Universal change-over switch

A transfer switch, a universal technology, applied in the direction of electrical components, contact drive mechanisms, etc., can solve the problems of small electrical clearance and creepage distance, complex design, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

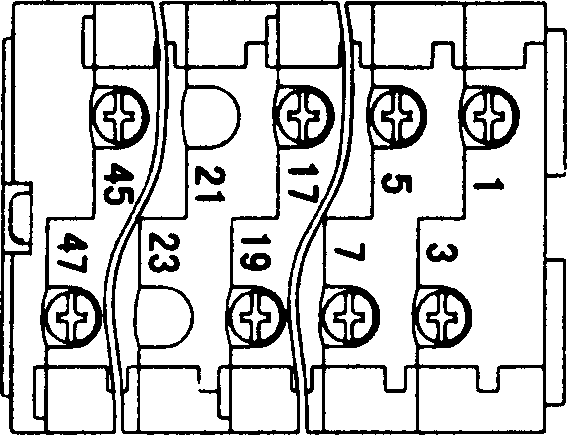

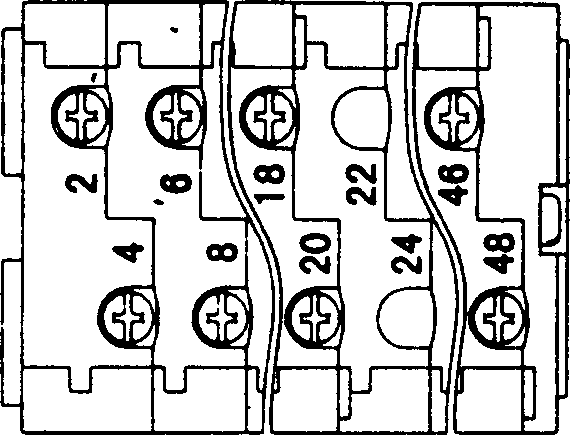

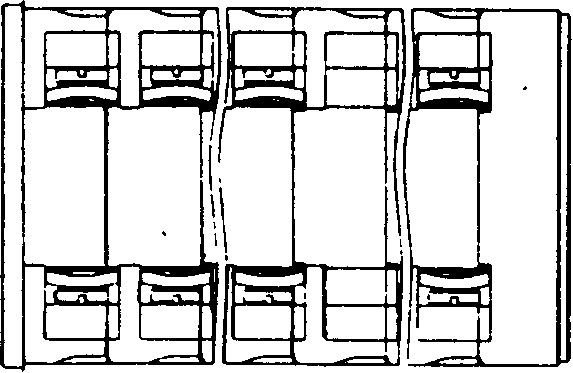

[0014] see Figure 1~3 , The universal transfer switch of the present invention is composed of a multi-layer contact assembly, an operating mechanism (not shown in the figure), and a fixing mechanism (not shown in the figure).

[0015] see Figure 4 , Each layer of the contact assembly of the universal changeover switch is composed of a base 1, electrical contacts 2, 3, a contact bracket 4, a contact spring 5, a terminal screw 6 and a cam 7.

[0016] The base 1 is axially arranged in a stepped shape, and there are two cams 7, which are arranged in parallel axially in the center of the base 1, and there are two contact brackets 4, and the two contact brackets 4 are radially stepped The top and bottom are arranged symmetrically on the inner side of the outer wall of the base 1 , the inner ends of the two contact brackets 4 respectively touch the outer edges of the two cams 7 , and a contact spring 5 is embedded between the outer ends and the inner side of the outer wall of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com