Valve of underground well for controlling gas

A ground well and air control technology, which is applied in the direction of lifting valve, valve details, valve device, etc., can solve the problems of insufficient lubrication of the pull rod, increased trouble, inconvenient construction, etc., and achieve the effect of reasonable structural design, easy opening, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

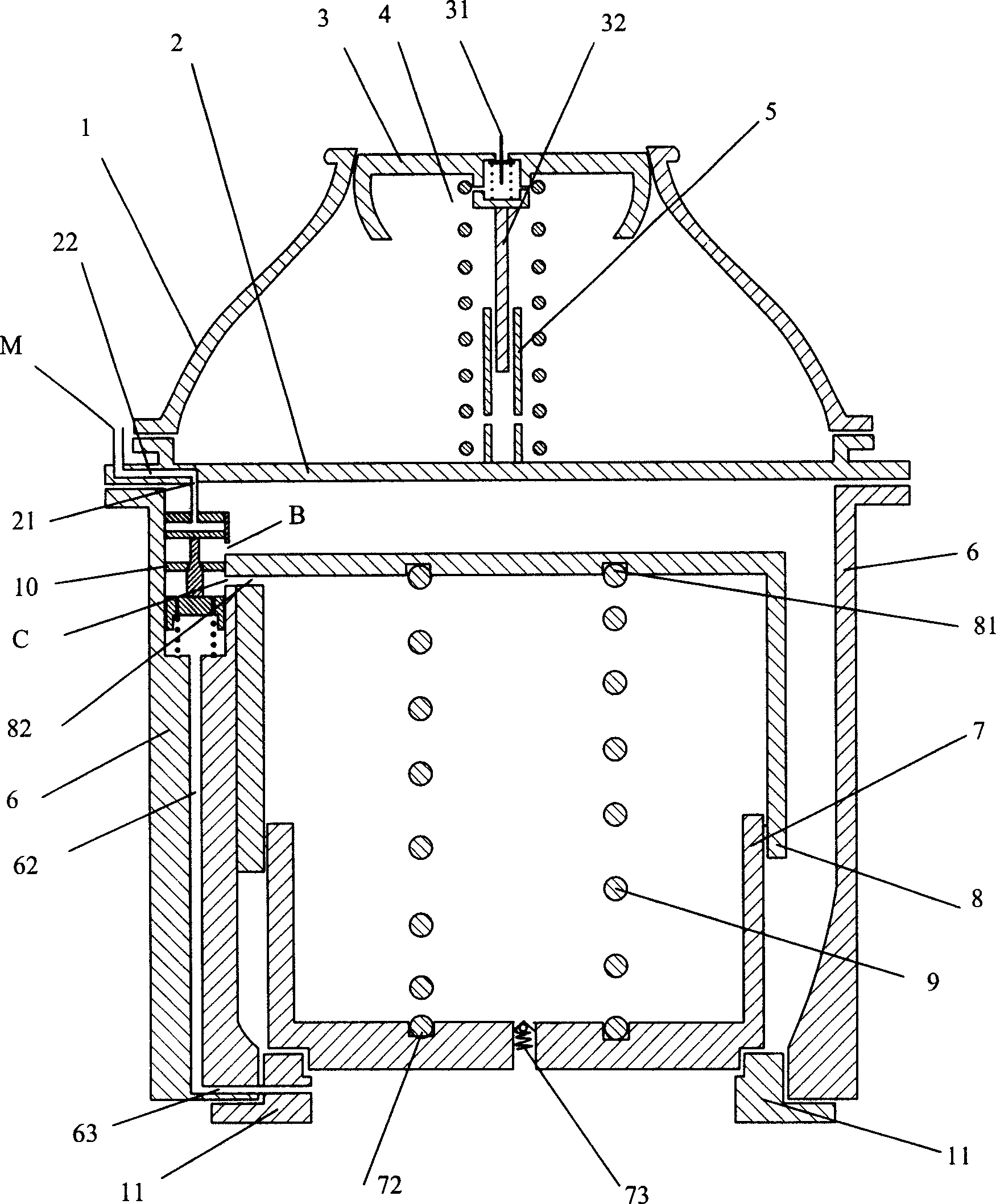

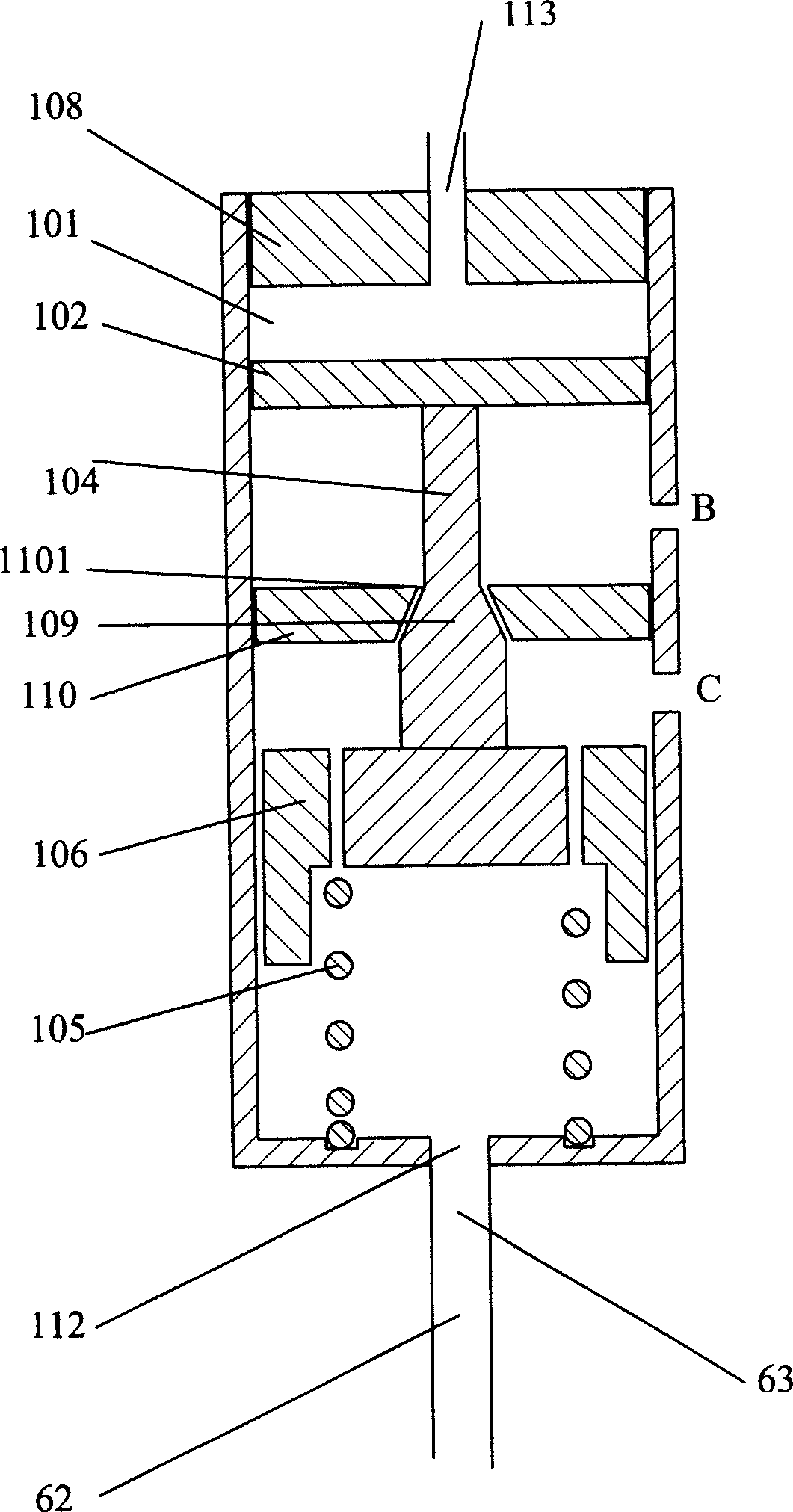

[0031] Such as figure 1 , Shown in 2, the present invention is provided with joint valve, main valve, air control valve and pressure device valve. The joint valve is provided with a joint valve body 1, a joint valve base 2, a guide piston 3, a guide piston spring 4 and a guide piston spring seat 5. The joint valve base 2 is connected, the guide piston 3 is arranged in the joint valve body 1, the piston rod 32 of the guide piston 3 is inserted into the guide piston spring seat 5, and the guide piston spring seat 5 is fixed on the center of the upper surface of the joint valve base 2, and the guide piston The spring 4 is sleeved on the piston rod 32 of the pilot piston 3 and the spring seat 5 of the pilot piston. A pressure device valve 31 is provided on top of the pilot piston 3 .

[0032] The main valve is provided with a main valve body 6, a main piston 7, a main piston sleeve 8, a main piston spring 9 and a main valve seat 11. The top of the main valve body 6 is integrate...

Embodiment 2

[0036] Such as figure 1 , 2, similar to Embodiment 1, the difference is that the main valve body 6 and the joint valve are separated into two independent parts.

