Paper folding costume fent method

A clothing and pattern paper technology, applied in the direction of sewing tools and other directions, can solve the problems of lack of uniformity, complexity, and limited popularization and application, and achieve the effects of correct and scientific distribution and positioning, low cost of use, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

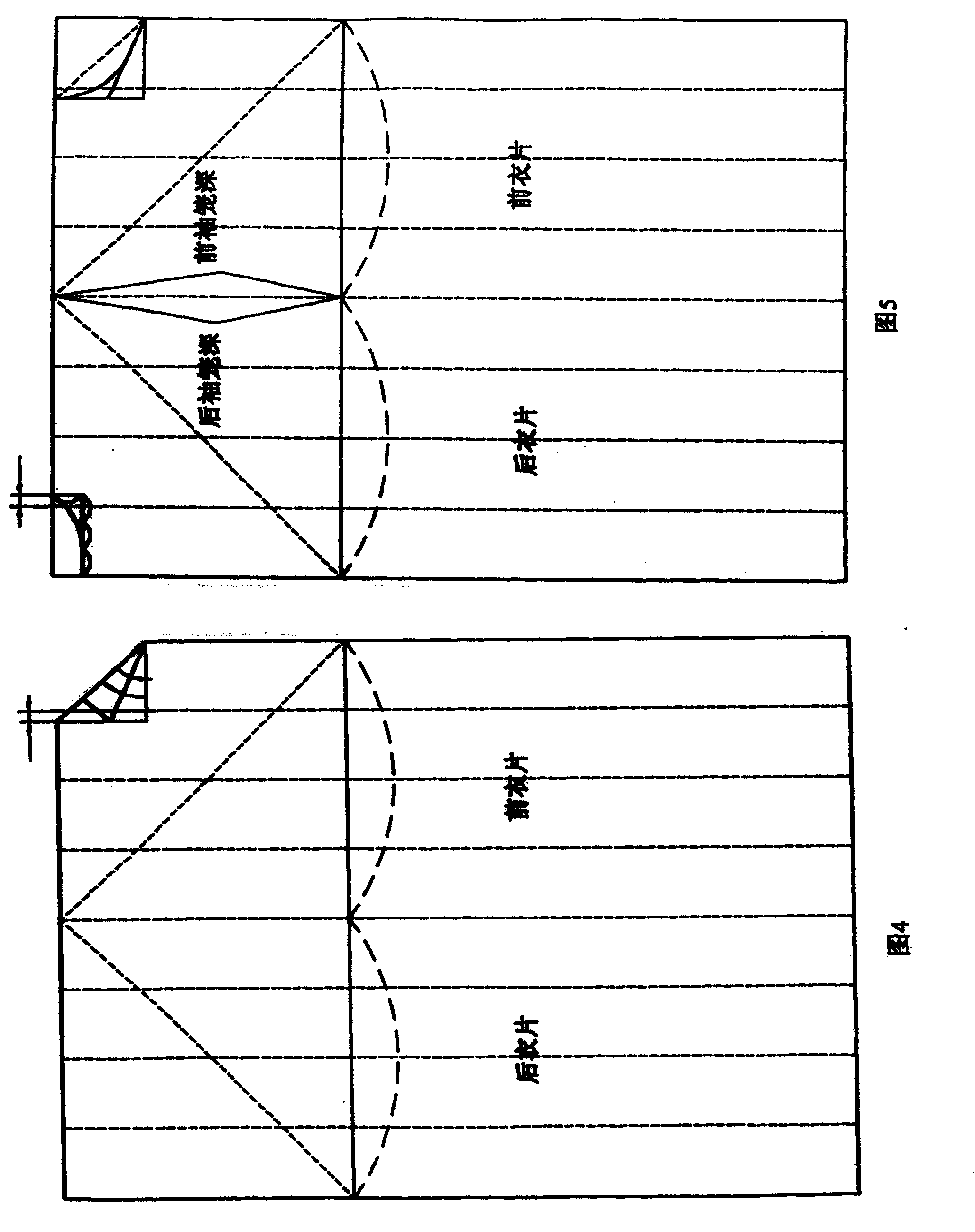

[0054] Before entering into the description of the implementation example, the schematic diagrams of the clothing line names related to cutting are shown in Figure 25 , 26 , so that everyone has a little understanding of the professional terms that may be encountered in proofing.

