Measuring device for vehicle wheel load

A measuring device and wheel technology, applied in the direction of measuring devices, weighing, special scales, etc., can solve the problem that it can only be installed between two adjacent track splints and hinder the axle, so as to eliminate the phenomenon of overturning and lifting, Removes the effect of internal skew

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

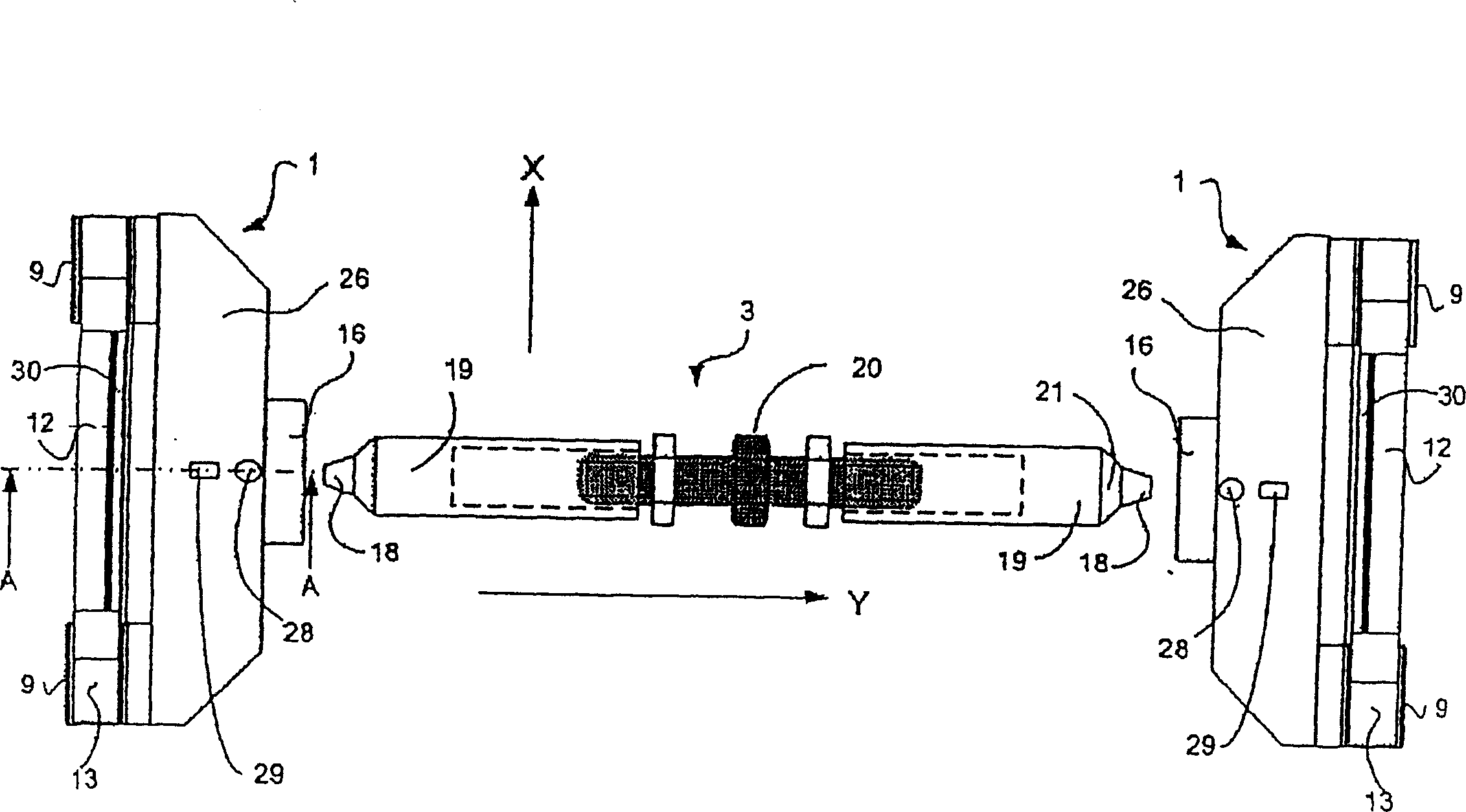

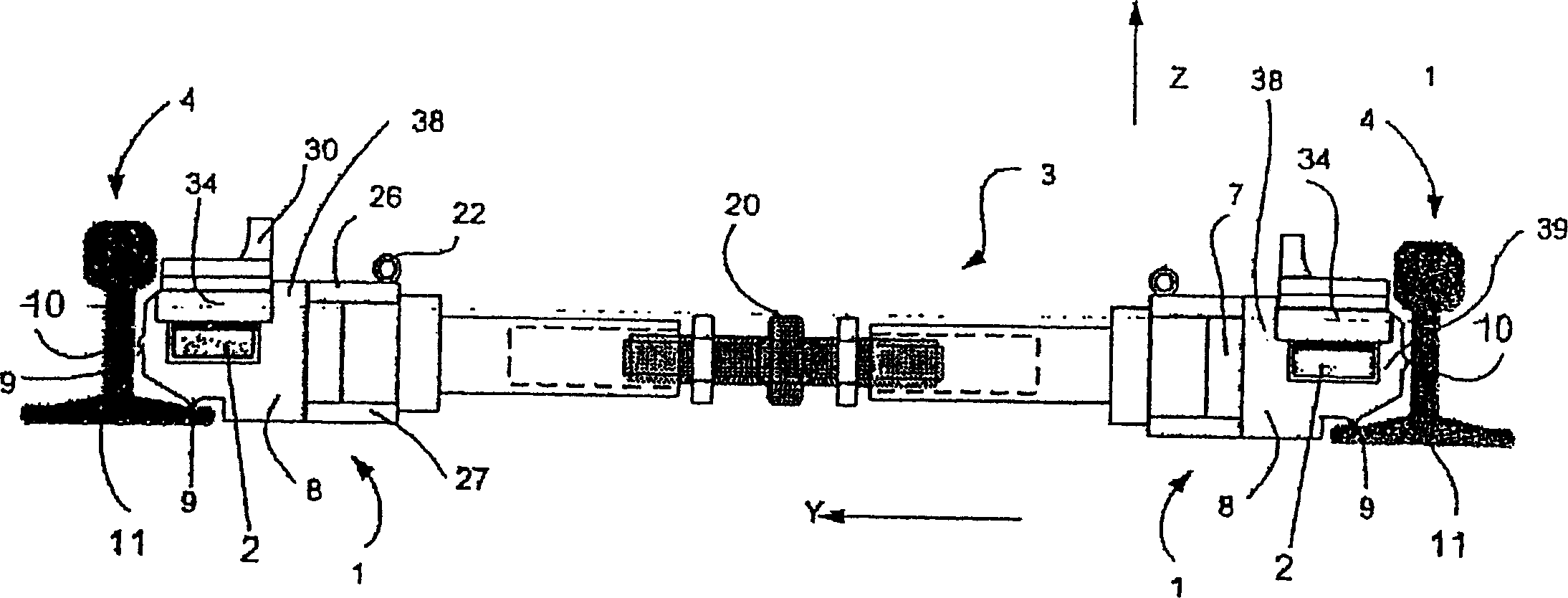

[0044] figure 1 The measuring device is shown in plan view in the installed state. It consists of left and right measuring blocks 1 with built-in weighing bridge 2 ( figure 2 ) and single-arm clamping device 3. In order to prepare for the measurement process, two measuring blocks 1 are pre-installed with a clamping device 3 outside the ballast bed, then installed between the rails 4 and fixedly positioned between the rails 4 by continuing to clamp the clamping device 3 ( figure 2 ).

