Chemical oil-refining method for preparing low carbon olefin and arene

A technology for low-carbon olefins and aromatics, applied in the field of catalytic conversion, which can solve problems such as low propylene yield, movement of reforming catalysts, complicated regeneration process, and inability to produce low-carbon olefins and aromatics at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

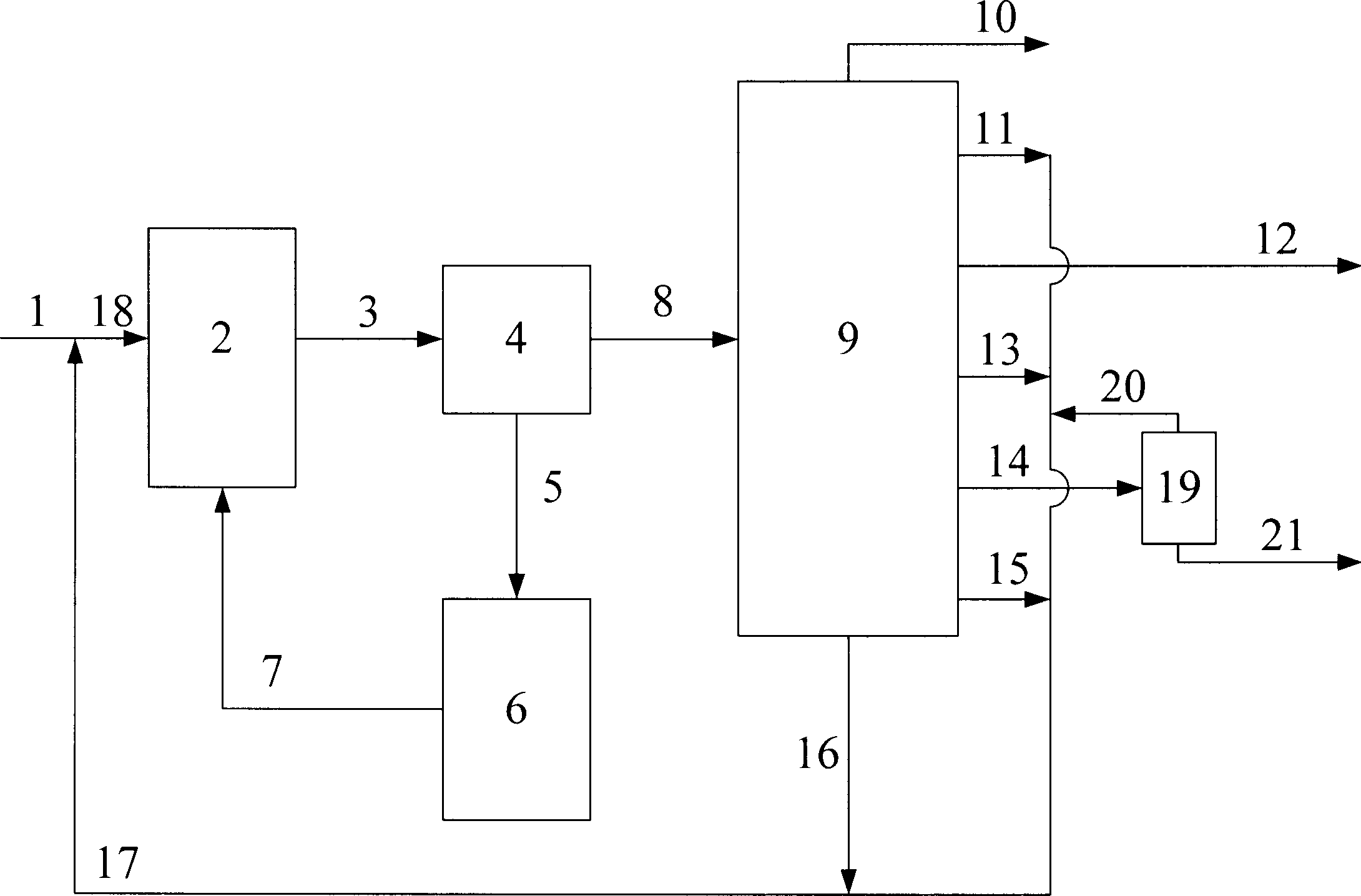

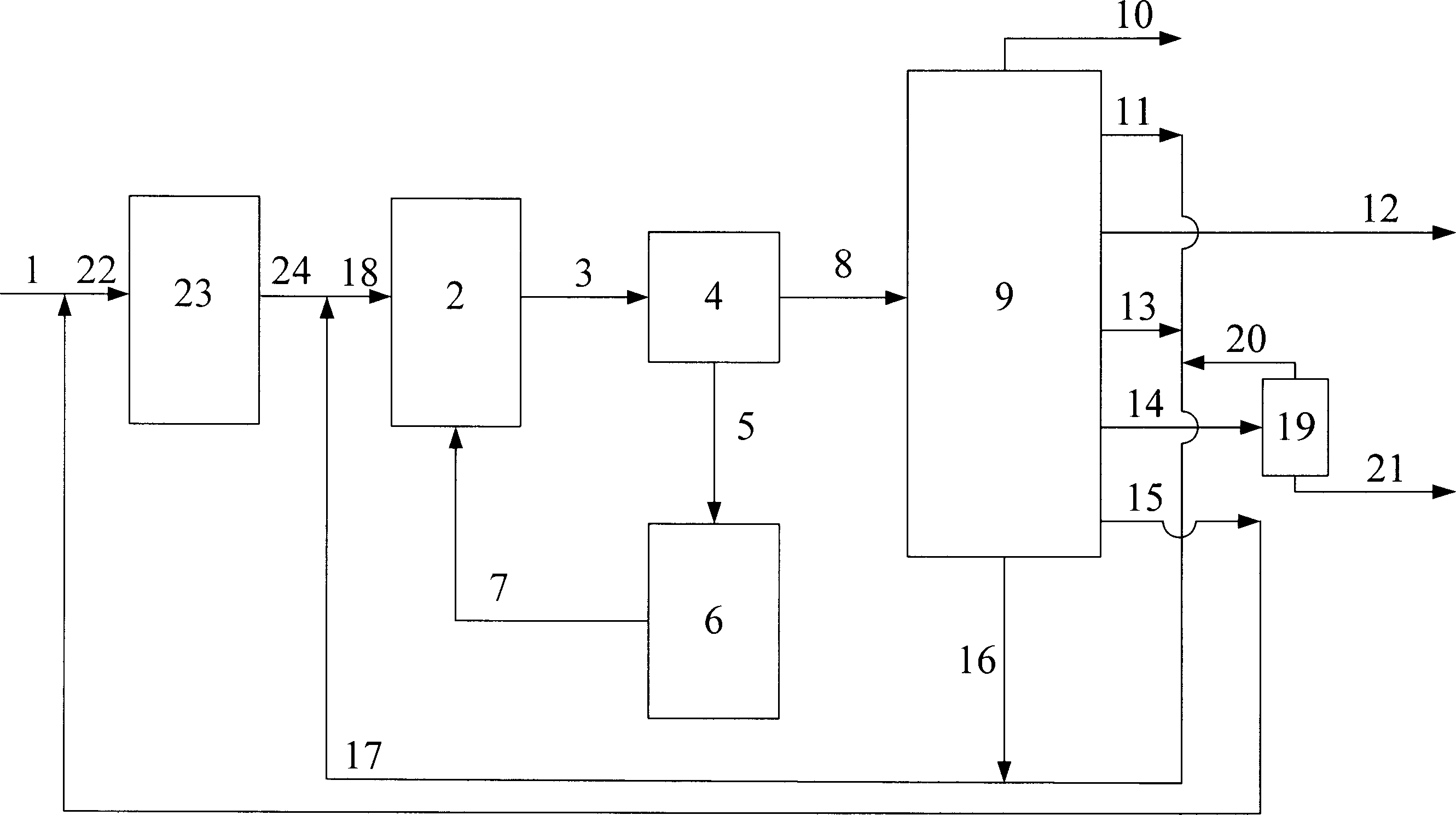

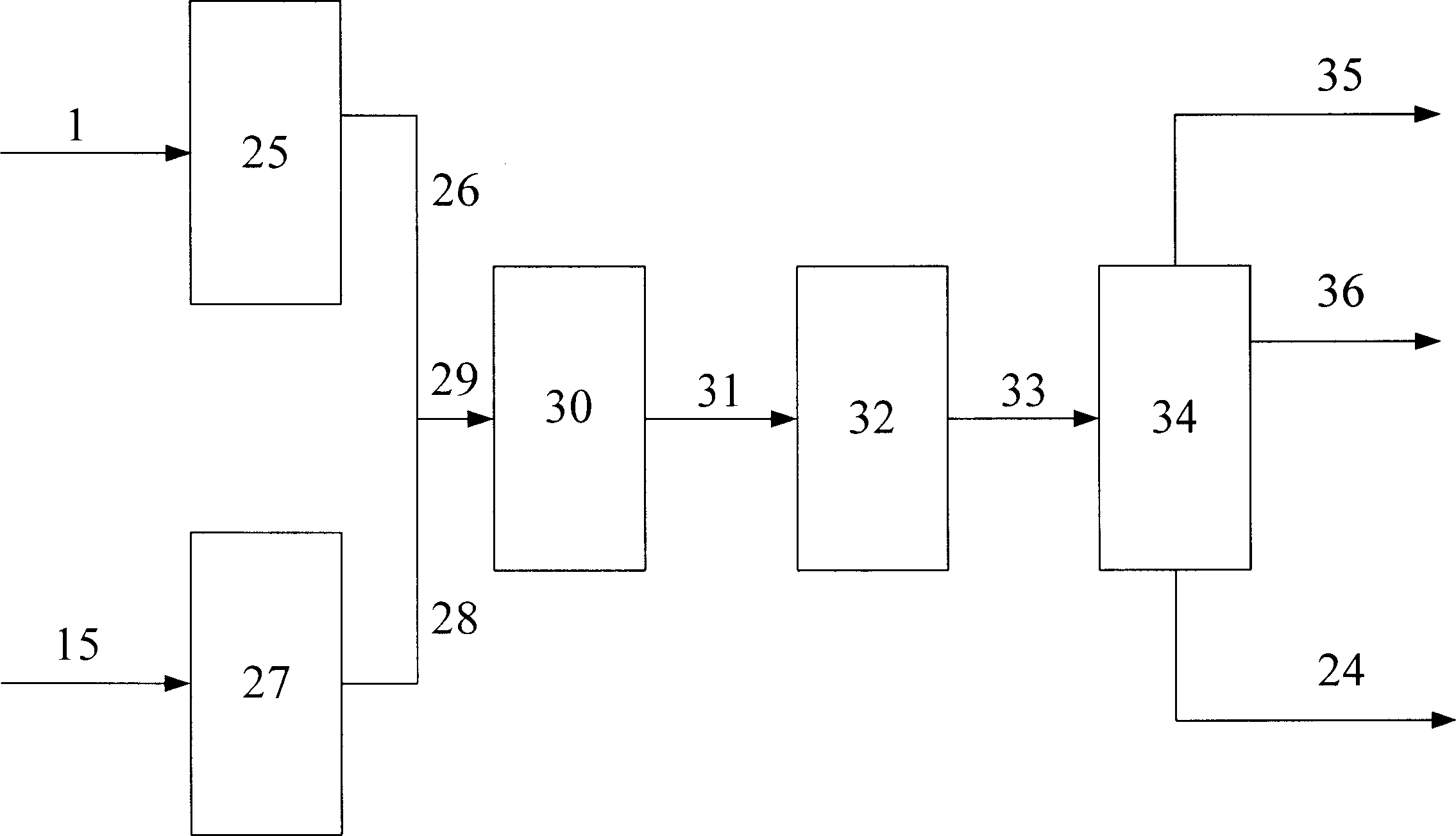

Method used

Image

Examples

Embodiment 1

[0073] After the raw material oil A is hydrotreated first, the resulting hydrogenated oil (the hydrogen content increases from 12.40% by weight to 13.54% by weight, and the content of aromatics decreases from 44.1% by weight to 20.0% by weight) is used as the raw material for catalytic cracking, and is used as the raw material for catalytic cracking in the medium-sized riser +The test is carried out in a fluidized bed reactor, and finally the product is separated, in