Device for determining the rotational speed of a rotating machine part using redundant sensors and evaluation circuits

A technology of rotating machines and sensors, applied in the field of measurement, can solve the problems of losing reliability of results, achieve high availability and improve reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

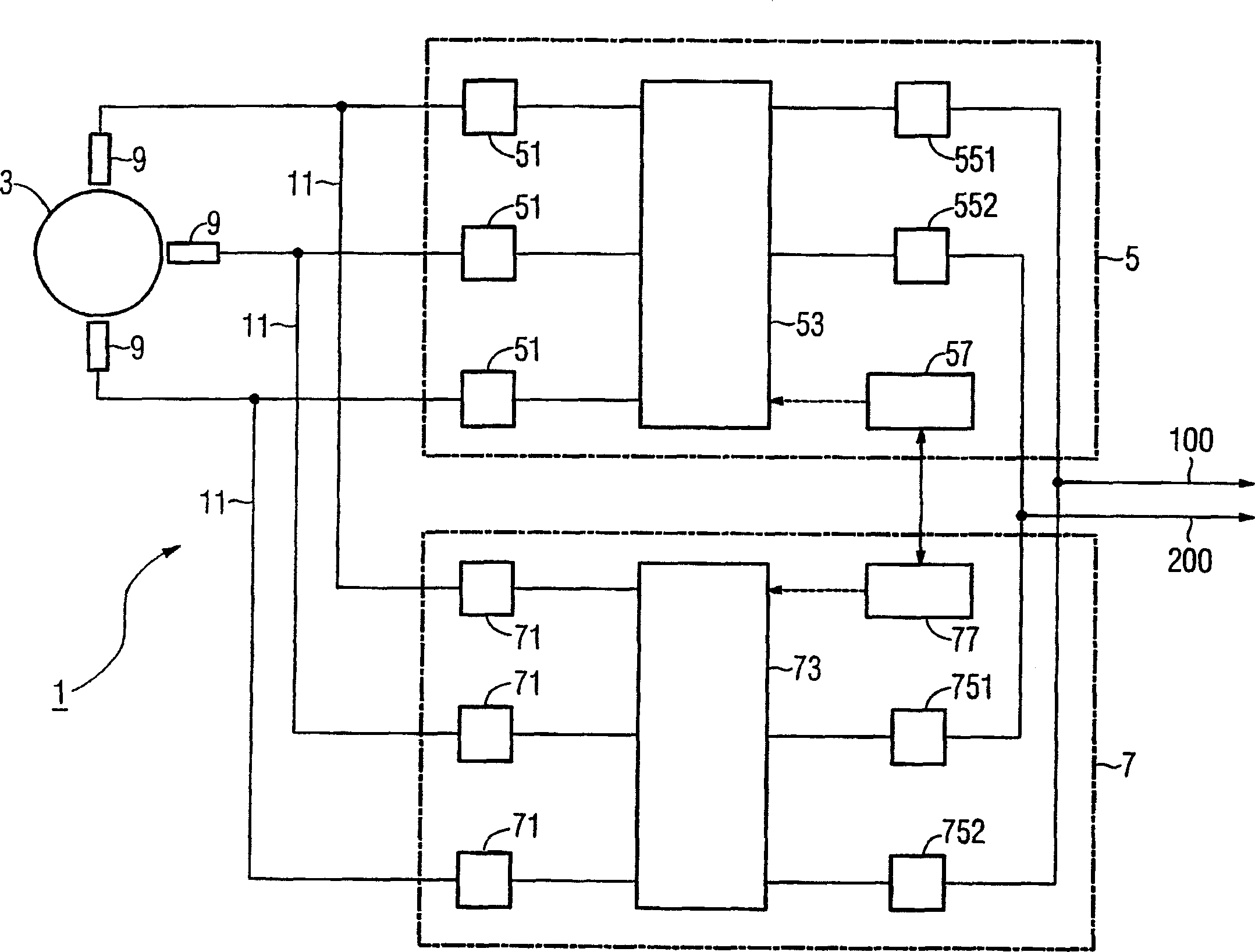

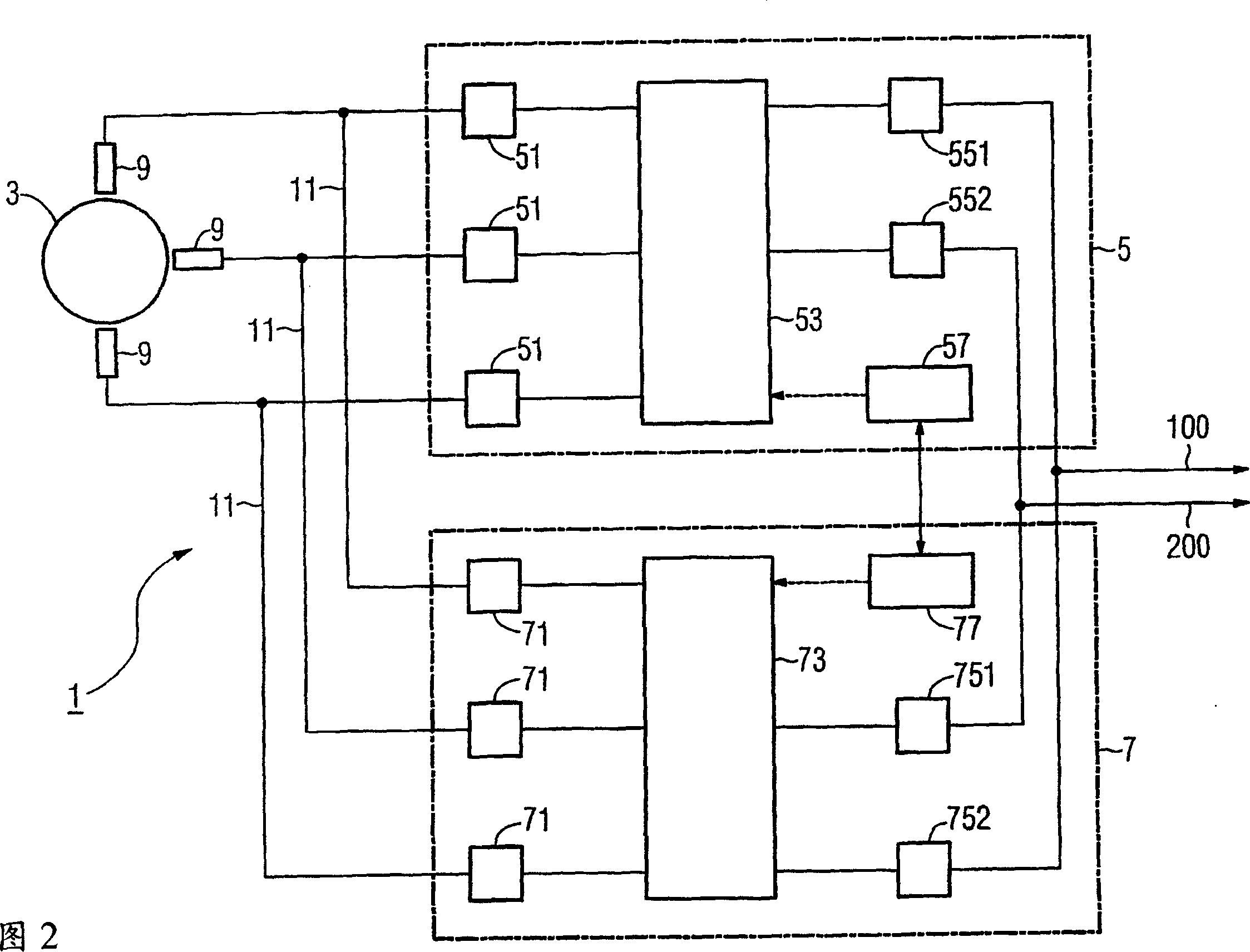

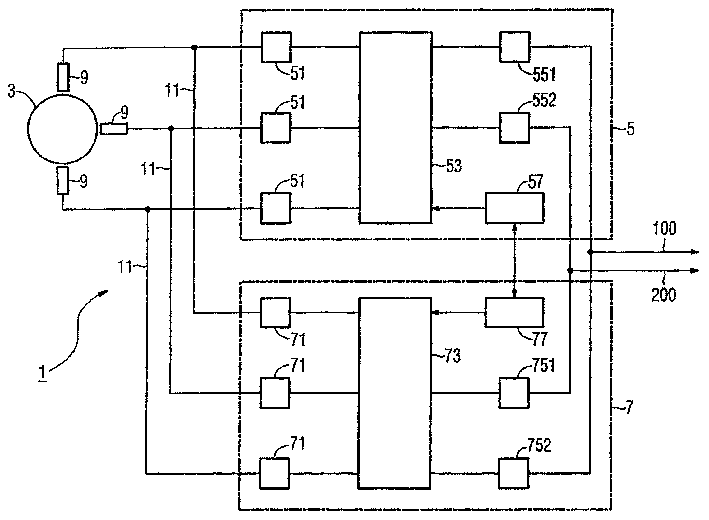

[0086] exist figure 1 A device 1 according to the invention for monitoring the number of revolutions of a rotating machine component 3 , in particular a turbine wheel, is shown in .

[0087] In order to detect the rotational speed signal of the rotating machine part 3 , three rotational speed sensors 9 are arranged on the wheel rim of the rotating machine part 3 , which sensors are arranged for example on the wheel rim and detect rotational marks or gear teeth during operation.

[0088] The output signal 11 of the rotational speed sensor 9 is connected in parallel with the signal input terminals 51 of the first component 5 and the second component 7, wherein the output signal 11 of one rotational speed sensor 9 is connected to the corresponding signal input terminals 51, 51, 71. The signal inputs 51 , 71 of the two components 5 , 7 are each connected to a computing unit 53 , 73 of the respective component 5 , 7 .

[0089] The speed of rotation of the rotary machine part 3 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com