Wholly coated rail sleeper and manufacture thereof

一种包覆式、铁路轨的技术,应用在轨道、道路、涂层等方向,能够解决复合式轨枕外壳易磨损、使用寿命短、可靠性低等问题,达到保护森林、提高可靠性和使用寿命、降低维护成本的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

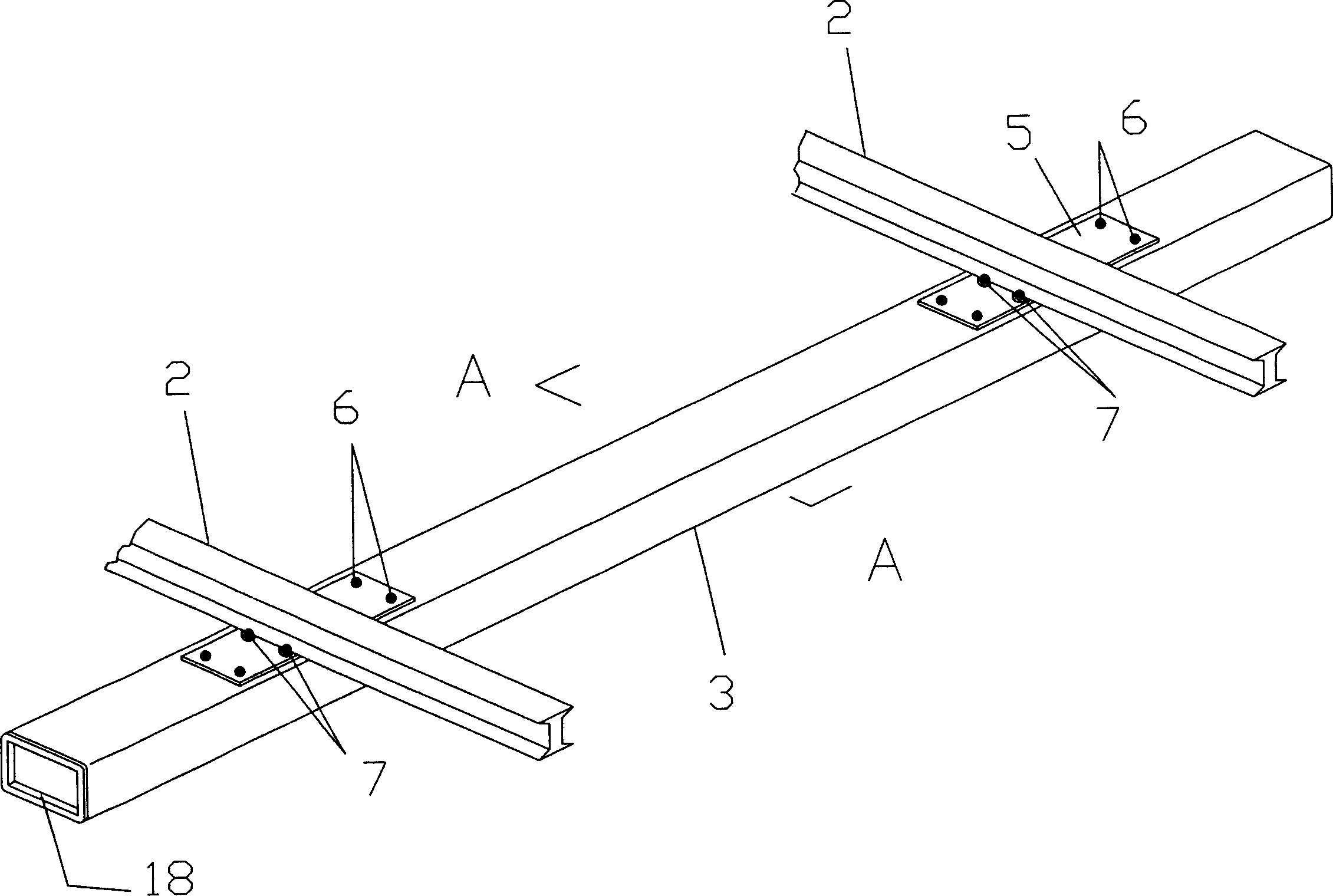

[0043] Such as figure 1 Shown: A sleeper manufactured in accordance with the principles of the present invention is shown generally at 1 and supports substantially mutually parallel railway rails 2 in a manner well known to those skilled in the art.

