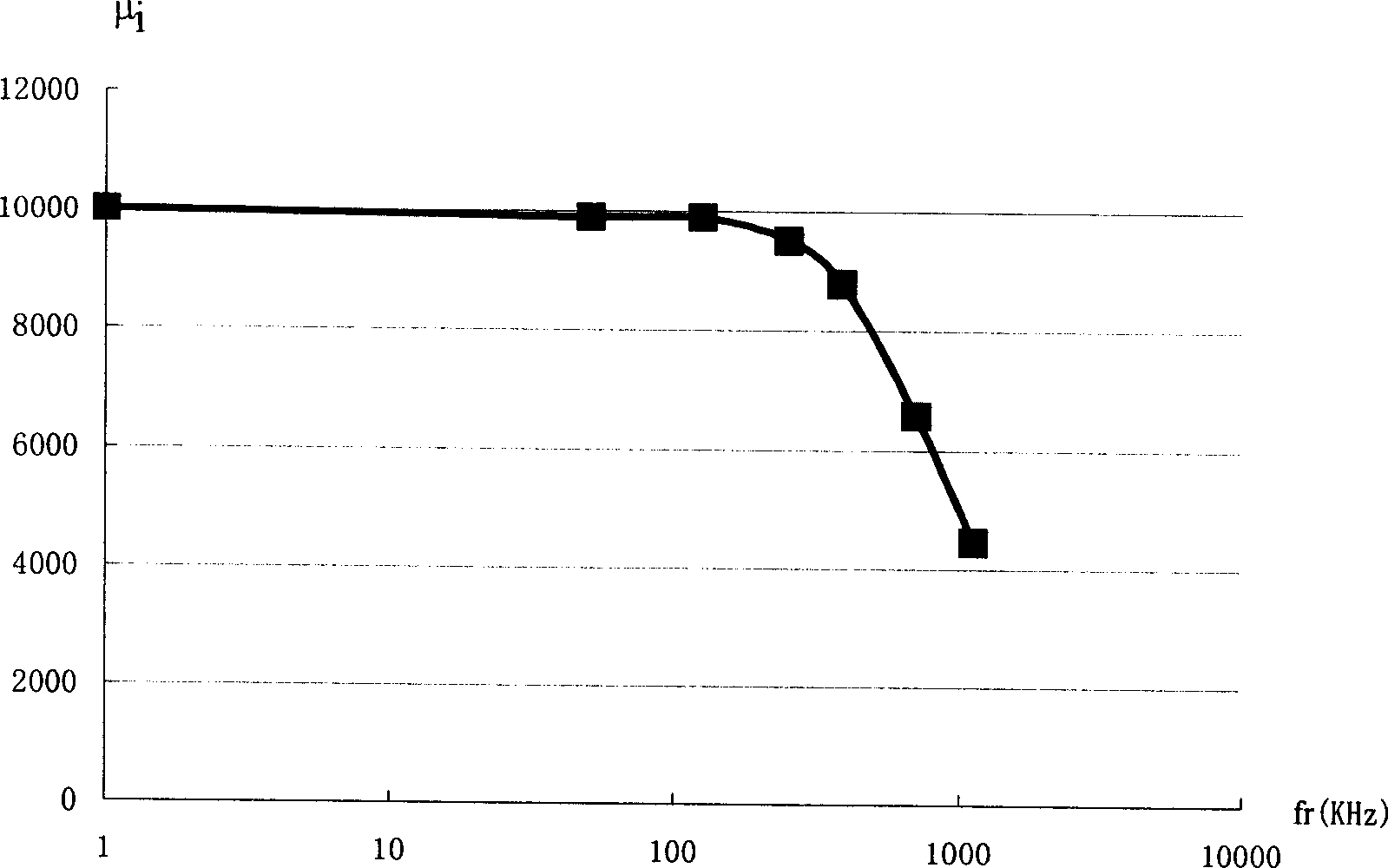

Wide-band manganese-zinc series high-magnetic-conductivity soft magnet oxysome material

A technology of soft magnetic ferrite and high magnetic permeability, applied in the direction of magnetic properties of inorganic materials, can solve problems that have not been solved, and achieve the effect of high cut-off frequency, high initial magnetic permeability, and easy mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Formula: Weight Ratio Molar Ratio

[0022] Fe 2 o 3 : 69.85% 53mol%

[0023] mn 3 o 4 : 15.39% 24mol% (calculated by moles of MnO)

[0024] ZnO: 14.76% 23mol%

[0025] TiO 2 : 0.015% (primary additive)

[0026] SnO 2 : 0.015% (primary additive)

[0027] Li 2 CO 3 : 0.025%

[0028] CoO: 0.05%

[0029] Process steps: first add the additive TiO 2 , SnO 2 with the main component Fe 2 o 3, Mn 3 o 4 Mix with ZnO in a wet method, conduct the first ball milling, the time is about 3 hours, and pre-fire at 880°C±10°C; then add the additive Li to the above-mentioned pre-fired material 2 CO 3 And CoO, the second ball milling time is about 6 hours; after spray granulation, press the ring of T25×15×7.5, sinter at a temperature of 1300 ℃, and keep it for 5 hours.

Embodiment 2

[0031] Formula: Weight Ratio Molar Ratio

[0032] Fe 2 o 3 : 67.7% 51mol%

[0033] mn 3 o 4 : 17.43% 27mol% (calculated by moles of MnO)

[0034] ZnO: 14.87% 22mol%

[0035] CaCO 3 : 0.03% (primary additive)

[0036] MgO: 0.015% (primary additive)

[0037] Bi 2 o 3 : 0.02%

[0038] CoO: 0.05%

[0039] Process steps: first add the additive CaCO 3 , MgO and the main component Fe 2 o 3 , Mn 3 o 4 Wet mixed with ZnO, ball milled for the first time for about 3 hours, and pre-fired at 920°C±10°C; then added the additive Bi to the above-mentioned pre-fired material 2 o 3 And CoO, the second ball milling time is about 5.5 hours; after spray granulation, press the ring of T25×15×7.5, sinter at a temperature of 1320 ° C, and keep it for 5 hours.

Embodiment 3

[0041] Formula: Weight Ratio Molar Ratio

[0042] Fe 2 o 3 : 70.24% 54mol%

[0043] mn 3 o 4 : 15.19% 24mol% (calculated by moles of MnO)

[0044] ZnO: 14.57% 22mol%

[0045] CaCO 3 : 0.03% (primary additive)

[0046] CuO: 0.02% (primary additive)

[0047] Nb 2 o 5 : 0.02%

[0048] CoO: 0.01%

[0049] Mo 2 o 3 : 0.04%

[0050] V 2 o 5 : 0.015%

[0051] Process steps: first add the additive CaCO 3 , CuO and the main component Fe 2 o 3 , Mn 3 o 4 Wet mixed with ZnO, ball milled for the first time for about 5 hours, and pre-fired at 890°C±10°C; then add additive Nb to the above-mentioned pre-fired material 2 o 5 Bi 2 o 3 , CoO, Mo 2 o 3 and V 2 o 5 , the second ball milling time is about 6 hours; after spray granulation, press the ring of T25×15×7.5, sinter at a temperature of 1320° C., and keep it warm for 5 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com