High energy electronic double action machine

A high-energy electronic and compound motor technology, applied in electrical components, electromechanical devices, etc., can solve the problems of inductive load power discount, high raw material cost, small starting torque, etc., to achieve no power harmonic interference, current waveform lag factor is small, The effect of large starting torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

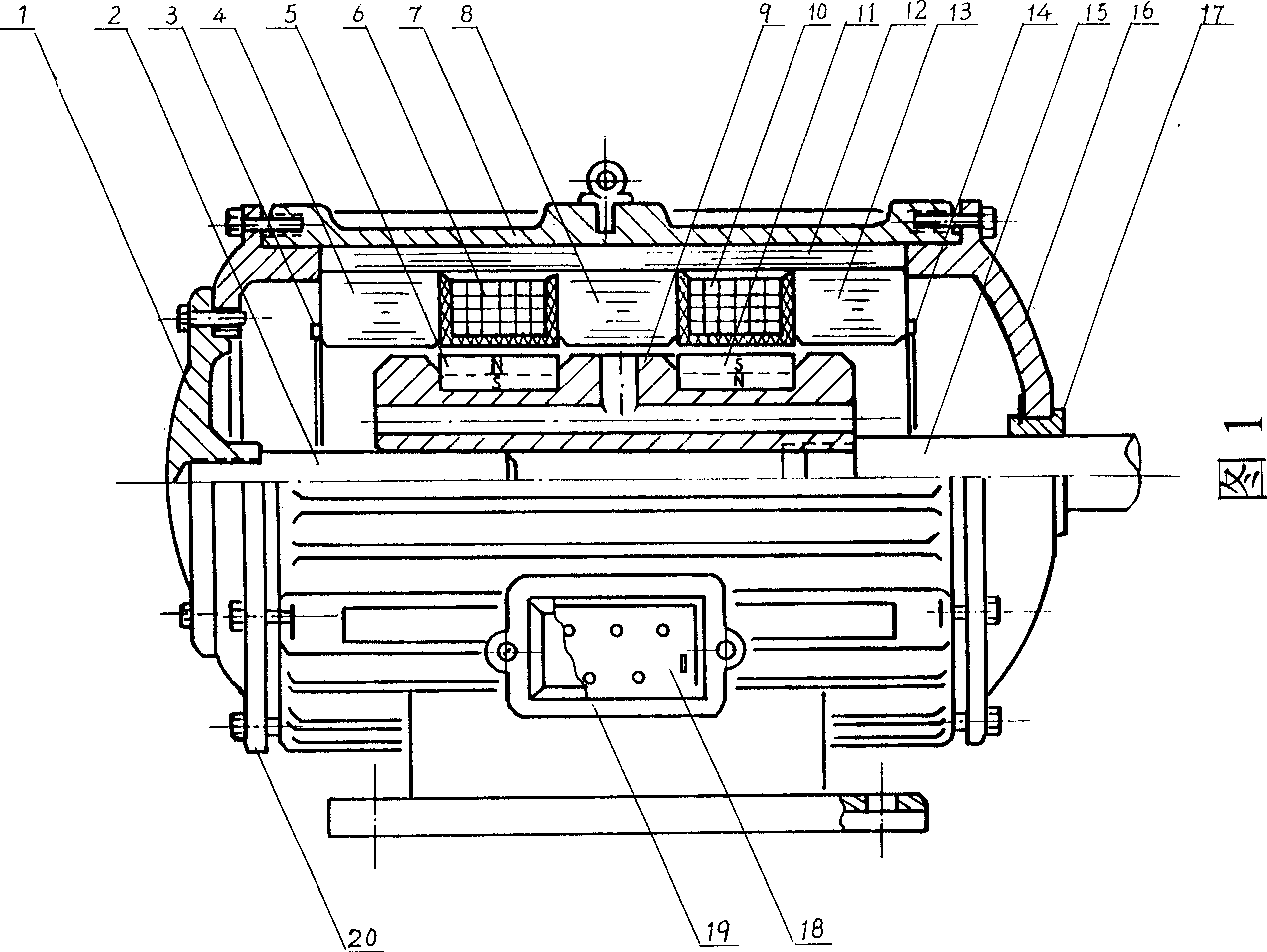

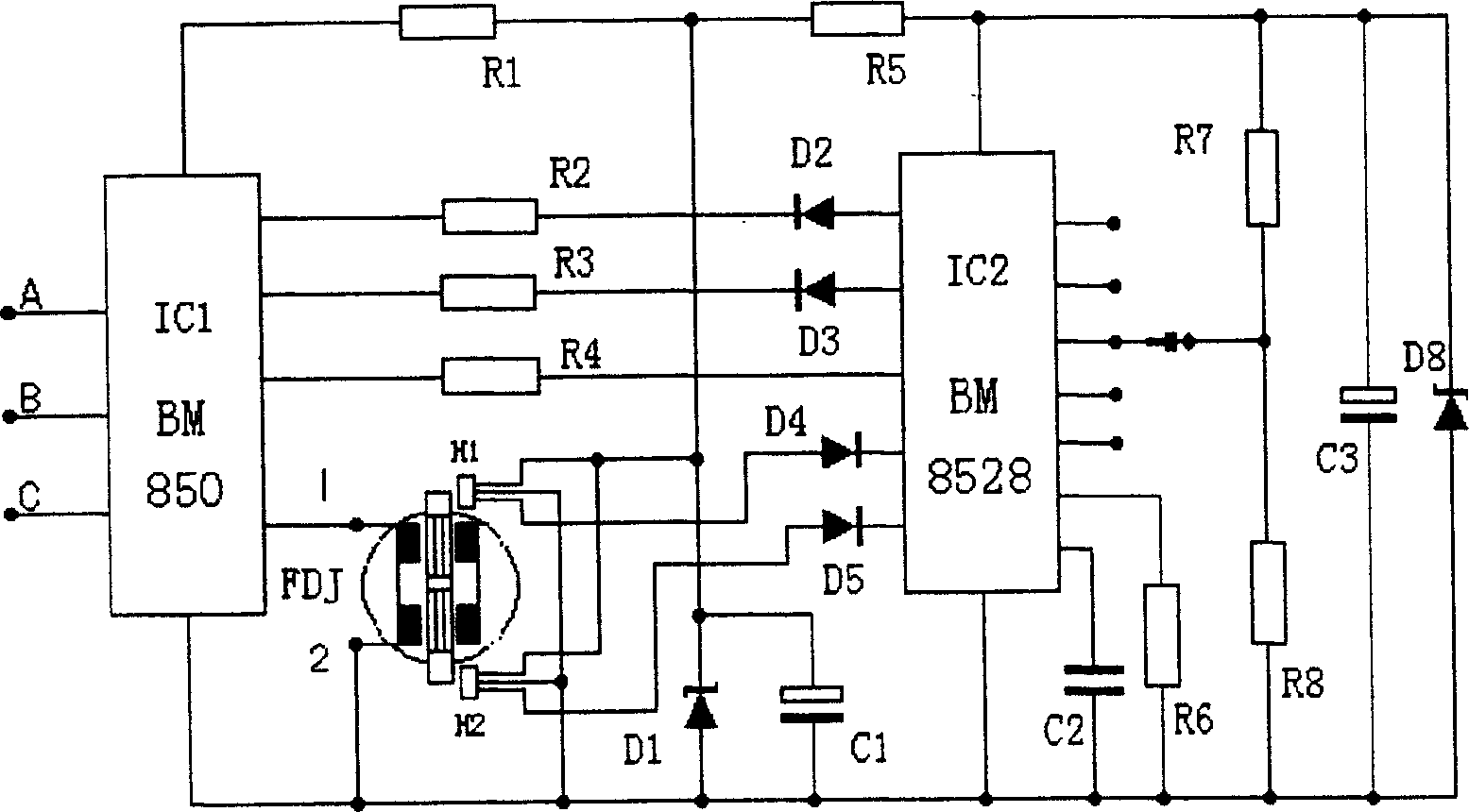

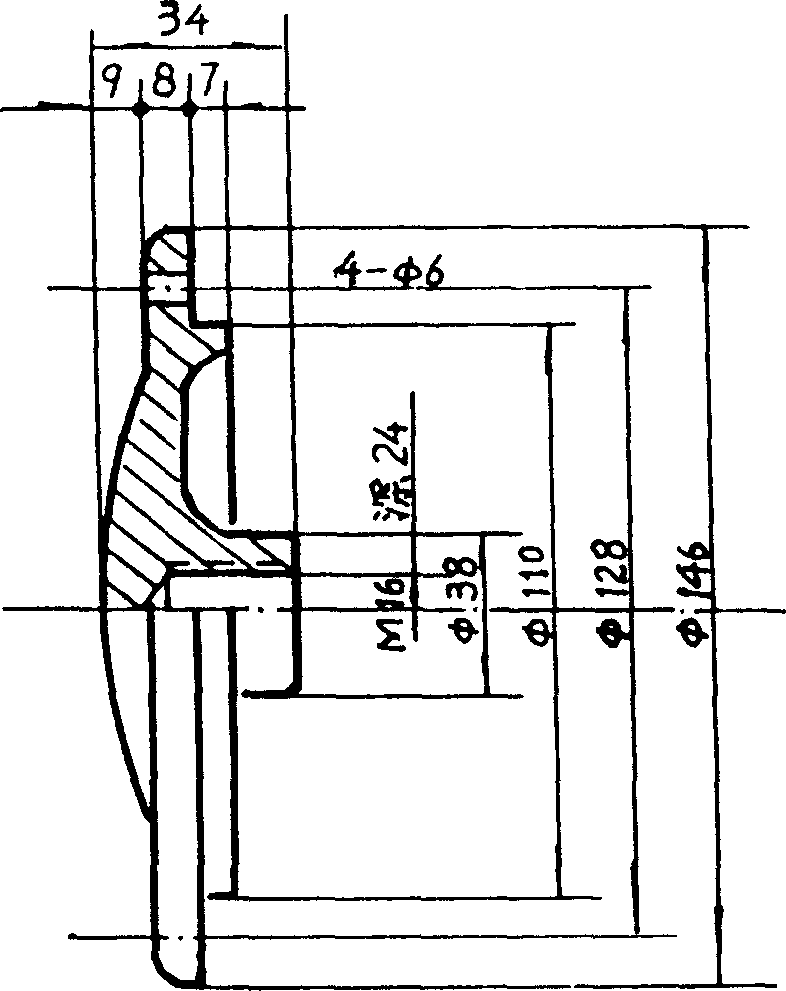

[0032] Fig. 1-16 is a kind of embodiment of high-energy electronic reciprocating machine.

[0033] Implementation: first press Figure 3-15 The requirements of the processing of each component, and according to Figure 16Custom brush circuit board. Then press Figure 1, figure 2 As shown, purchased standard parts and the following electronic components: R1 / 1K, R2 / 4.7K, R3 / 4.7K, R4 / 10K, R5 / 2K, R6 / 7.5K, R7 / 3K, R8 / 5.1K, R9 / 10K, R10 / 10K; C1 / 100 microfarad 25V, C2 / 0.01 microfarad / 63V, C3 / 100 / 16V; D1 / 24V / regulator, D2-5 / 1N4007, D6 / 12V regulator, H1 , H2 / magnetic control device, IC1 / BM850 / special commutation module, IC2 / BM8525 / special frequency conversion processing circuit, FDJ / complex machine. At the same time, refer to Figure 7 As shown, the wire is wound on the winding frame: wire number 1.12, layered and densely wound 800 turns, and the layers are insulated with glass fiber tarpaulin. Referring to the overall structural relationship in Figure 1, follow the steps below to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com