Pressure limiting valve with direct hydraulic damper

A pressure-limiting valve and hydraulic technology, applied in the direction of safety valves, balance valves, valve devices, etc., can solve problems such as inability to guarantee filling and damage, and achieve the effect of smooth guidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

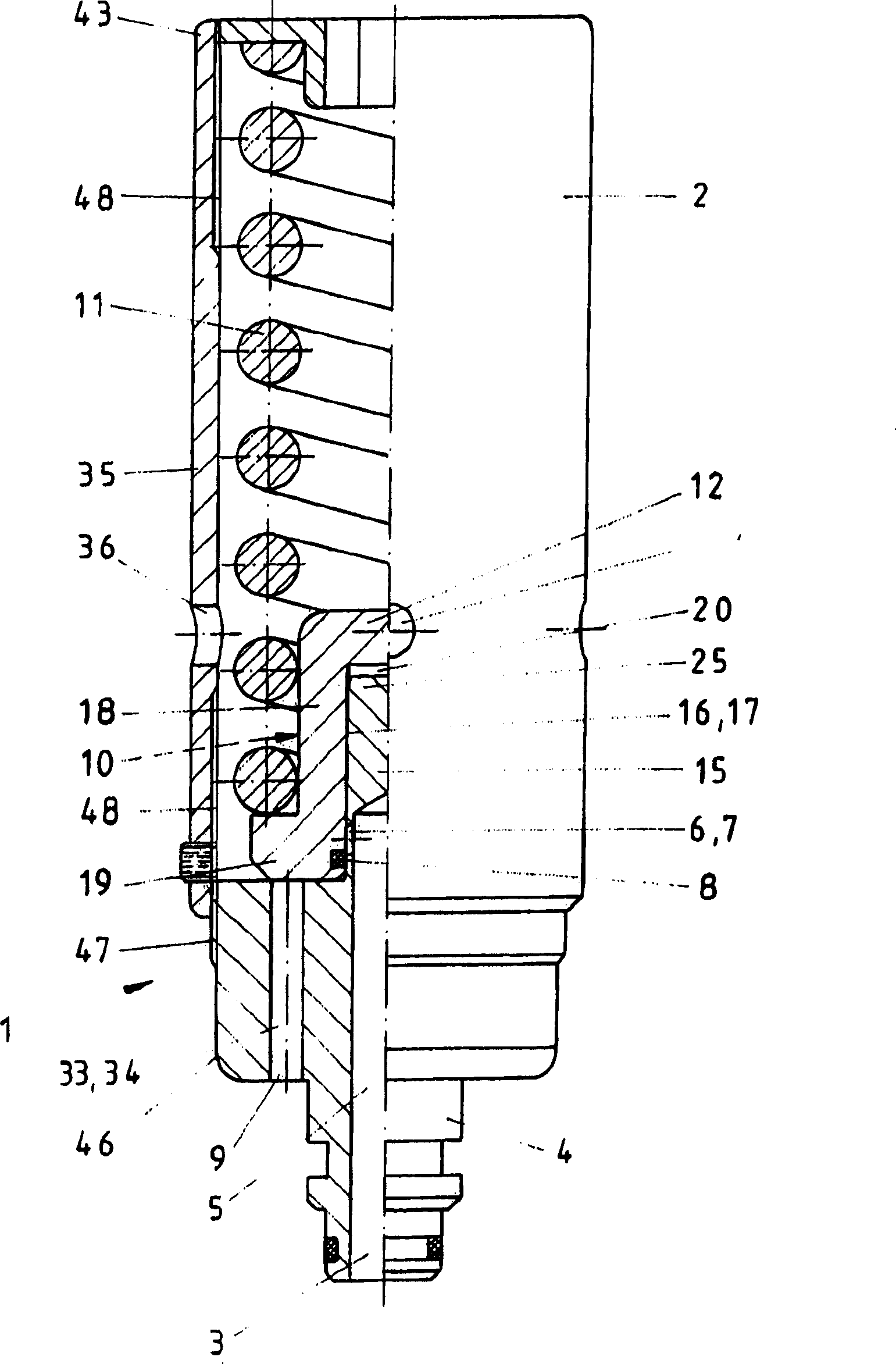

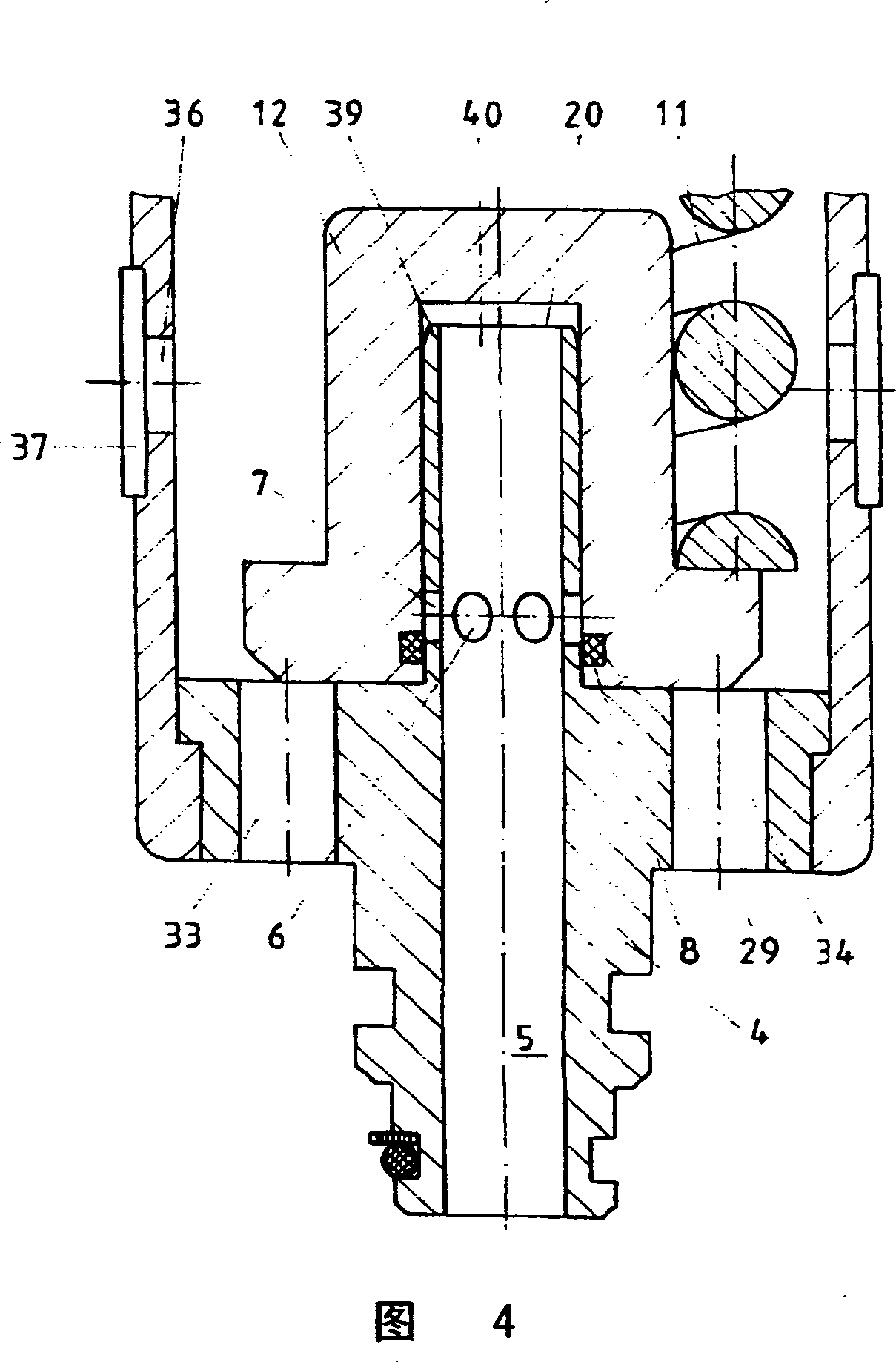

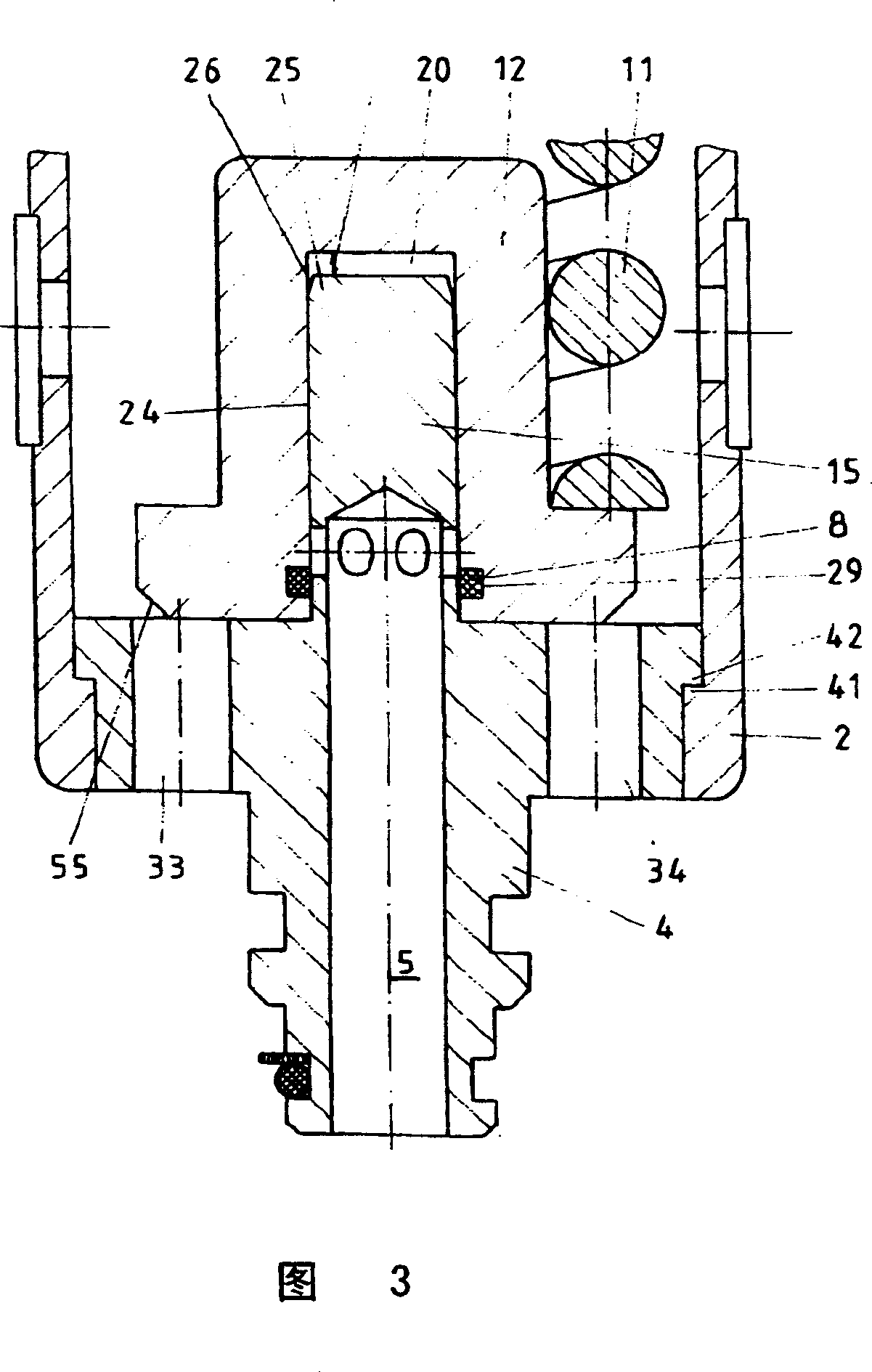

[0032] figure 1 A pressure limiting valve 1 is shown in section, the valve body 2 having the shape of a sleeve. A valve spring 11 is accommodated in this valve body 2 by a spring tray 12 , wherein a specially shaped spring tray 12 , which will be described in more detail below, stands on the connection 4 and guides the spring tray in a sliding manner on the connection. To this end, the connection 4 has a piston 15 and a sealing point between the stationary piston 15 and the movable spring tray 12 , which forms the so-called closing part 10 . The inlet port 3 of the valve body 2 is normally closed relative to the outlet port 9 by means of this closing element 10 . Only when a correspondingly high pressure occurs at the blind bore 5 of the joint 4, for example due to a rock impact, is this pressure liquid passed through the radial bores 6, 7 and the contact surfaces 16, 17 and the orifice 52 shown here and the damping chamber 20 are pressed into the valve spring tray 12, there...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com