Side driving rotary cultivator

A technology of rotary tiller and transmission box, applied in the field of rotary tiller, can solve the problems of unsuitable universal coupling and different output directions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

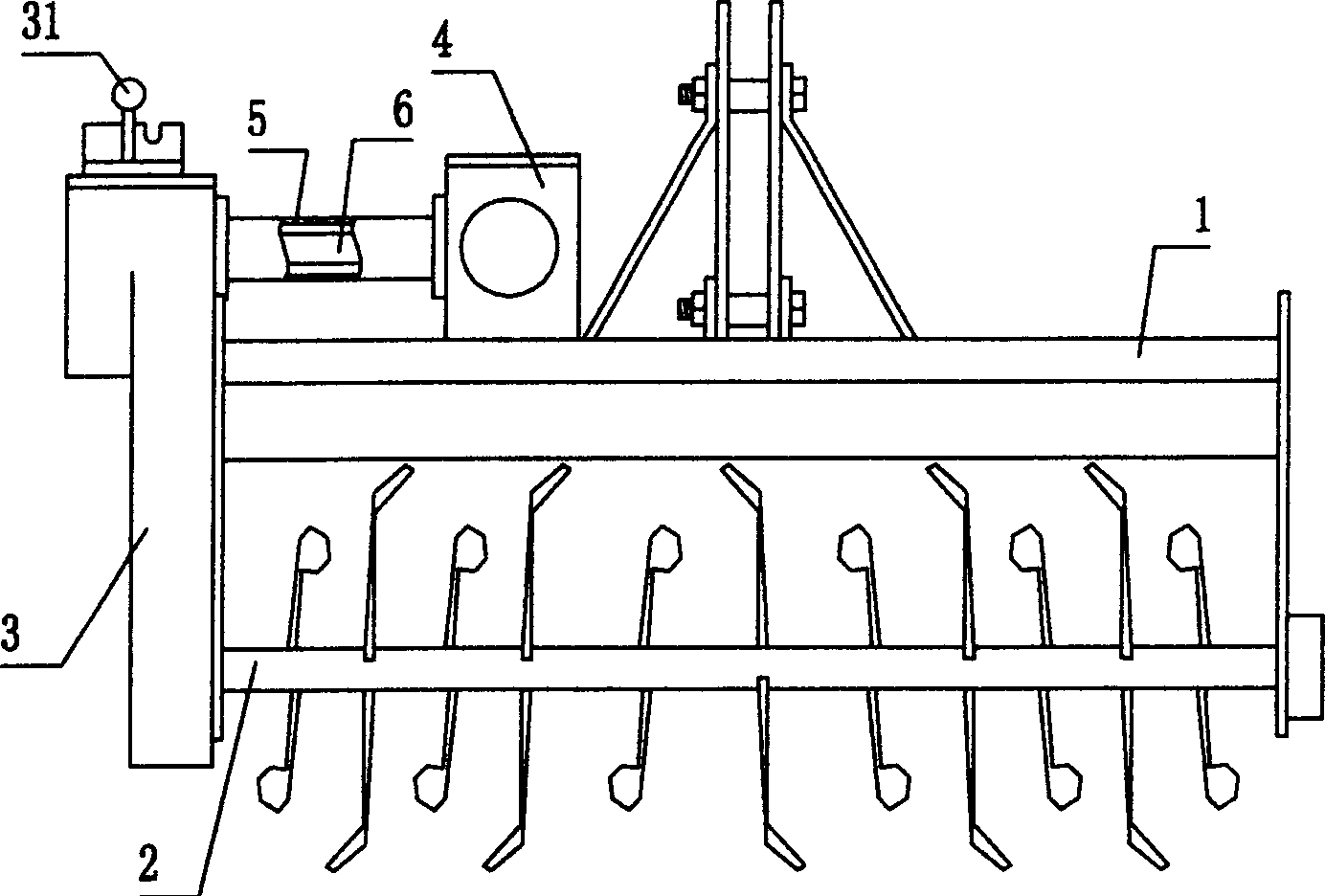

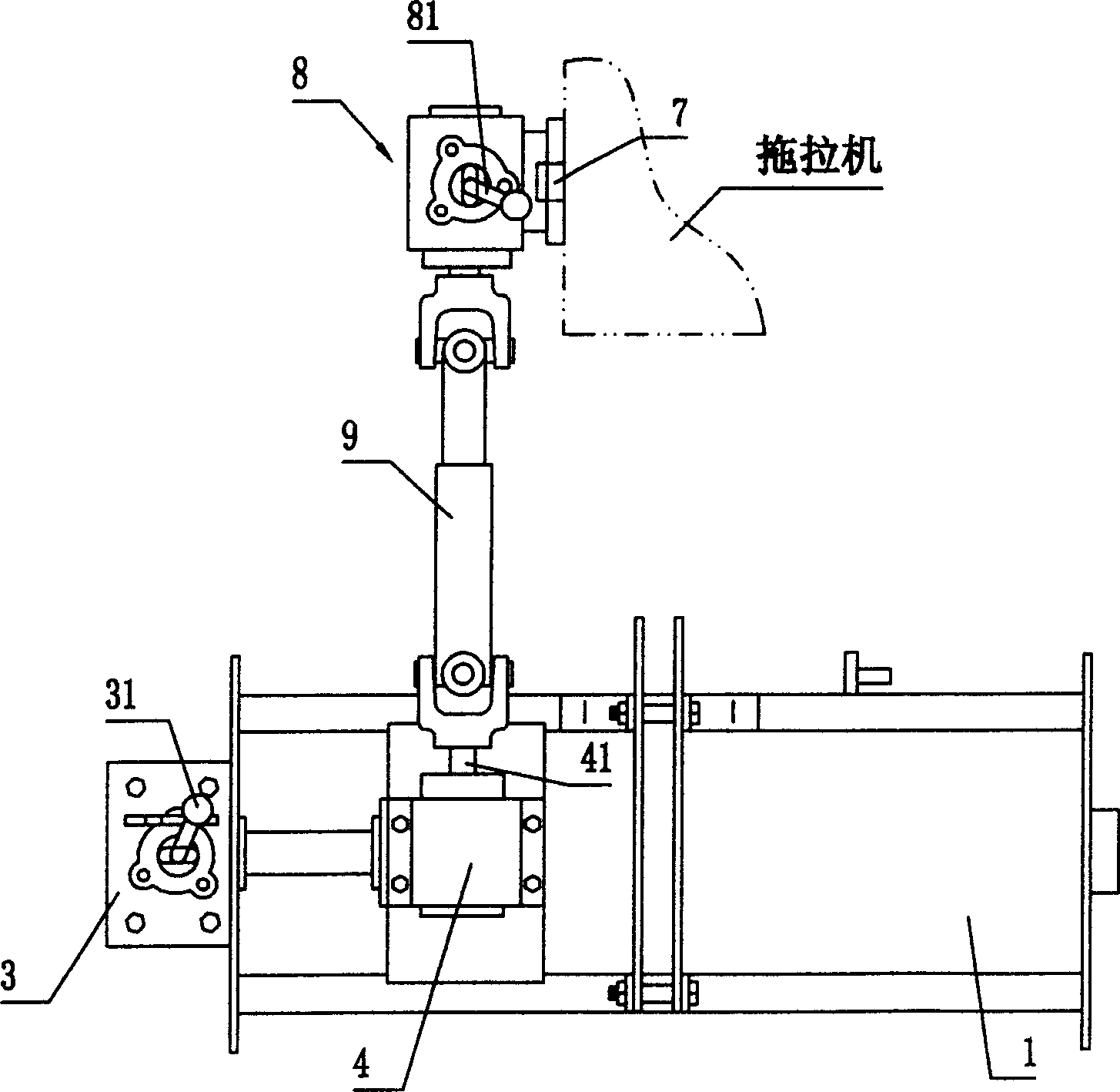

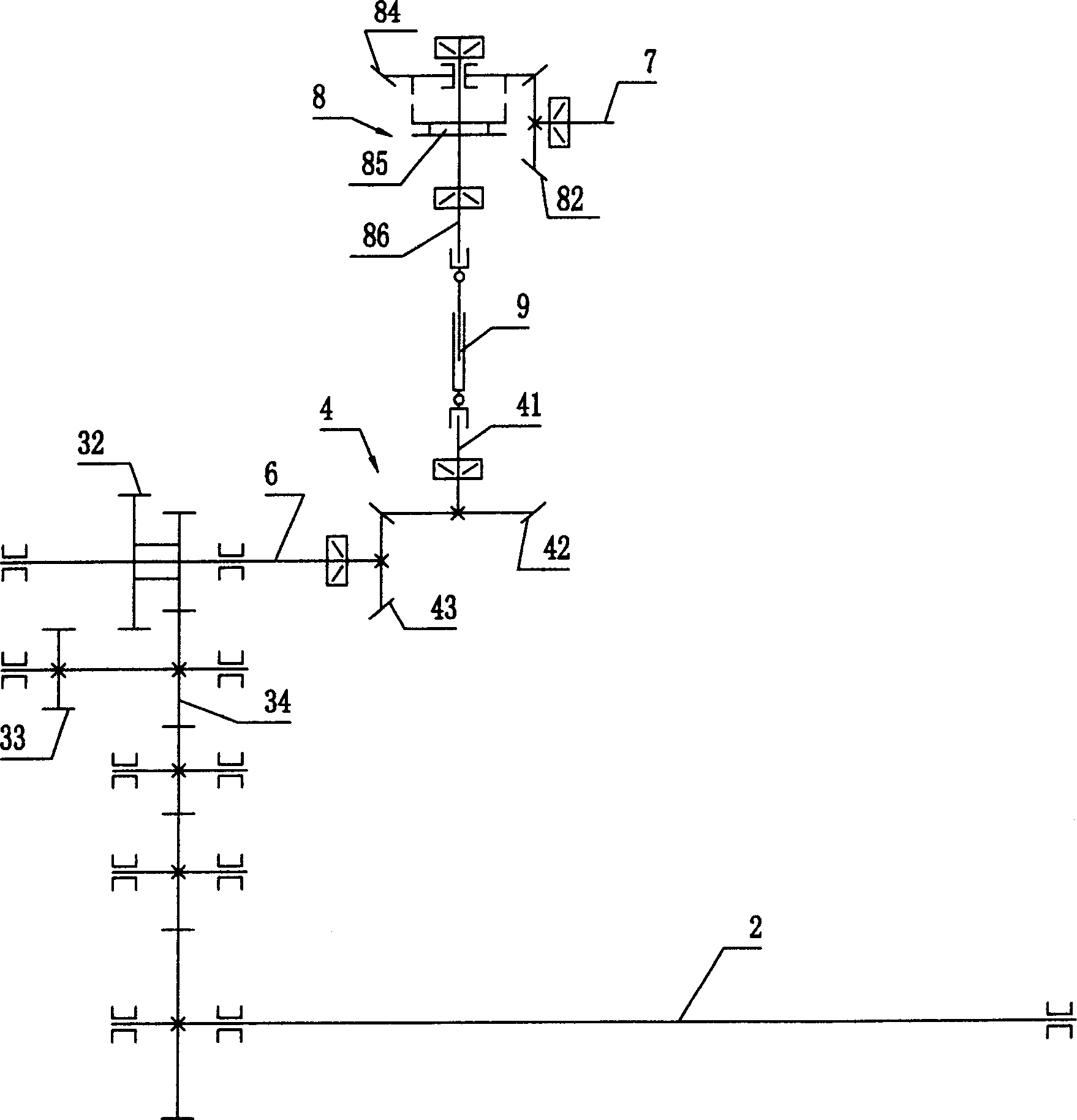

[0012] Side drive rotary tillers such as figure 1 with 2 Commonly shown, it includes a frame 1 that can be connected to the tractor by three-point suspension; the first transmission box 3 that can drive the rotary blade shaft 2 to rotate, and the first transmission box 3 is a cylindrical gearbox that can transmit power in parallel. Installed on the side of the frame 1; the second transmission box 4 is installed on the top of the frame 1, the second transmission box 4 is a bevel gear box, which can transmit power vertically, and it is offset on the side of the frame 1. Such as image 3 As shown, the second transmission box 4 includes an input shaft 41 and an output shaft, on which the third and fourth bevel gears 42 and 43 that can mesh with each other are respectively fixed, the input shaft of the first transmission box and the second transmission box The output shaft is a through shaft 6 , and a casing 5 is fixedly connected between the casing of the first transmission box ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com