which only the oil slurry is circulated to the riser, and other circulating materials are not circulated. The operating conditions and product distribution of hydrotreating and catalytic cracking are shown in Table 2.

[0074] It can be seen from Table 2 that the yields of propylene and ethylene are as high as 32.97% by weight and 12.63% by weight respectively, and the yields of toluene and xylene are 1.93% by weight and 4.05% by weight respectively.

Embodiment 2

[0076] Raw oil B is directly used as raw material for catalytic cracking, and is tested in a medium-sized riser + fluidized bed reactor, and finally the product is separated, and only the oil slurry is circulated to the riser, C 4 -C 6 Circulation to the fluidized bed, other circulating materials are not circulated. The operating conditions and product distribution of catalytic cracking are shown in Table 2.

[0077] It can be seen from Table 2 that the yields of propylene and ethylene are as high as 30.46% by weight and 18.31% by weight respectively, and the yields of toluene and xylene are 2.45% by weight and 7.38% by weight respectively.

Embodiment 3

[0079] After the raw material oil C is hydrotreated first, the resulting hydrogenated oil is used as the raw material for catalytic cracking. The test is carried out in a medium-sized riser + fluidized bed reactor, and finally the product is separated, and all the circulating materials are recycled. Among them, ethane and Propane, C 4 -C 6 1. Pyrolysis gasoline raffinate oil is circulated to the fluidized bed, oil slurry is circulated to the riser, and the circulating oil is returned to the hydrotreating reactor. The operating conditions and product distribution of hydrotreating and catalytic cracking are shown in Table 2.

[0080] It can be seen from Table 2 that the yields of propylene and ethylene are as high as 36.86% by weight and 12.89% by weight respectively, and the yields of toluene and xylene are 3.89% by weight and 10.56% by weight respectively.

[0081] Example 1

[0082] Example 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com