Cake box base tray, its producing method and device

A cake box and tray technology, which is applied in transportation and packaging, packaging of vulnerable items, and food packaging, etc., can solve the problems of low production efficiency, rough appearance, and breeding of bacteria, so as to facilitate transportation and portability, reduce manual operations, and guarantee The effect of sanitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

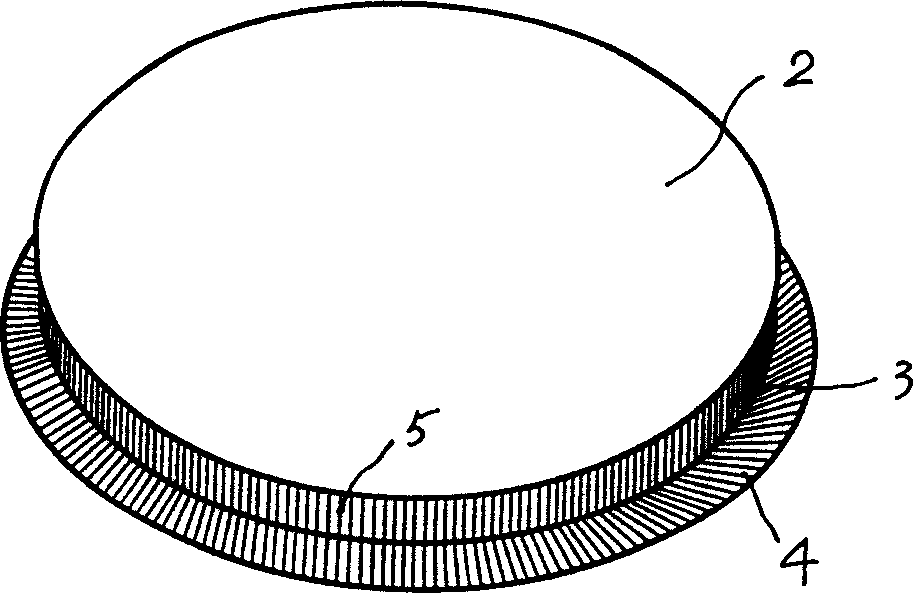

[0021] figure 1 A form of the upper cardboard 1 is shown, with a raised platform 2 in the middle, and creases 5 on the side walls 3 of the platform 2 and the bottom edge 4 of the upper cardboard 1 . The production of the upper cardboard 1 is to stamp the creases 5 on the periphery of the flat cardboard through the indentation die, and punch the raised platform 2 in the concave-convex die, wherein the peripheral part with the creases 5 forms the side wall 3 of the platform and the bottom edge of the upper cardboard 4. The creases 5 are preferably evenly distributed, forming a radial shape with the center of the above cardboard as the axis, so that the side walls 3 and the bottom edge 4 are evenly folded. Before making the cardboard, the paper surface of the flat cardboard can be waterproofed, such as composite plastic film, waterproof coating or polishing.

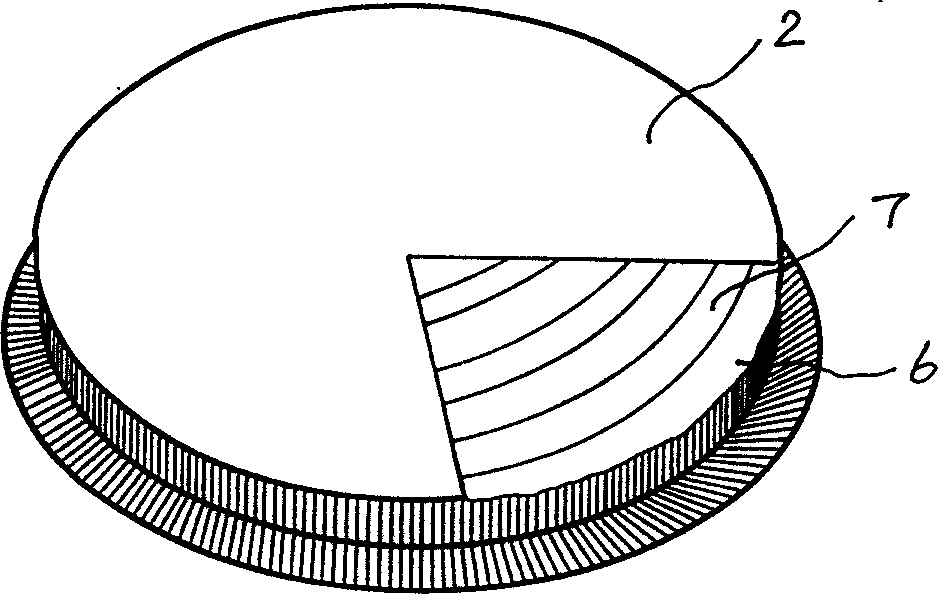

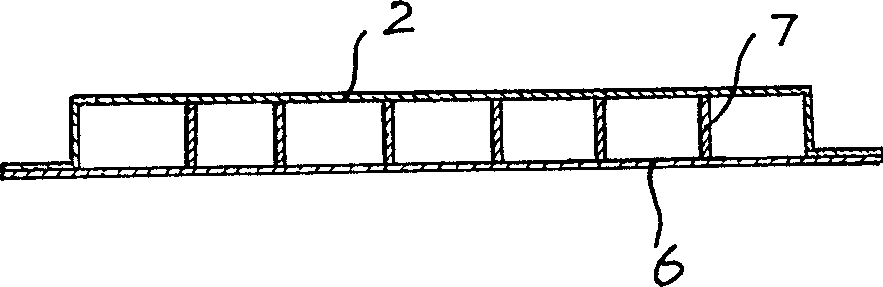

[0022] figure 2 and image 3 The bottom tray of the cake box is shown, including an upper cardboard 1 and a lower ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com