High-temperature superconductive and permanent magnet microgyrorotor with stabilized hung

A permanent magnet rotor and high-temperature superconducting technology, applied to rotating gyroscopes, etc., can solve problems such as limited application range, difficulty in assembly and debugging, and difficulty in cost reduction, and achieve the effects of expanding application range, low power consumption, and good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Such as figure 1 As shown, the present invention comprises: liquid nitrogen Dewar 1, gyro rotor 32, gyro upper stator 33, gyro lower stator 34, liquid nitrogen Dewar cover 7, liquid nitrogen 8, gyro upper casing 9, gyro lower casing 16, Gyro support column 17. The connection method is as follows: the liquid nitrogen Dewar cover 7 is set on the liquid nitrogen Dewar 1 , and the liquid nitrogen 8 is set in the cavity surrounded by the liquid nitrogen Dewar cover 7 and the liquid nitrogen Dewar 1 . The gyro lower casing 16 is set on the liquid nitrogen Dewar 1 through the gyro support column 17 .

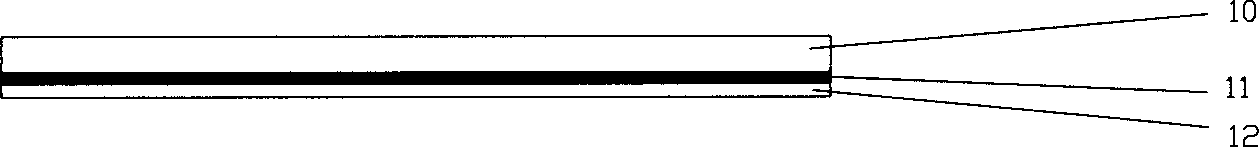

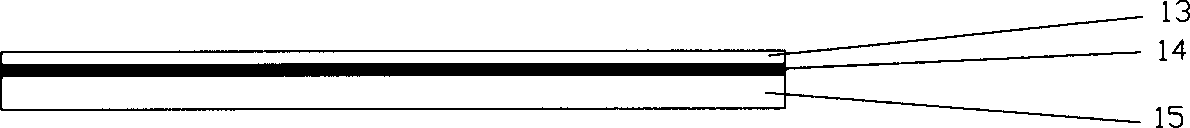

[0022] Such as Figure 4 As shown, the gyro rotor 32 is composed of a rotor driving and detecting moment adding layer 2, a cylindrical silicon nitride insulating material 3, a cylindrical permanent magnet material 4, a cylindrical silicon nitride insulating material 5, and a rotor driving and detecting moment adding layer 6. The cylindrical silicon nitride The insulating mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com