Embodiment 3

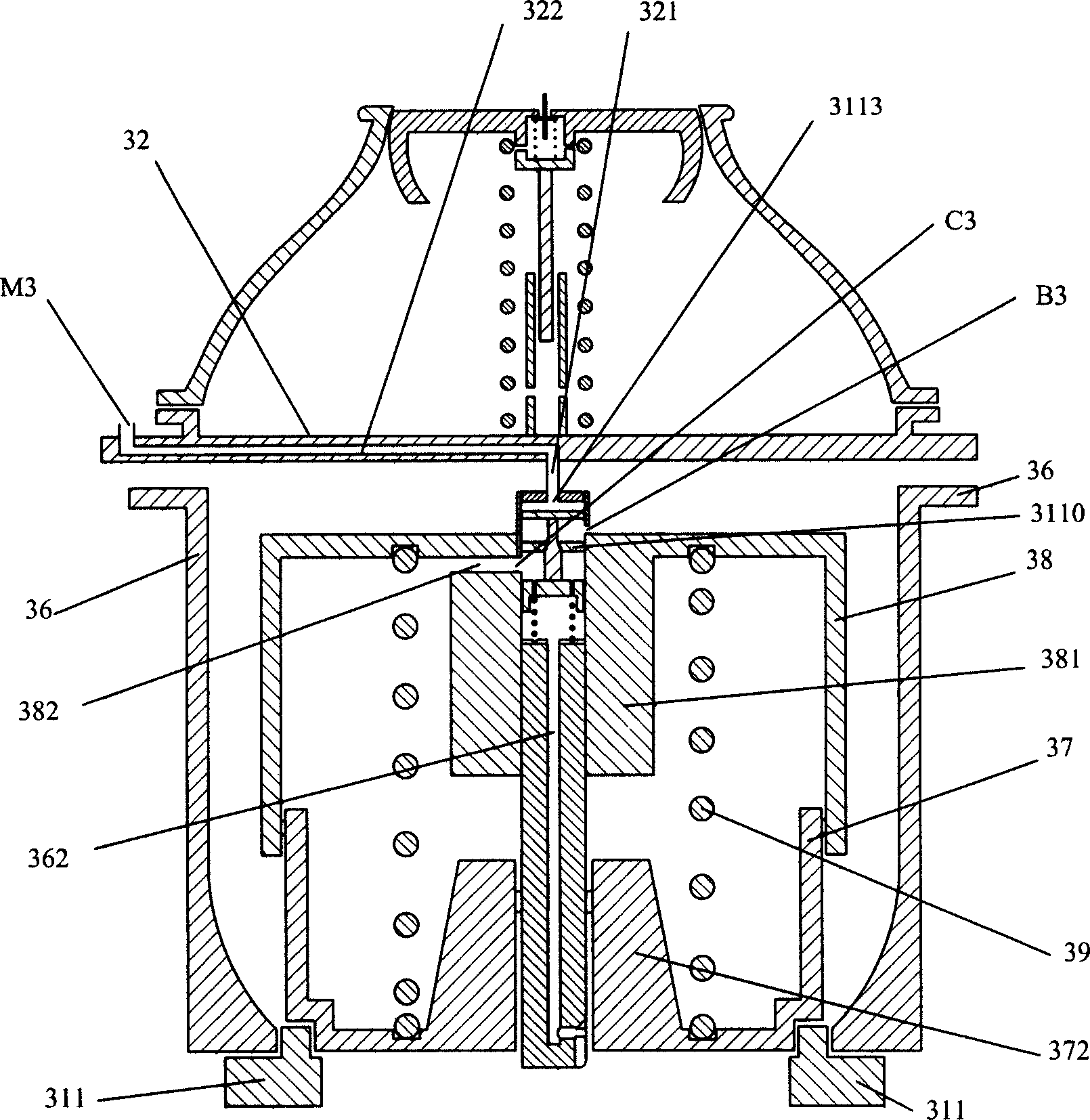

[0038] Such as image 3 As shown, similar to Embodiment 1, the difference is that the air control valve is arranged on the main piston sleeve 38 in the inner cavity of the main valve body 36, and the oil inlet passage through the oil inlet hole at the bottom of the cylinder body of the cylinder is the same as that arranged on the main piston. The channel 362 of the inner cavity of the sleeve 38 is connected, and the channel 362 of the inner cavity of the main piston sleeve 38 is communicated with the oil pipeline connected to the bottom of the main valve seat 311 below the main piston 37 and the main valve body 36, and the oil hole 382 of the main piston sleeve 38 It is located below the top of the main piston sleeve 38 . The oil hole B3 set on the cylinder wall between the piston and the cylinder inner wall baffle communicates with the inner cavity of the main valve body 36, and the oil hole C3 set on the cylinder wall below the cylinder inner baffle 3110 communicates with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com