Double-layered bionic pseudo-structure of cervical intervertebral disci, and its mfg. process

A cervical intervertebral disc and manufacturing process technology, applied in the field of manufacturing engineering, can solve problems such as single structure and inability to simulate the outer fibrous ring of cervical intervertebral disc, and achieve the effect of good shape memory function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

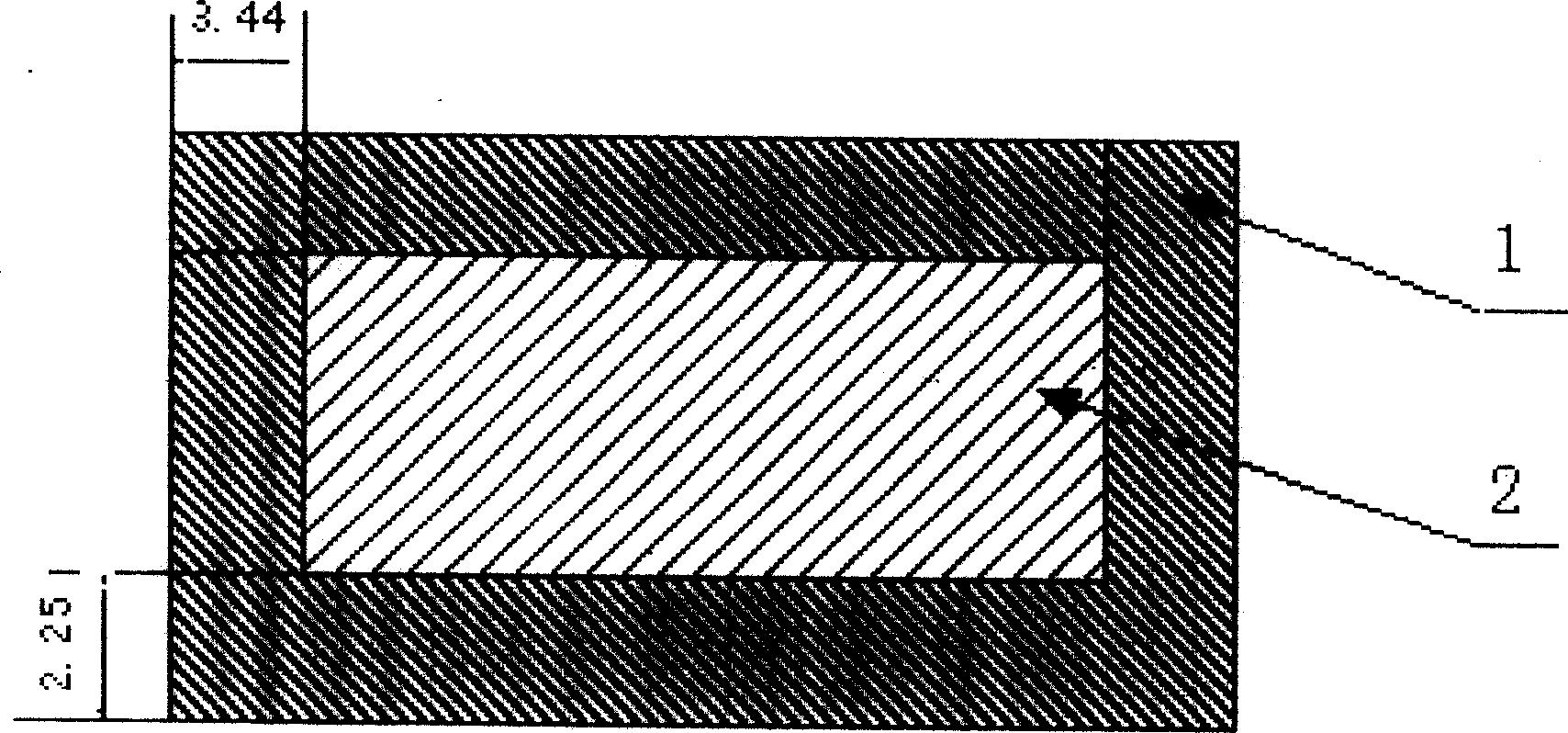

[0009] Example 1: see figure 1 , 2, the present invention firstly adopts CAD to construct human intervertebral disc prototype, the model of nucleus pulposus prosthesis 2 and the model of annulus prosthesis 1 are all designed to be cylindrical, adopts rapid prototyping to obtain the mold of annulus prosthesis 1 and nucleus pulposus prosthesis The mold of body 2, and make the centroid of the mold of nucleus pulposus prosthesis 2 and the centroid of the mold of annulus prosthesis 1 coincide, the base of the mold of nucleus pulposus prosthesis 2 and the bottom of the mold of annulus fibrosus 1 The edge distance is 2.25mm, and the cylindrical diameter difference between the mold of the fibrous annulus prosthesis 1 and the mold of the nucleus pulposus prosthesis 2 is 6.88mm; add polyvinyl alcohol powder into boiling water with a mass ratio of 2:10, and place it in a boiling water bath Stir until the polyvinyl alcohol is completely dissolved to obtain a polyvinyl alcohol aqueous solu...

Embodiment 2

[0010] Embodiment 2: Firstly, CAD is used to build a human intervertebral disc prototype, the models of the nucleus pulposus prosthesis 2 and the annulus prosthesis 1 are designed to be cylindrical, and rapid prototyping is used to obtain the mold of the annulus prosthesis 1 and the nucleus pulposus prosthesis 2, and make the centroid of the mold of the nucleus prosthesis 2 coincide with the centroid of the mold of the annulus prosthesis 1, the base of the mold of the nucleus prosthesis 2 and the base of the mold of the annulus prosthesis 1 The distance is 2.25mm, and the cylindrical diameter difference between the mold of fibrous annulus prosthesis 1 and the mold of nucleus pulposus prosthesis 2 is 6.88mm; add polyvinyl alcohol powder into boiling water with a mass ratio of 2.3:10, and stir in a boiling water bath Until the polyvinyl alcohol is completely dissolved to obtain a polyvinyl alcohol aqueous solution; inject the polyvinyl alcohol aqueous solution into the mold of th...

Embodiment 3

[0011] Embodiment 3: First, CAD is used to construct a human intervertebral disc prototype, the models of the nucleus pulposus prosthesis 2 and the annulus prosthesis 1 are designed to be cylindrical, and rapid prototyping is used to obtain the mold of the annulus prosthesis 1 and the nucleus pulposus prosthesis 2, and make the centroid of the mold of the nucleus prosthesis 2 coincide with the centroid of the mold of the annulus prosthesis 1, the base of the mold of the nucleus prosthesis 2 and the base of the mold of the annulus prosthesis 1 The distance is 2.25mm, and the cylindrical diameter difference between the mold of fibrous annulus prosthesis 1 and the mold of nucleus pulposus prosthesis 2 is 6.88mm; add polyvinyl alcohol powder into boiling water with a mass ratio of 2.1:10, and stir in a boiling water bath Until the polyvinyl alcohol is completely dissolved to obtain a polyvinyl alcohol aqueous solution; inject the polyvinyl alcohol aqueous solution into the mold of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive modulus | aaaaa | aaaaa |

| Compressive modulus | aaaaa | aaaaa |

| Compressive modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com