Organic electroluminescent display and packaging method thereof

A packaging method and luminescence technology, which is applied in the direction of electroluminescence light source, electric light source, light source, etc., can solve the problems of weakened glass strength, poor adhesion between metal back cover and glass substrate, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

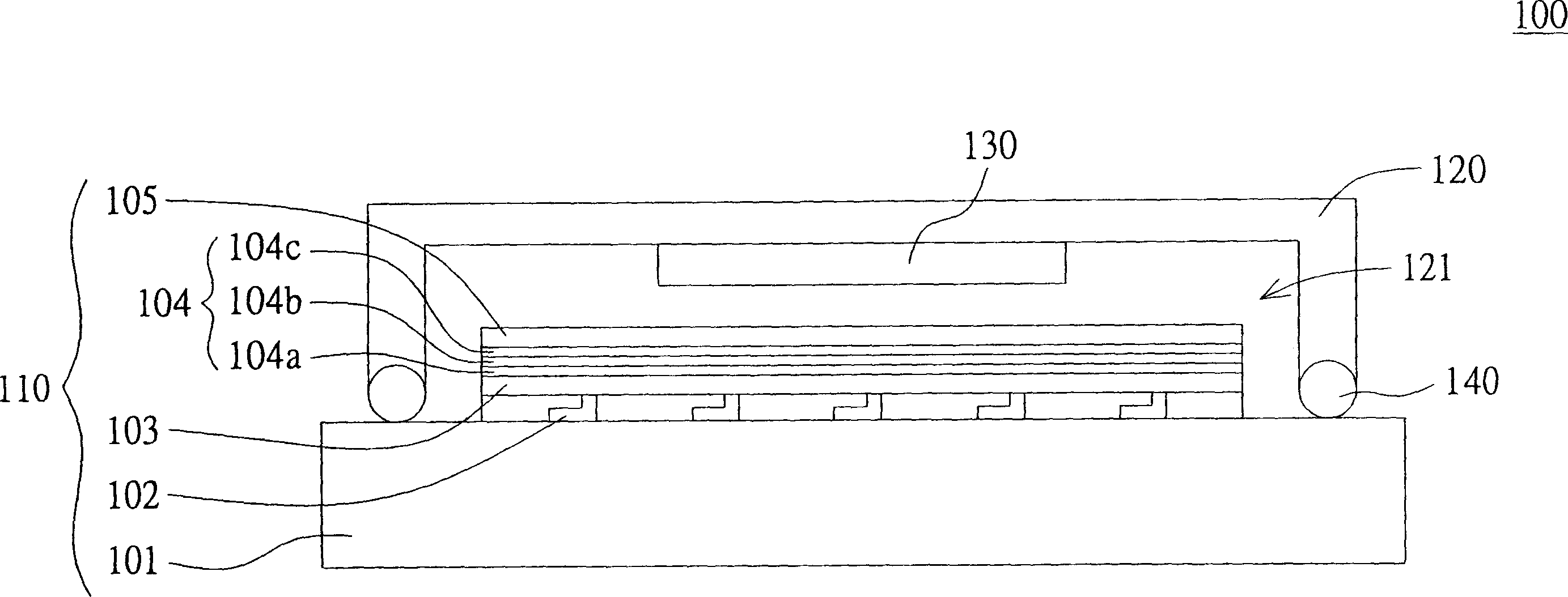

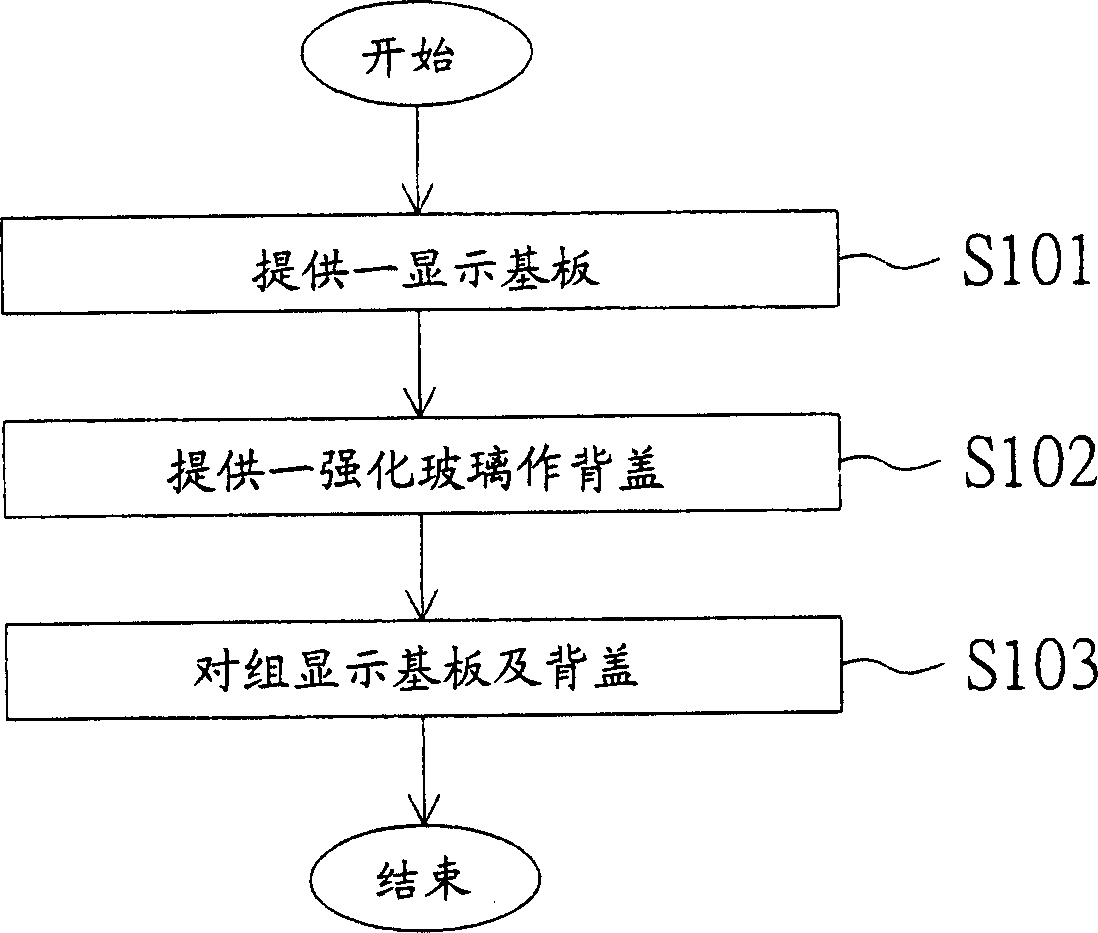

[0033] The present invention proposes an organic electro-luminescent display (Organic Electro-Luminescent Display, OELD), which includes a display substrate and a back cover, and the back cover is assembled on the display substrate. The back cover is made of tempered glass, which can greatly increase