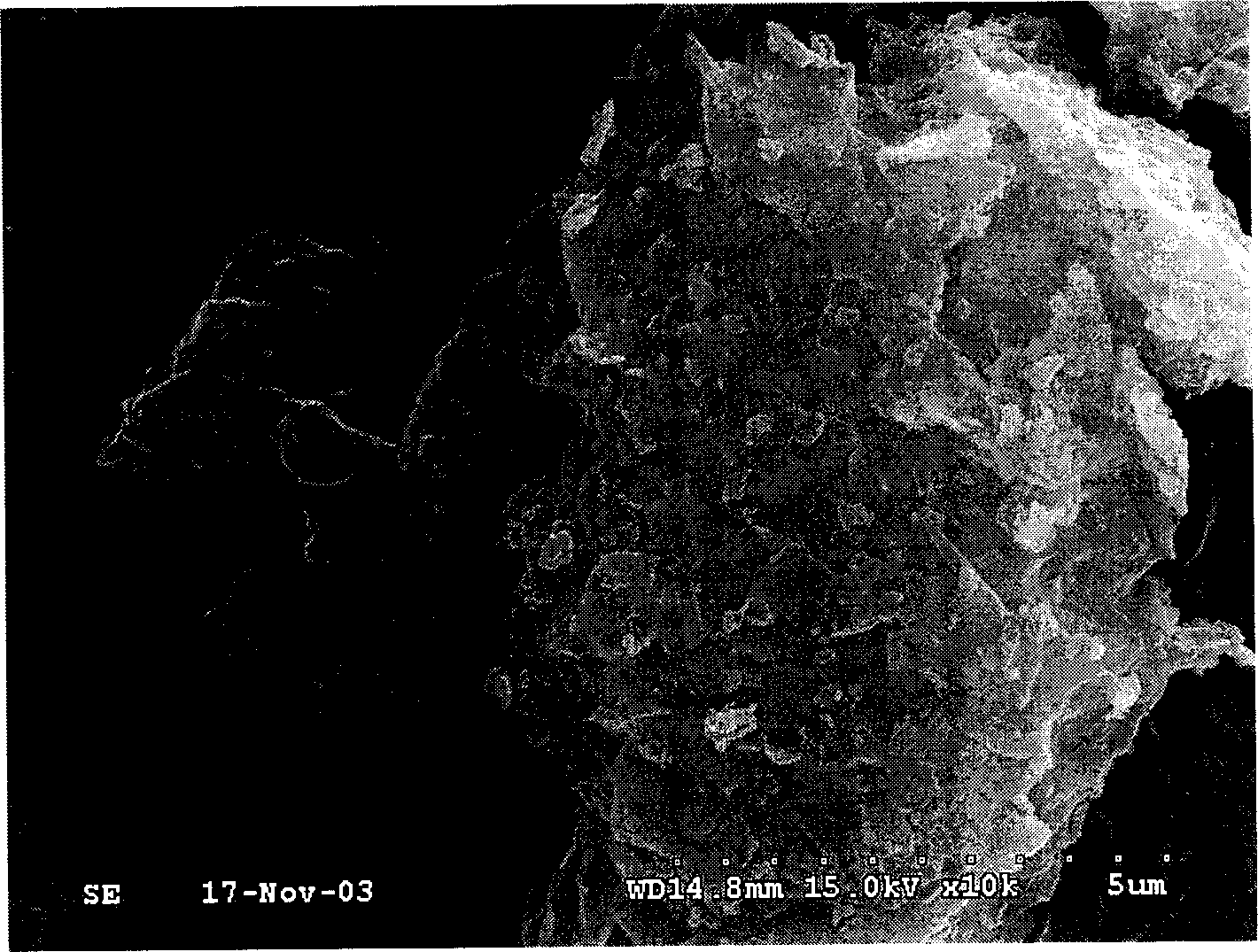

[0074] With reference to the technological process of Fig. (7), in the process that NaOH implements modification, add 5kgNaF simultaneously as modification auxiliary agent, other operating methods are with embodiment 1, and gained final product is 330kg. The field emission scanning picture of the modified bentonite is shown in Figure (6), and other results are listed in Table 1.

Embodiment 3

[0076] With reference to the technological process of Fig. (7), carry out modification through NaOH, adjust pH to 9.0 with 10% (wt%) oxalic acid solution and 5% (wt%) sodium dihydrogen phosphate, and maintain 30 minutes and be no more than 9.0 ± 0.5 After the range, add 1kgN(CH 2 COOH) 3 And average molecular weight is the commodity polyvinylpyrrolidone (PVP) of 44000~54000, and other operation is with embodiment 1, obtains final product 330kg. The product test results are listed in Table 1.

[0077] test

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com