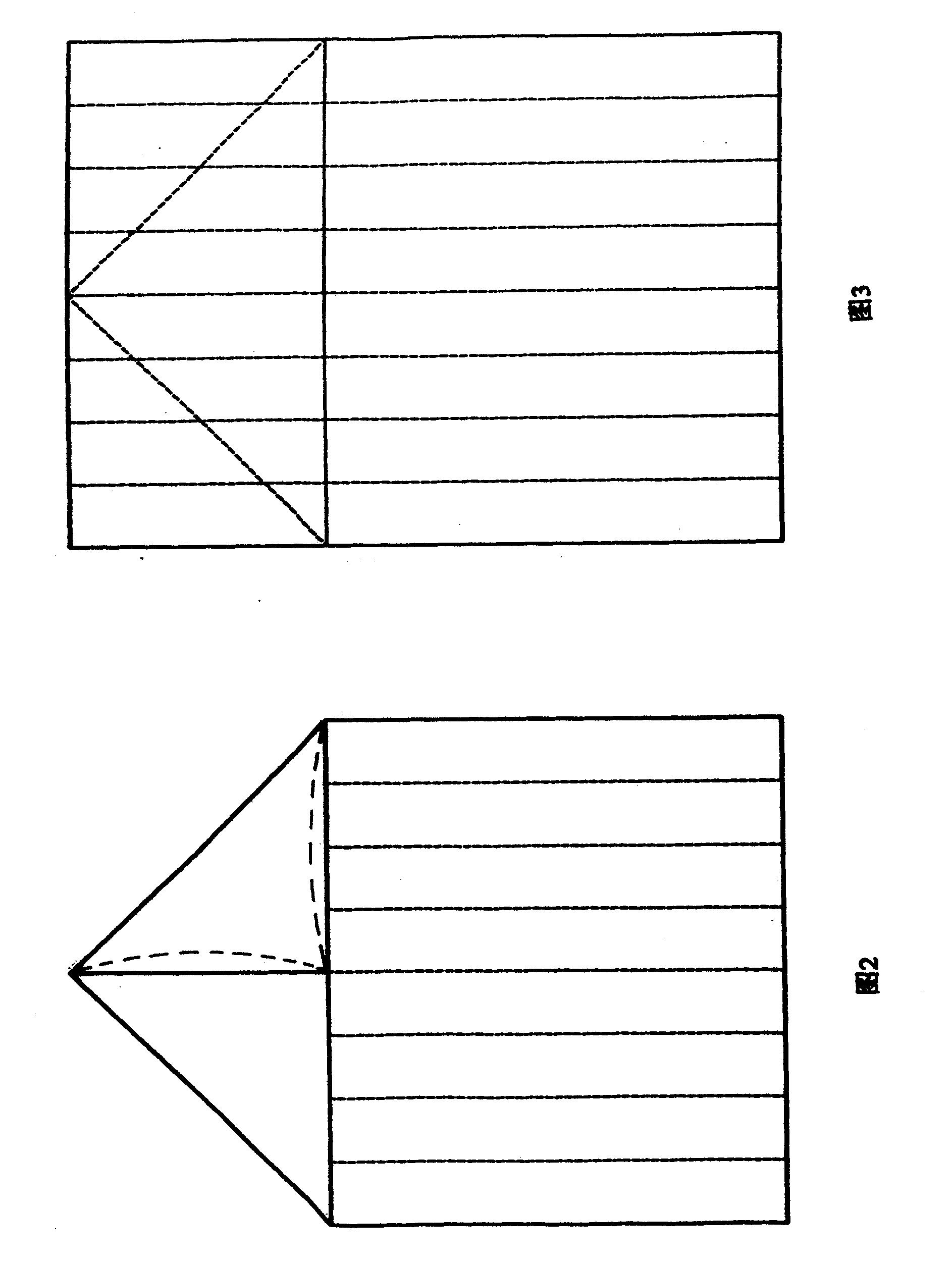

[0055] As shown in the figure, the steps related to the clothes prototype of the clothing origami proofing method of the present invention are as follows:

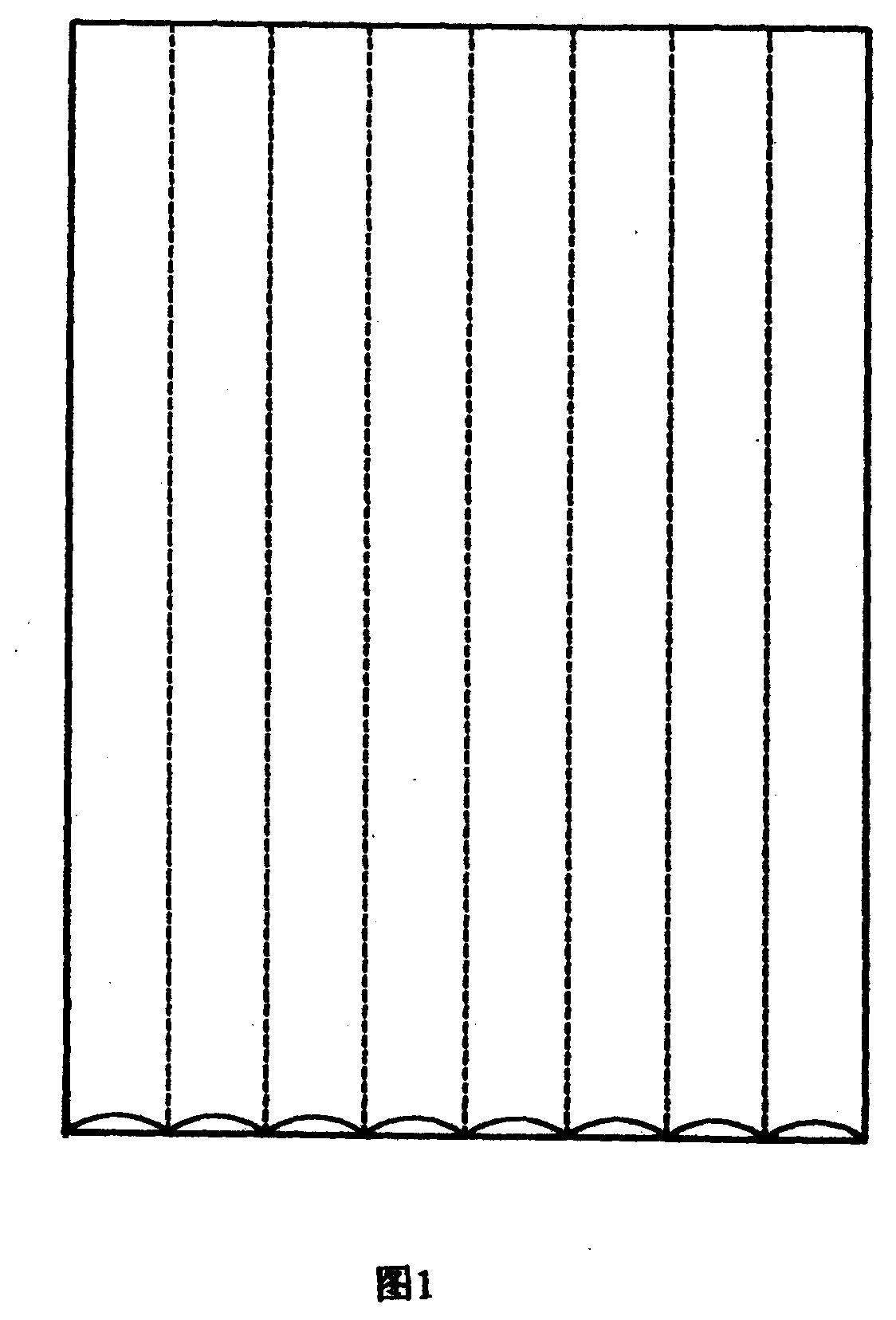

[0056] (1) Choose paper origami; choose a piece of white paper, preferably kraft paper, with a suitable size, preferably according to the pre-measured human body size such as bust size, and cut the kraft paper into a width that is 1 / 2 of the bust size of the finished garment , the length is the length of the front bodice, and then fold the kraft paper into 8 equal parts, see figure 1 hint;

[0057] (2) Fold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com