the strength of the back cover and effectively prevent the fragments from falling. Hereinafter, an organic electroluminescent display and its packaging method are taken as an example to describe in detail. However, this embodiment is only an implementation mode under the inventive spirit of the present invention, and does not limit the protection scope of the present invention.

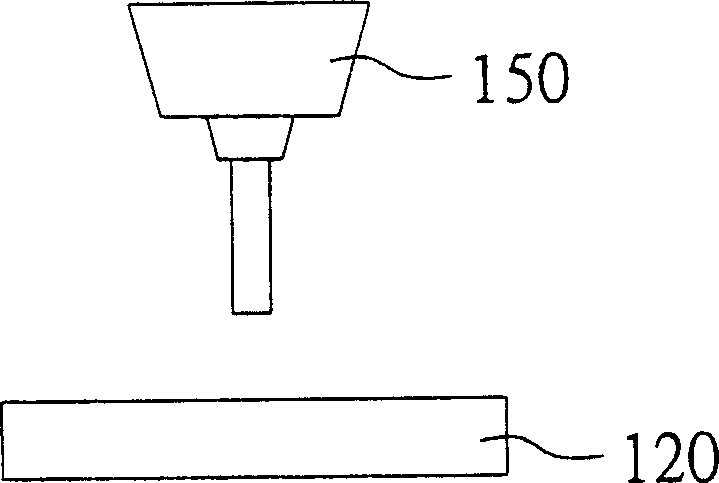

[0034] Please refer to figure 1 , which shows a graph according to a preferred embodiment of the present invention. The Organic Electro-Luminescent Display (OELD) 100 of this embodiment includes a display substrate 110 , a back cover 120 , a desiccant 130 and an adhesive.

[0035] The display substrate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com