High performance self-adaption gradient water absorber

An adaptive, water absorber technology, applied in the field of agricultural irrigation, can solve the problems of impurity blockage, slow water entering the system, no water absorber device, etc., and achieve the effect of easy cleaning, small water absorption resistance and high water absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

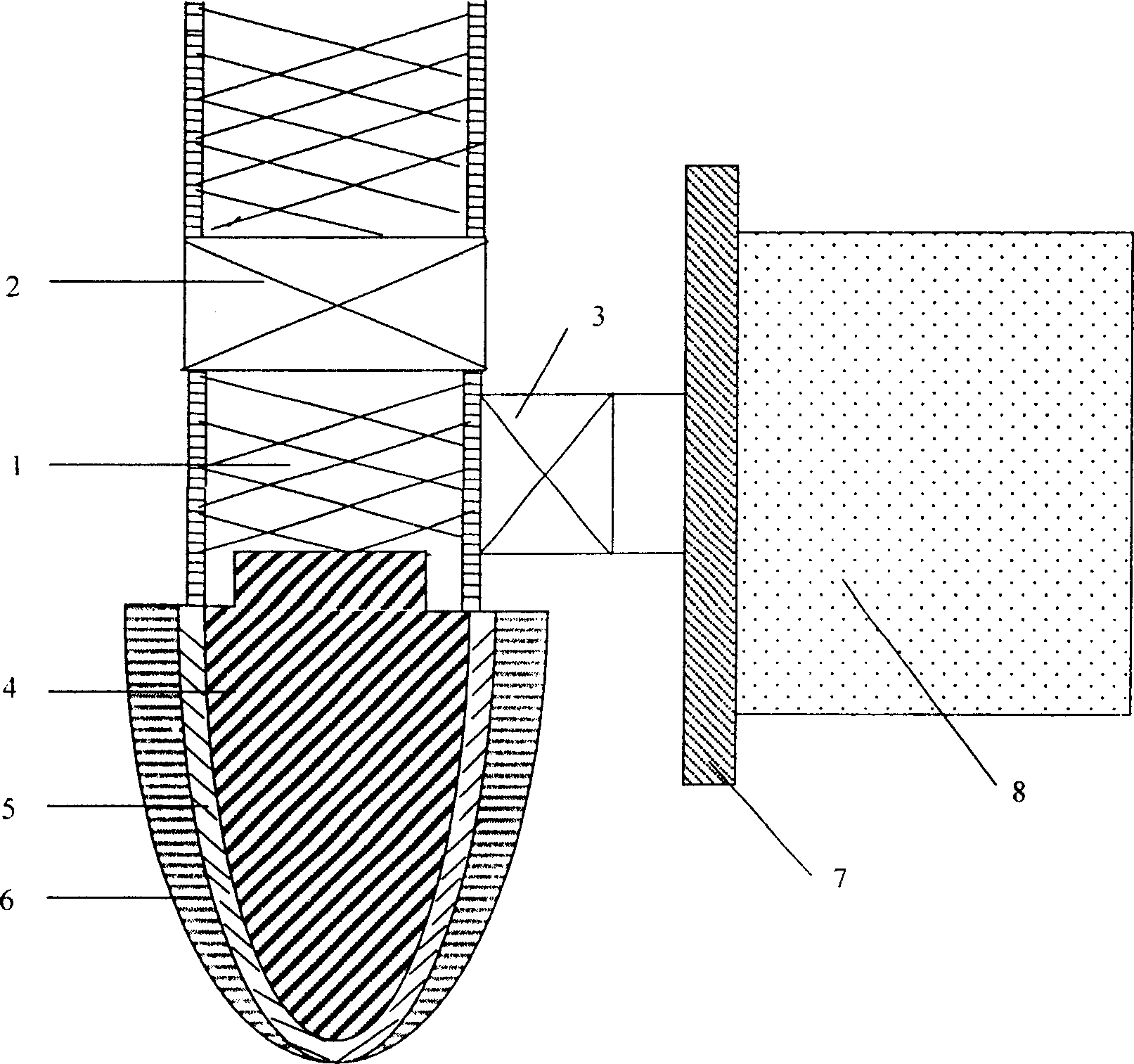

[0008] The high-performance self-adaptive gradient water aspirator of the present invention comprises a capillary hose 1, a capillary hose valve 2 connected to one end of the capillary hose 1, and a gradient water suction head connected to the other end of the capillary hose valve 2, which is arranged at the end and cleaned by Pressure washer with valve 3 connected to capillary hose 1. Wherein, the gradient suction head is composed of a capillary suction pipe 4 , a primary filter 5 wrapped outside the capillary suction 4 , and a water-soluble sealing coating 6 wrapped outside the primary filter 5 . The pressure washer is composed of a base 7 and a high-pressure bag 8 arranged on the base 7 and connected with the cleaning valve 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com