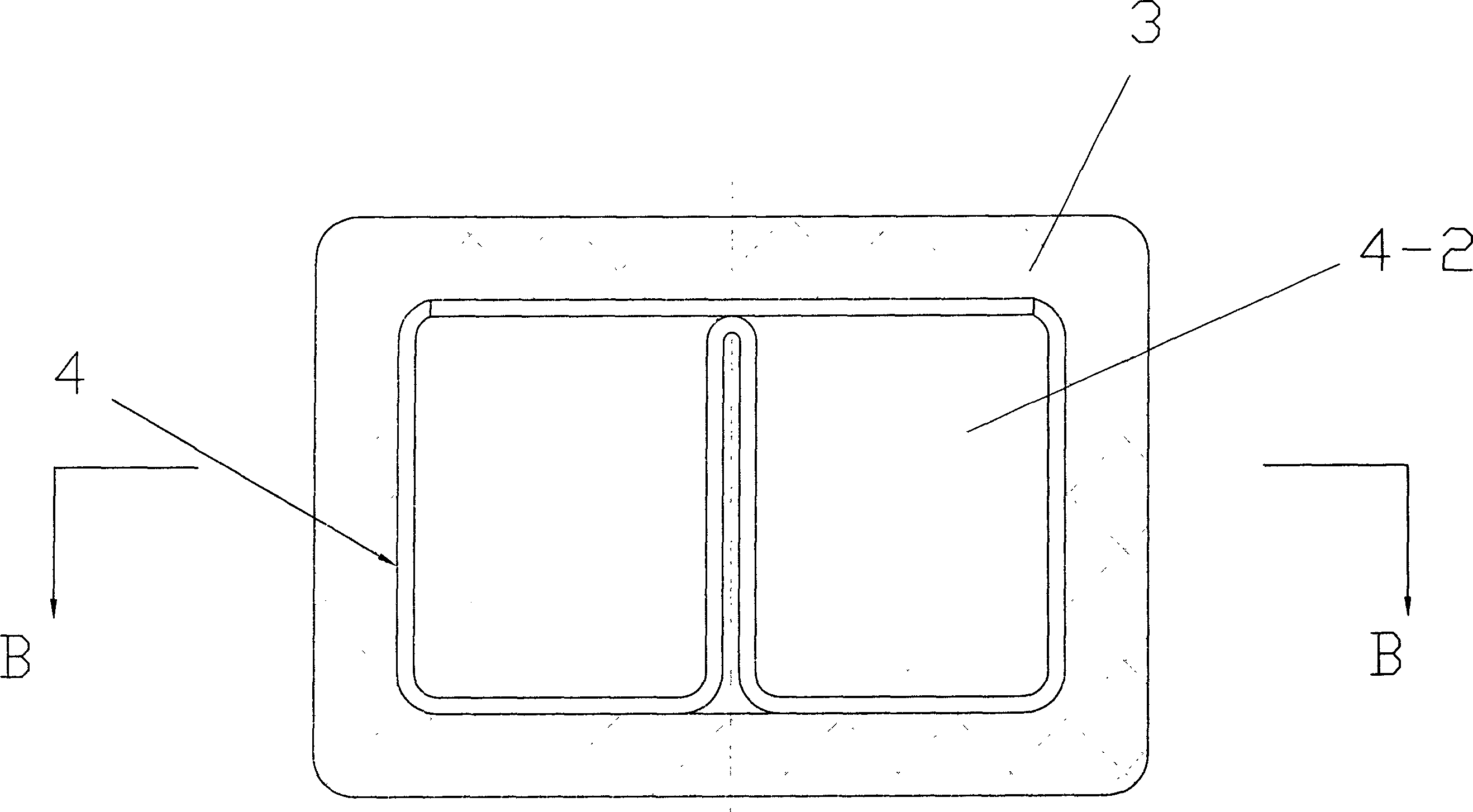

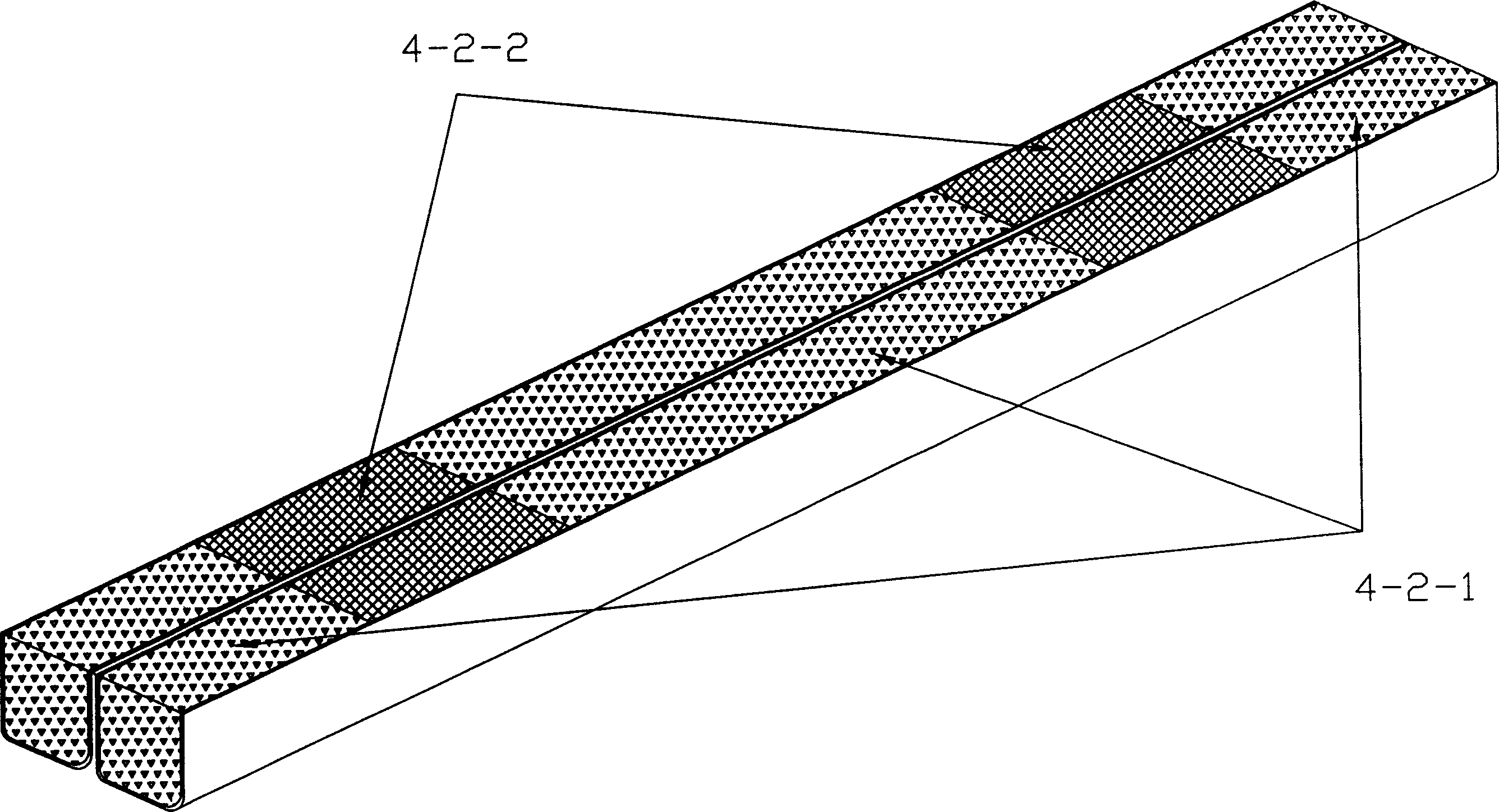

[0044] The sleeper 1 includes an outer shell shown by number 3, which is formed as a whole, and its surroundings are integrally covered on the inner core 4. During the manufacturing process, the outer shell 3 is welded and attached to the inner core 4 to form a whole, so There is no gap between the shell 3 and the inner core 4 . In this embodiment, the thickness of the shell 3 is 25.4 mm, and different thicknesses can also be selected according to needs.

[0045] The support area of the rail 2 is formed on the backing plate 5 on the surface of the shell 3, the backing plate 5 is fixed on the sleeper 1 by the fastener 6, the traditional spike 7 passes through the hole in the backing plate 5 and is nailed into the railway sleep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com