Method for making a waveguide microwave antenna

A waveguide and microwave technology, applied to antennas, waveguide horns, electrical components, etc., can solve problems that affect the production cost of antennas and limit the number of molds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

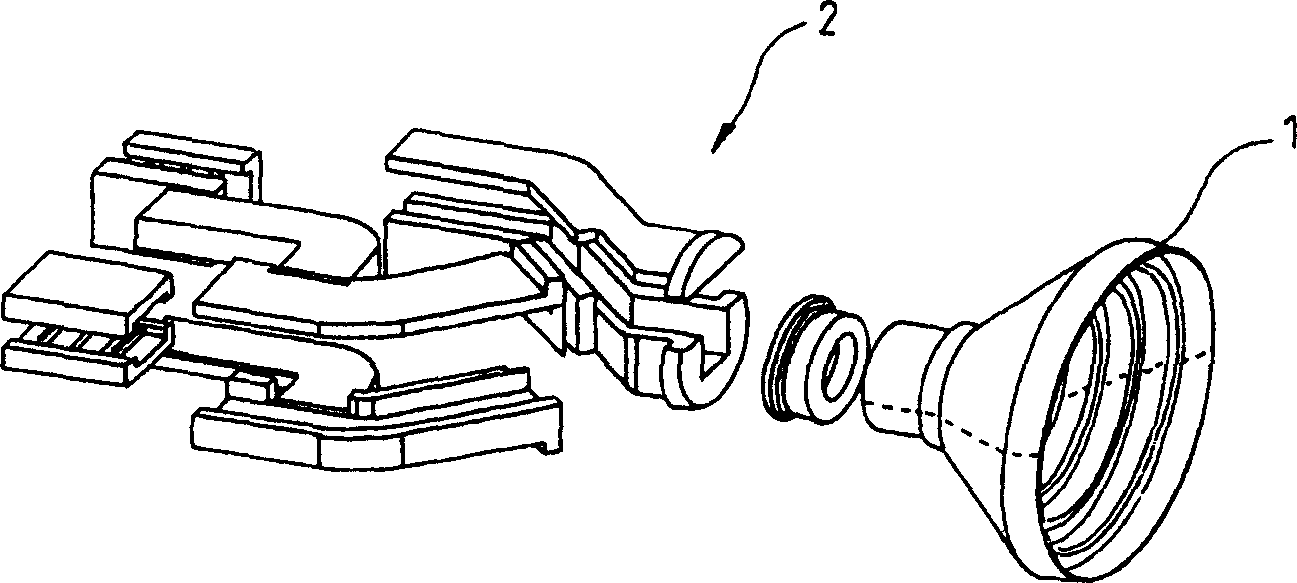

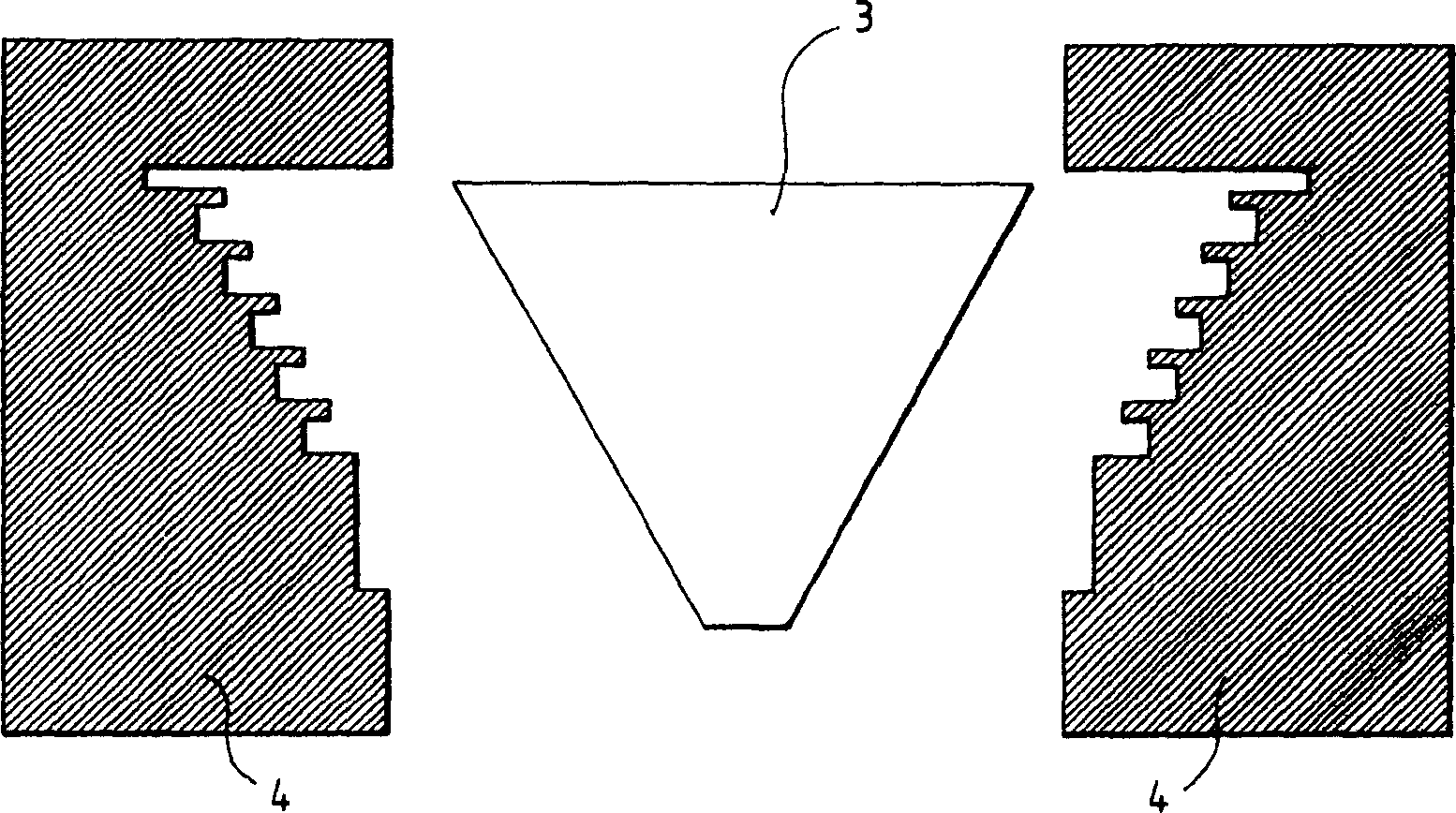

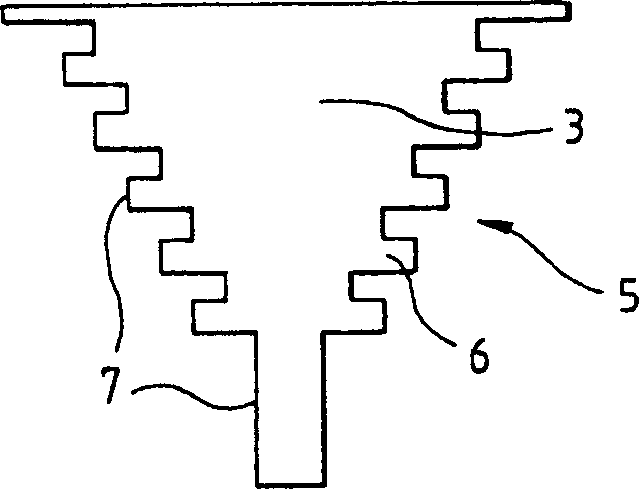

[0022] figure 2 A substantially conical preform from a block 3 of synthetic foam material is shown. The preform is made conformal in the mold 4 by hot pressing, so as to form image 3 The corrugated horn 5 is shown. Here, the synthetic foam material is a commercially available polymethacrylimide foam material named "ROHACELL HF". The bellows 6 are formed on the outer surface of the foam block 3 by thermoforming. The surface of the conformal foam block 3 is then metallized to form the corrugated horn. The thick lines on the outer surface of the foam block 3 represent the metallic coating of the foam block.

[0023] Figure 4 A substantially cylindrical preform from a block 3' of synthetic foam material is shown. The preform is made conformal in the mold 4' by hot pressing, so as to form Figure 5 The polarizer shown in 8. The conformal process consists in forming in the foam block 3' two radial grooves 9 and 10 symmetrical in the axial plane of the cylindrical foa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com