Prestress mixed beam with concrete plate and corrugate steel web beam

A technology of corrugated steel webs and concrete slabs, applied in bridges, bridge materials, bridge construction, etc., can solve problems such as height restrictions of steel beams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

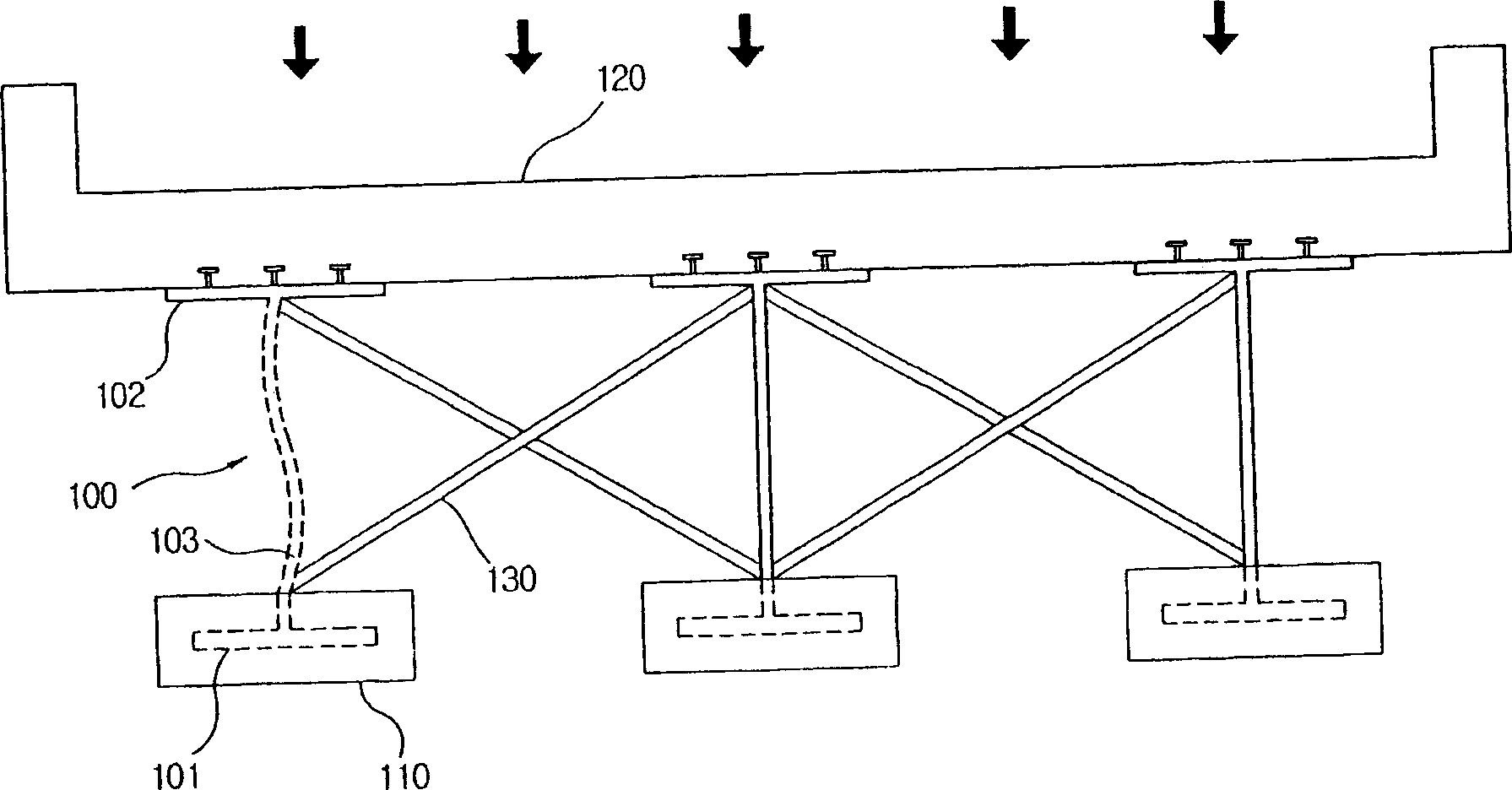

[0015] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

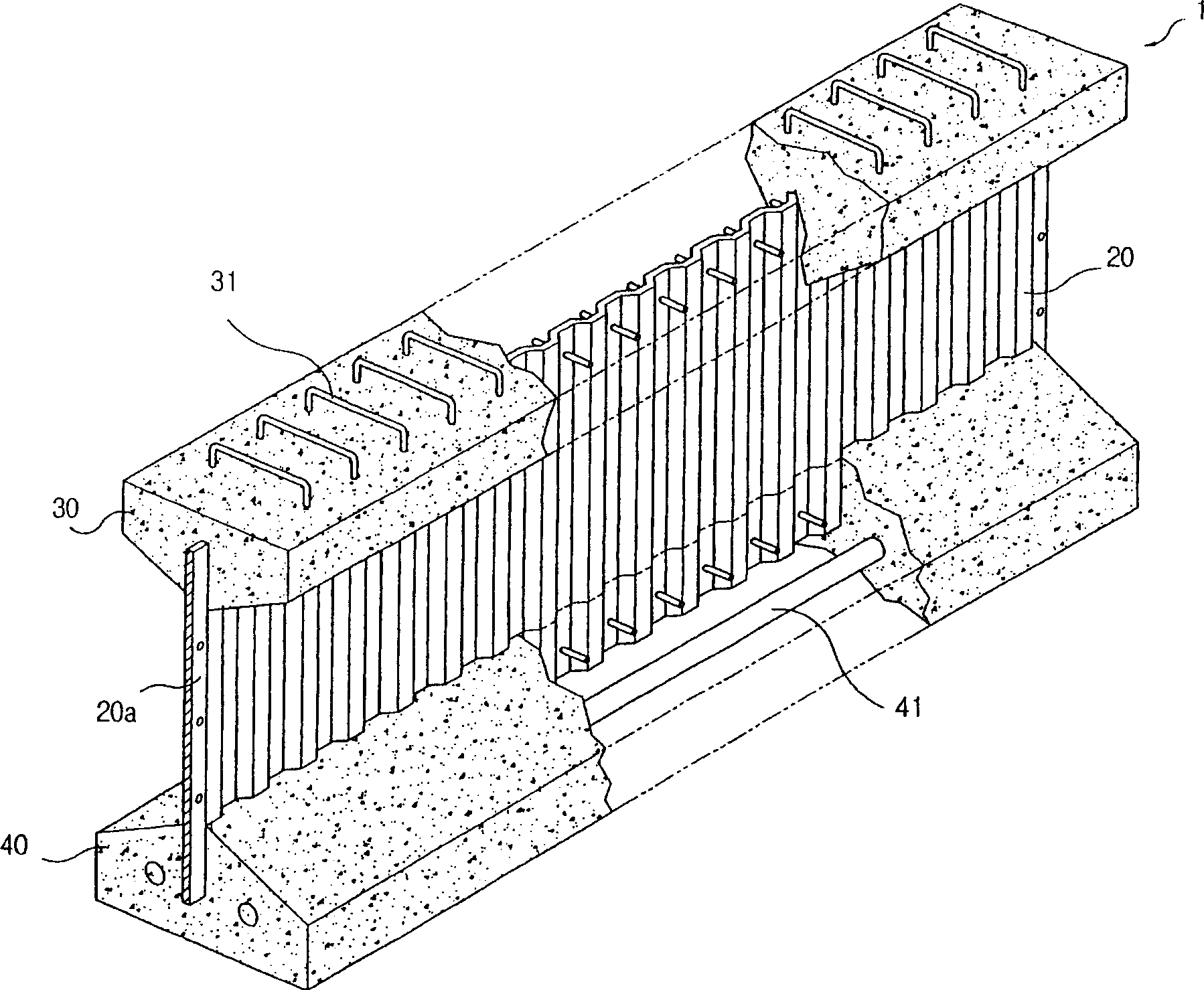