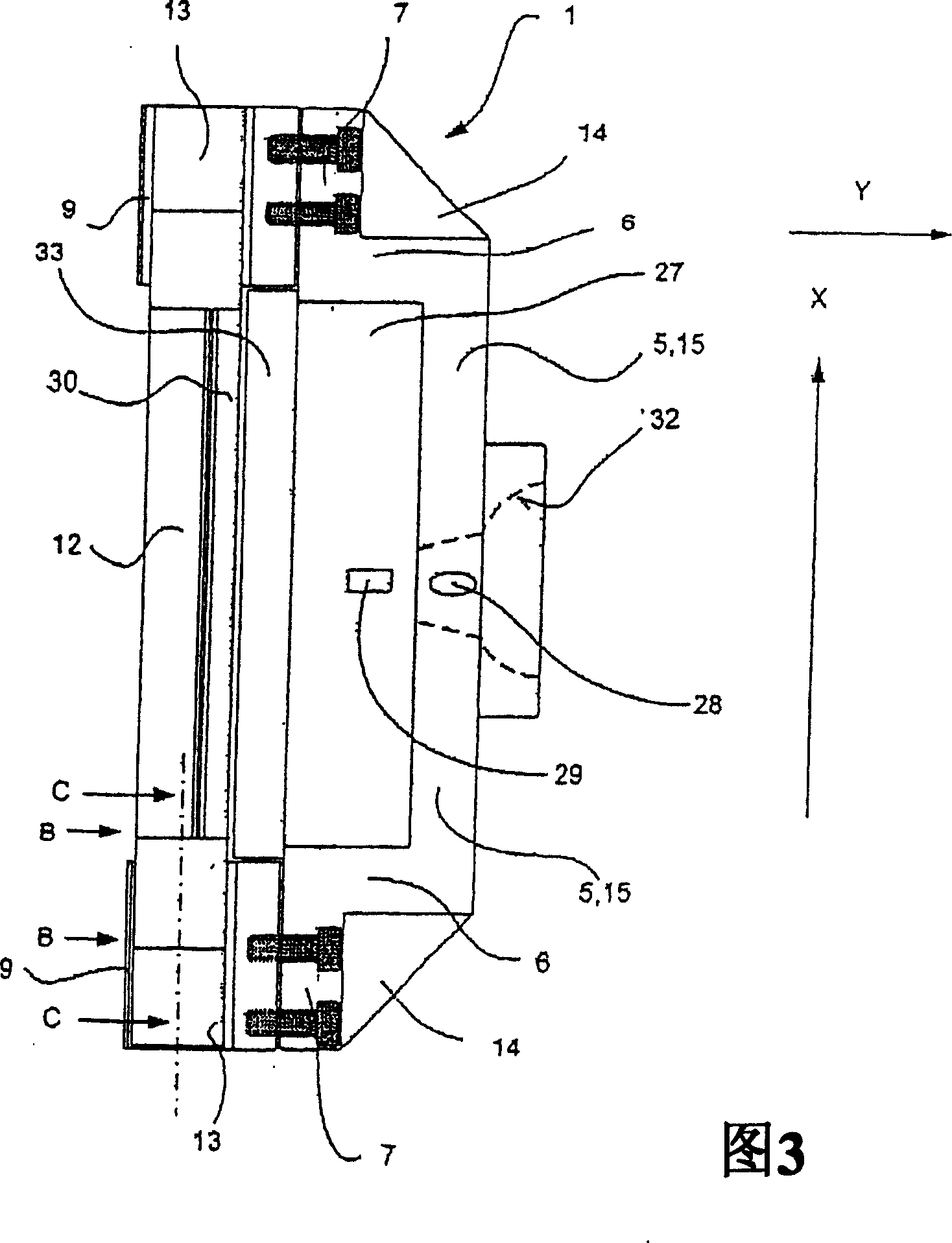

[0045] The measuring block 1 consists of an approximately u-shaped bridge 5 ( FIG. 3 ), which is arranged laterally parallel to the weighing bridge 2 in the x-direction and connects the two support bases 8 of the measuring block 1 . The bridge 5 consists of a strut 15 running parallel to the rails 4, connected at its ends and bent approximately at right angles in the x-direction, each with an outer strut 6, on which is also connected at a roughly right angle a flange 7, which The connection...

Embodiment 2

[0064] The difference from the measuring device described in Example 1 is that this embodiment introduces a measuring device with reinforcement plates 76 that are parallel to one side of the bridge 55 and the second side on the support 66. Be fixedly connected with the third side that has fixed handle 65. With the help of Figure 10-14 Mainly introduce the structural changes of the measuring device in Embodiment 1. Components not mentioned basically correspond to the measuring device of Example 1.

[0065] The measuring device also consists of two load-receiving blocks with built-in measuring sections and components for holding and clamping. The load receiving blocks are constructed as left and right measurement blocks 51 and receive a built-in measurement section each. The measuring block 51 consists of a bridge 55 which is arranged laterally parallel to the weighing bridge 2 in the x-direction and which is connected to the jaw-shaped bearing base 8 of the measuring block ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com