Substrate processor

A substrate processing device and technology for substrates, which are applied in the fields of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of processing liquid recovery, residual processing liquid, and uneven drying of substrates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

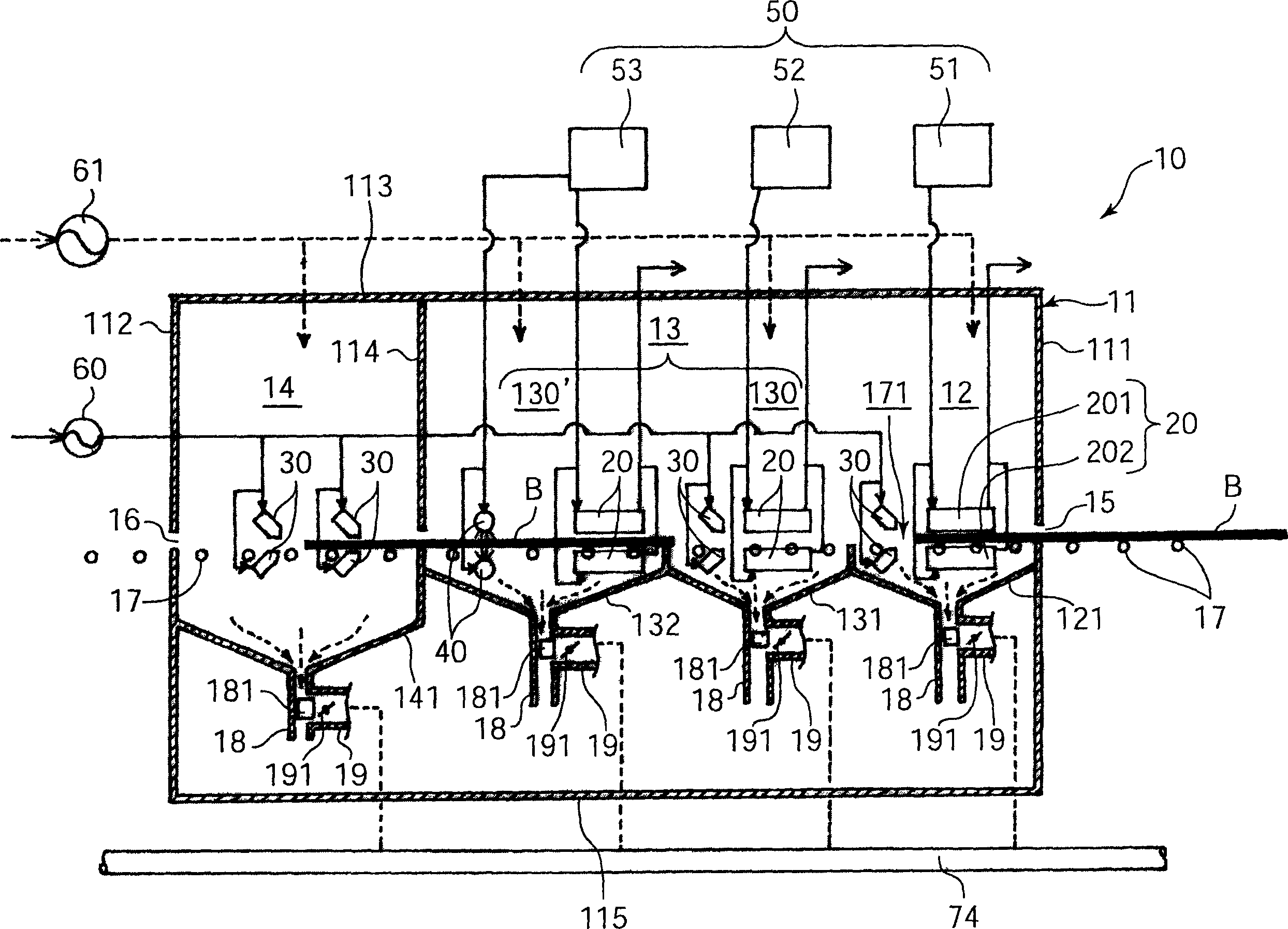

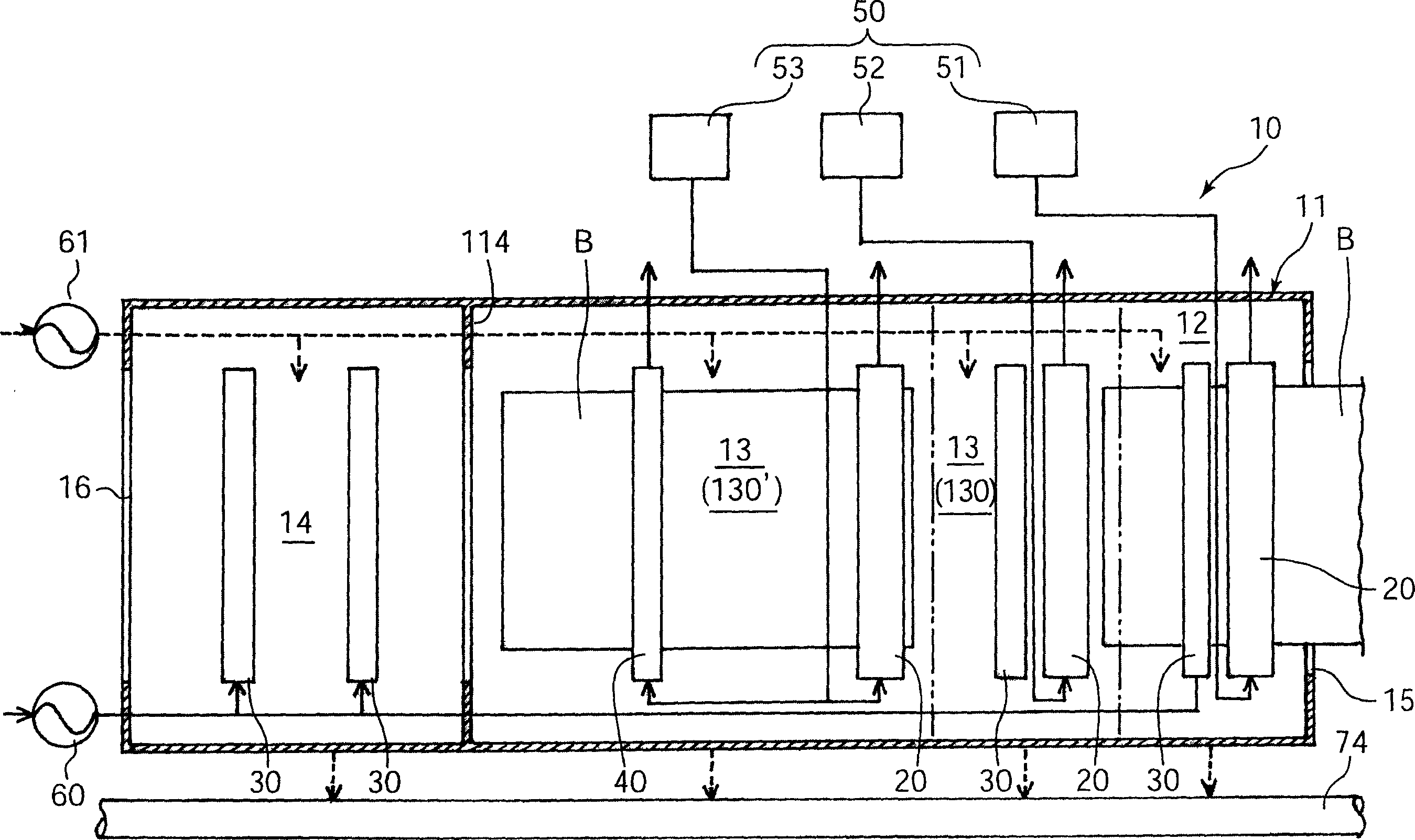

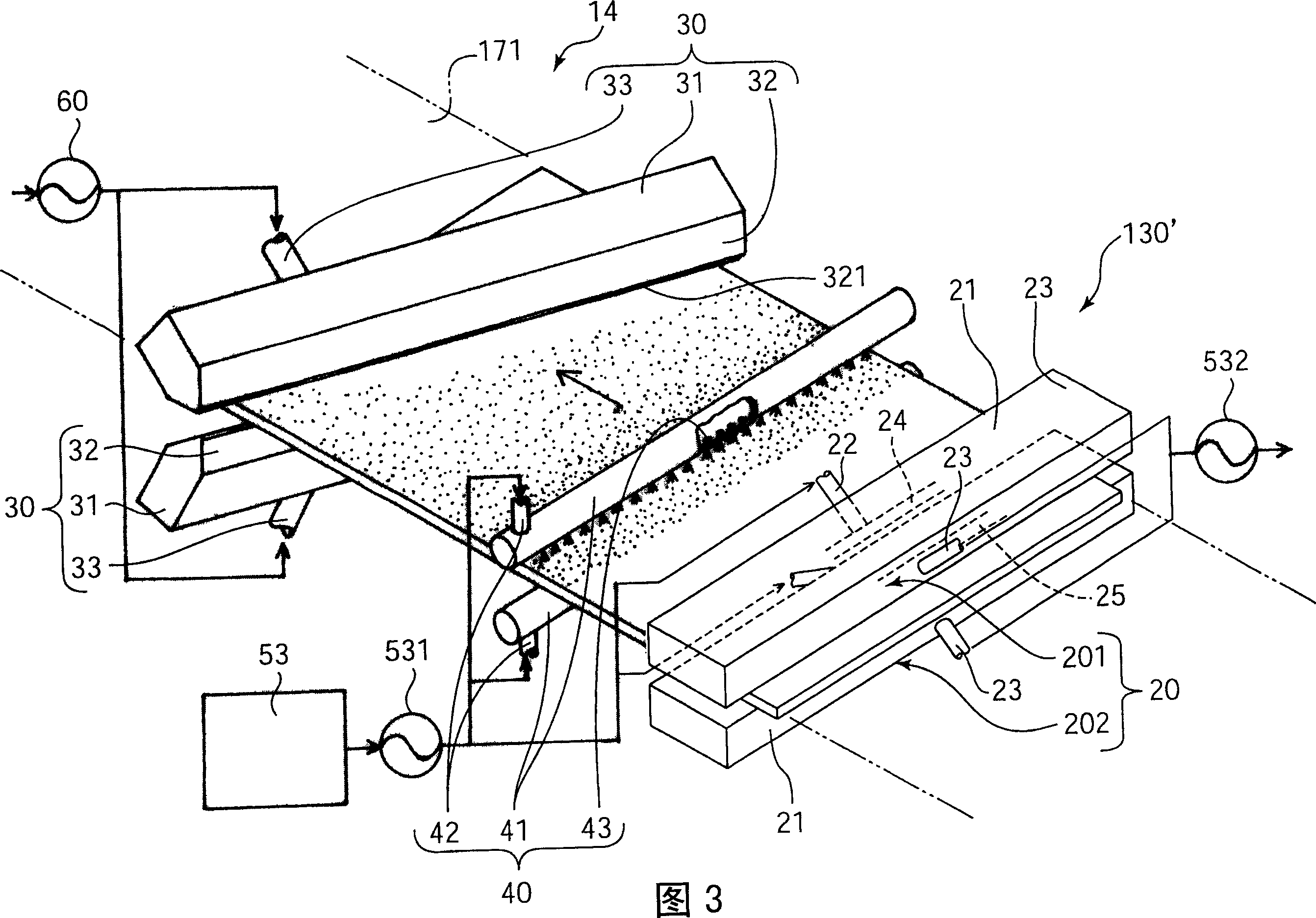

[0031] figure 1 The substrate processing apparatus 10 shown in one embodiment of the present invention is an etching processing apparatus for etching a substrate, such as figure 1 As shown, inside the rectangular parallelepiped housing 11, there is an etching section 12 for etching the substrate B, and a cleaning section 13 for cleaning the substrate B sent out from the etching section 12. 13 Send out the substrate B to the drying section 14 for drying treatment.

[0032] On the upstream side wall 111 ( figure 1 On the right side of ), a substrate delivery port 15 is opened, and a substrate delivery port 16 is opened on the downstream side wall 112 at a position opposite to the aforementioned substrate delivery port 15 . In addition, between the substrate delivery port 15 and the substrate delivery port 16, along the substrate transport direction ( figure 1 A plurality of transport rollers 17 are provided in parallel at equal intervals, and a transport path 171 for transpor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com