Full optical fibre circular phase converter and its processing method

A processing method and all-fiber technology, applied in instruments, optics, nonlinear optics, etc., can solve the problems of small second-order nonlinearity, impossible, and difficult to realize optical fiber, and achieve small scattering and loss, simple processing, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

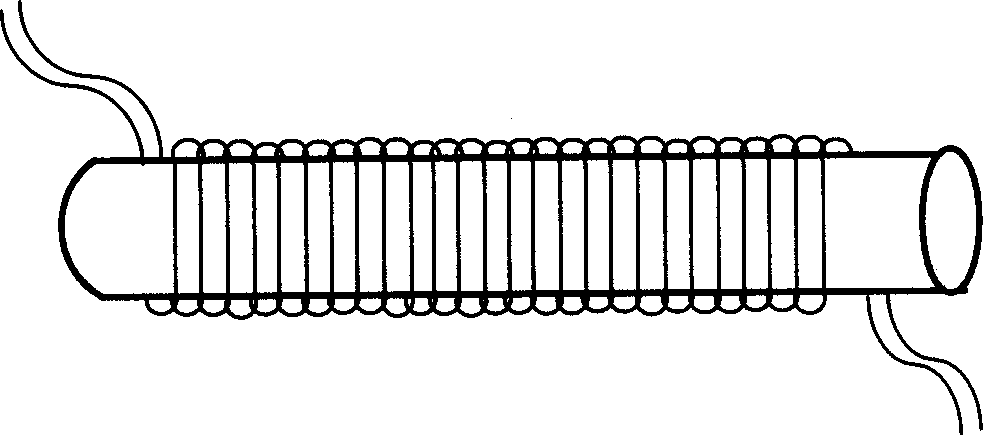

[0025] Such as figure 1 As shown, the present invention first coats the electrode on the outer surface of the insulating cylindrical rod, coats the epoxy resin on the outer surface of the electrode rod, and directly winds the optical fiber on the electrode rod, corrodes the outer cladding of the optical fiber, and then coats the outer surface of the optical fiber Electrodes are plated on the surface, and high voltage and high temperature are applied between the two electrodes to polarize the optical fiber.

[0026] The processing procedure of the present invention is divided into two major steps, and the first step is to make the optical fiber ring, plate the electrode, specifically as follows:

[0027] 1) Choose a cylindrical rod of insulating material with a length of 3-4cm and a diameter of 2-3cm, preferably ceramic. The surface of the cylindrical rod is ground and polished, and then evenly plated with a layer of electrodes (internal electrodes) to form an electrode rod, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com