Valve rod mechanism for superhigh temperature high pressure valve

A high-pressure valve, ultra-high temperature technology, used in valve heating/cooling devices, lift valves, valve details, etc., can solve the problems of low valve stem strength, large temperature difference between inside and outside, easy to break, etc., to achieve compact structure and improve strength. , the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

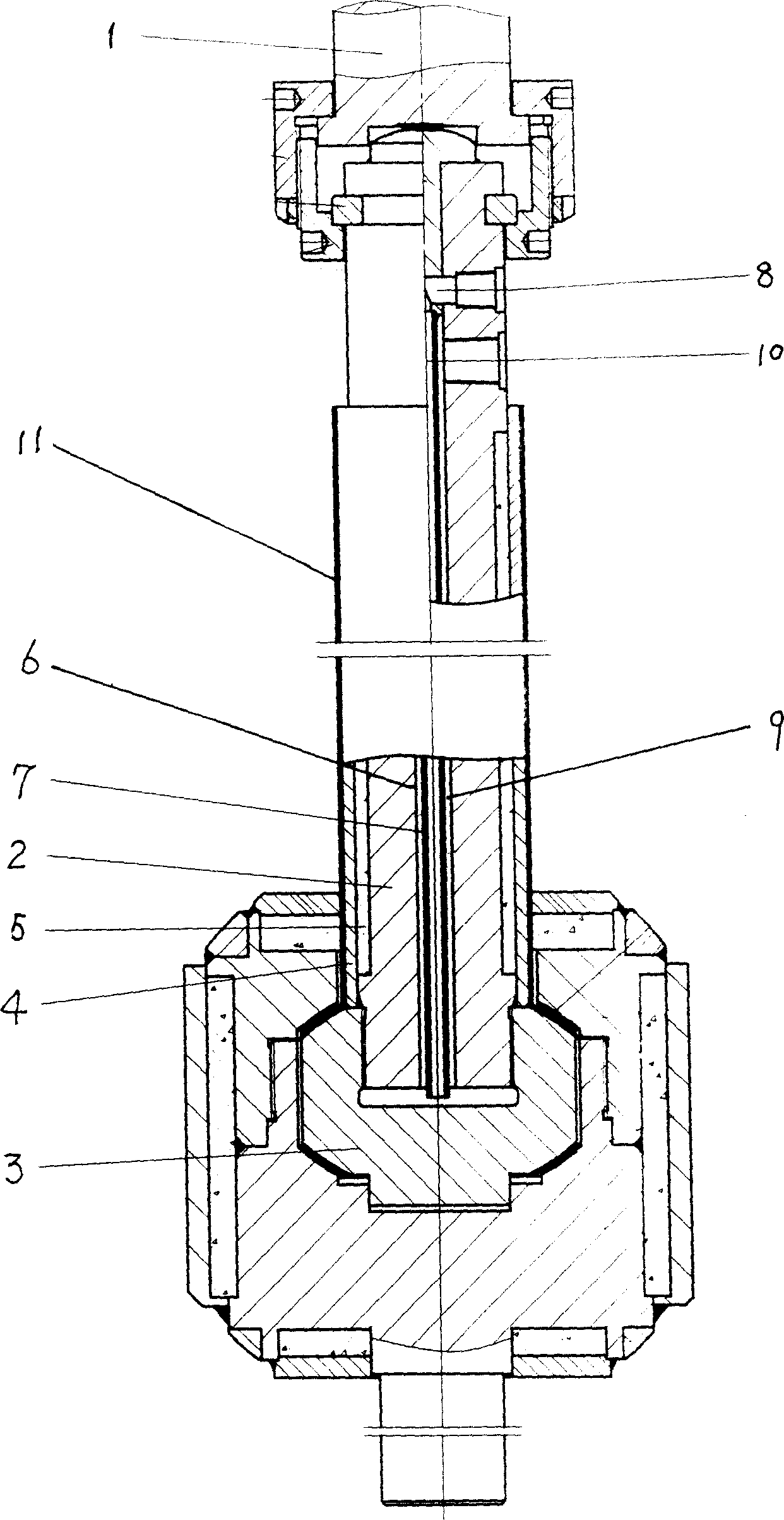

[0009] As shown in the figure, the present invention includes upper and lower valve stems 1 and 2 which are movably connected and a valve stem head 3 fixedly connected to the end of the lower valve stem 2. The round surface is provided with a protective layer 11, and a heat insulating layer 5 is provided between the protective sleeve 4 and the lower valve stem 2. Cooperate, the cooling air pipe 7 is installed in the inner hole 6 of the lower valve stem 2, the cooling air pipe 7 communicates with the air inlet 8, and the gap 9 between the cooling air pipe 7 and the inner hole 6 communicates with the air outlet 10.

[0010] The key of the present invention is that the lower valve stem 2 adopts a four-layer structure, and the outside is called a protective cover 4, which is made of high temperature resistant material GH3128. The lower end of the protective cover 4 and the lower valve stem 2 are welded together with the valve stem 3, and the upper end of the protective cover 4 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com