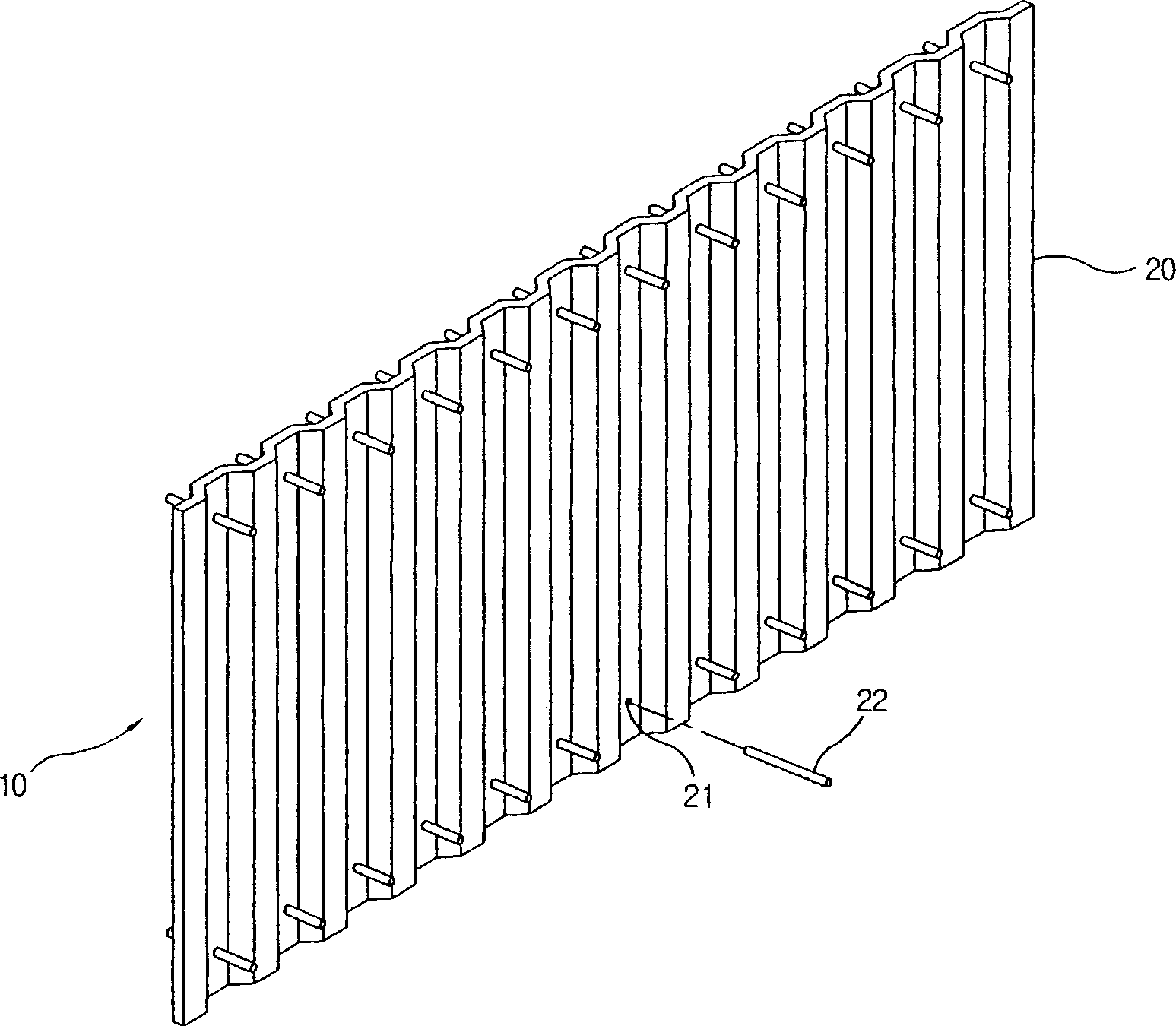

[0016] figure 2 is a perspective view schematically showing a sub-composite beam in which a web corrugated steel beam is bonded to a concrete slab, according to a preferred embodiment of the invention, and image 3 is a perspective view which is schematically represented for figure 2 Steel beams in hybrid beams.

[0017] Such as figure 2 and 3 As shown in , a composite beam 1 according to a preferred embodiment of the present invention includes a steel beam 10 and concrete slabs 30 and 40 integrally combining the steel beam 10 at upper and lower sides of the steel beam 10 . Steel beam 10 is made of corrugated steel plate 20 with uniform vertical corrugated pleats, rather than flat steel plate.

[0018] Such as image 3 As shown in , the steel plate forming the web of the steel girder 10 in the present invention is made of corrug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com