Full pneumatic combined multifunctional industrial manipulator

An industrial manipulator and combined technology, applied in the direction of manipulators, program control manipulators, manufacturing tools, etc., can solve problems such as narrow application range, potential safety hazards, unfavorable environmental cleanliness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

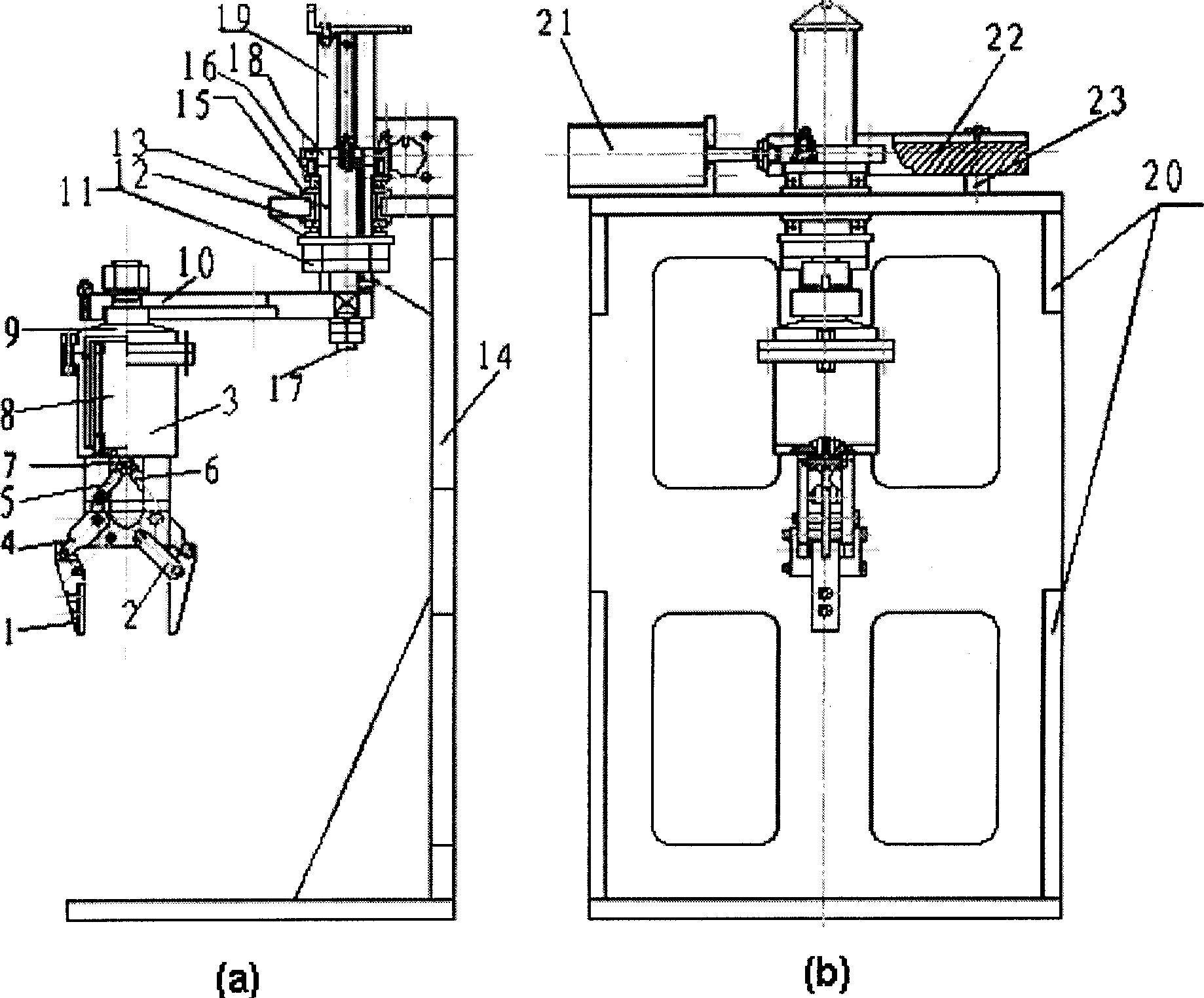

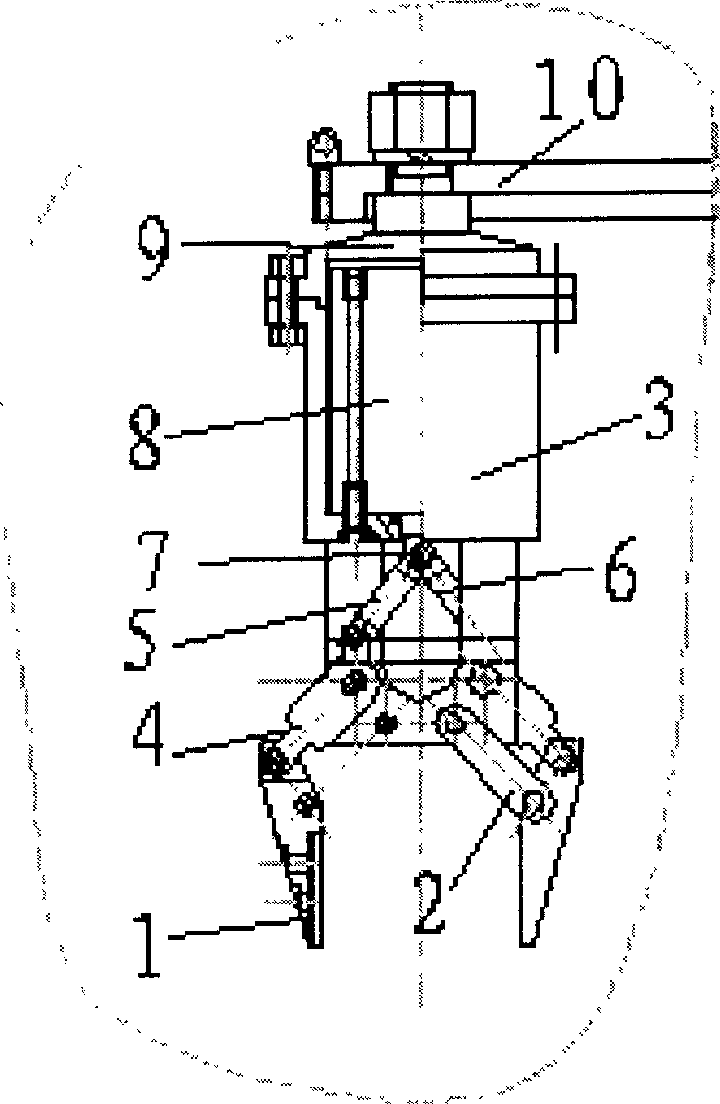

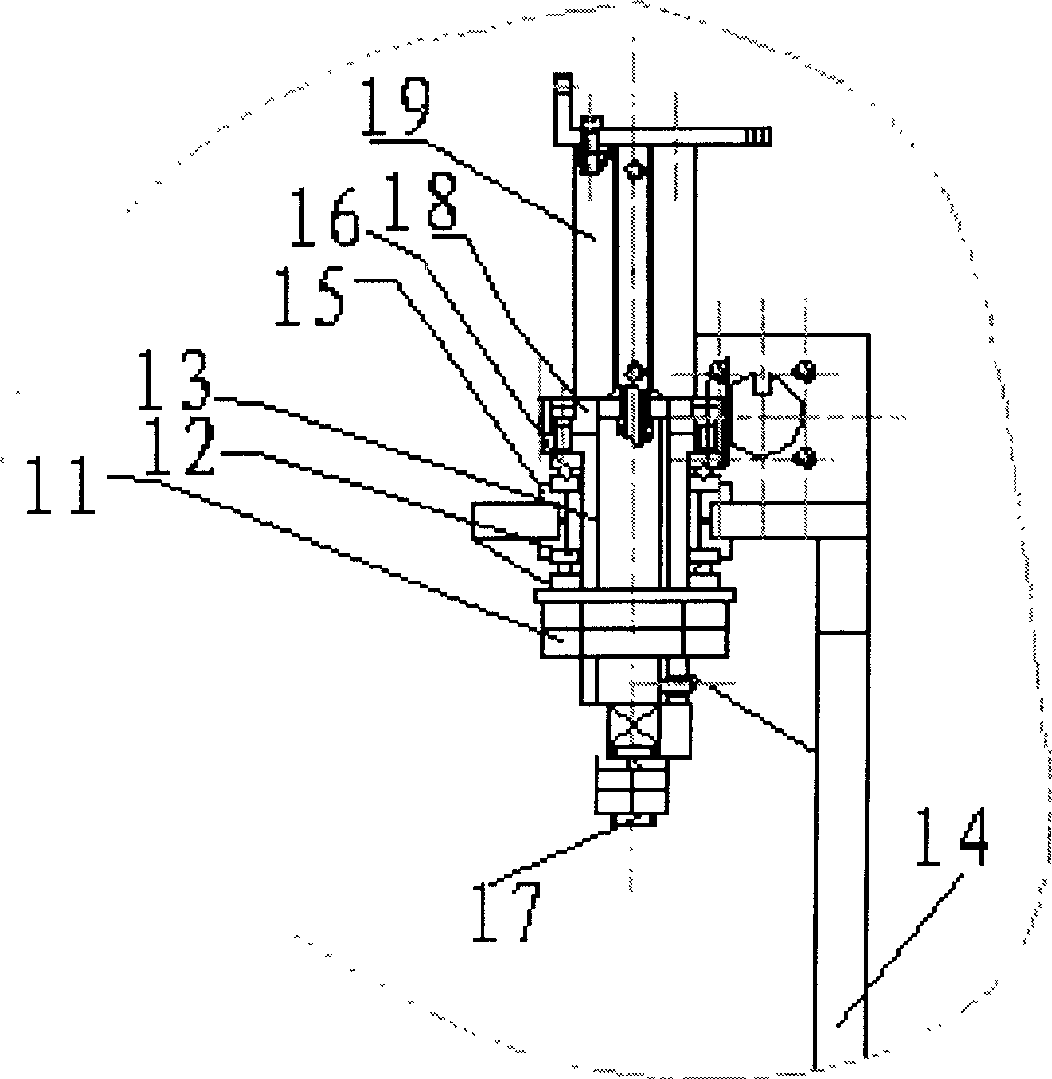

[0016] According to the above technical solution, the fully pneumatic combined multifunctional industrial manipulator of the present invention is composed of an interchangeable end effector and a pneumatic drive system. The interchangeable end effector is installed on the cantilever of a bracket for workpiece clamping. The pneumatic drive system includes air source, air source processor, two two-position three-way solenoid valves, one two-position five-way electromagnetic reversing valve, two pre-shrinking cylinders and one reciprocating cylinder, one programmable control PLC; the programmable logic controller PLC is preset with a control sequence for two pre-shrinking cylinders and a reciprocating cylinder, respectively controlling the indexing, mechanical clamping and up and down movement of the interchangeable end effector.

[0017] According to different clamping objects, the present invention designs three different end effectors, which are mechanical grippers, vacuum suct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com