External electrode fluorescent lamp with transmitting film coated internal wall

A technology with external electrodes and fluorescent lamps, which is applied in the field of fluorescent lamps, can solve problems such as low driving voltage, high luminous brightness, and unstable working status, and achieve the effects of enhanced electron emission capability, large discharge current, and guaranteed stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

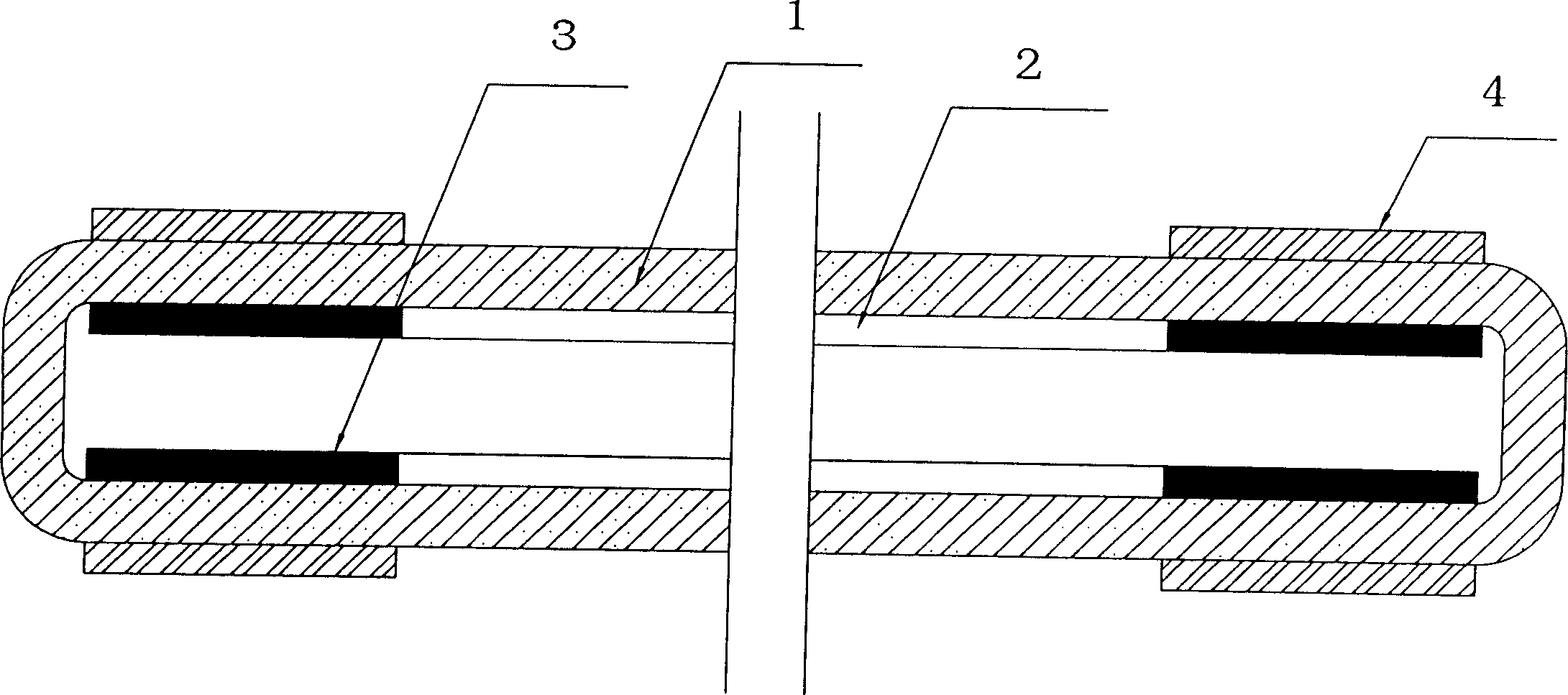

[0008] Control attached picture , its structure is coated with fluorescent powder 2 on the surface of the middle section of the inner wall of the glass tube 1, coated with metal emission film 3 on the two ends of the inner wall of the glass tube 1, and external electrodes 4 are arranged on the two ends of the surface of the glass tube 1.

[0009] The manufacturing method of the external electrode fluorescent lamp with the inner wall coated with the emission film, the process steps are divided into one, cutting the glass tube into the corresponding size, and cleaning; Emitting film; 3. Remove the metal emitting film at both ends of the sealing part by chemical etching; 4. Apply fluorescent powder, bake off the adhesive in the powder, and wipe off the remaining powder on the sealing part; 5. One end of the glass tube is sealed; 6. Exhaust, fill inert mixed gas, inject mercury, and seal off from the exhaust system; 7. Secondary seal off; The outer electrode coated with graphite ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com