A support mechanism and a work vehicle with the support mechanism

A technology of support mechanism and support end, which is used in vehicle maintenance, lifting vehicle accessories, transportation and packaging, etc., and can solve the problems of complex system and cumbersome operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

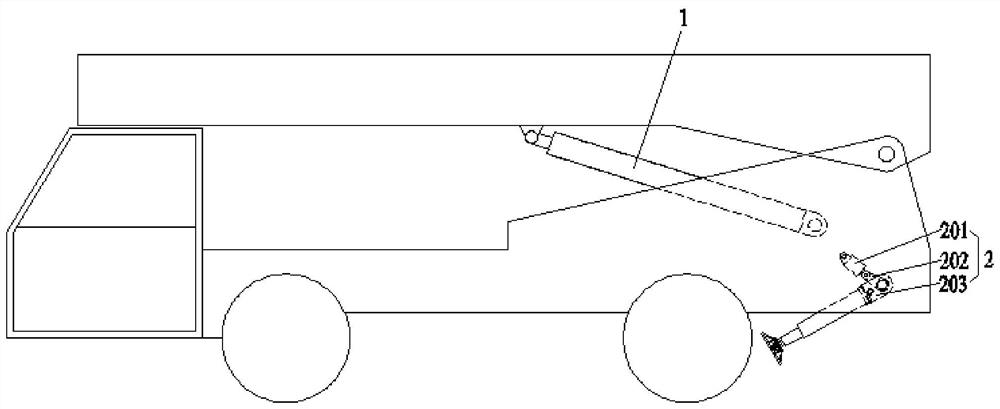

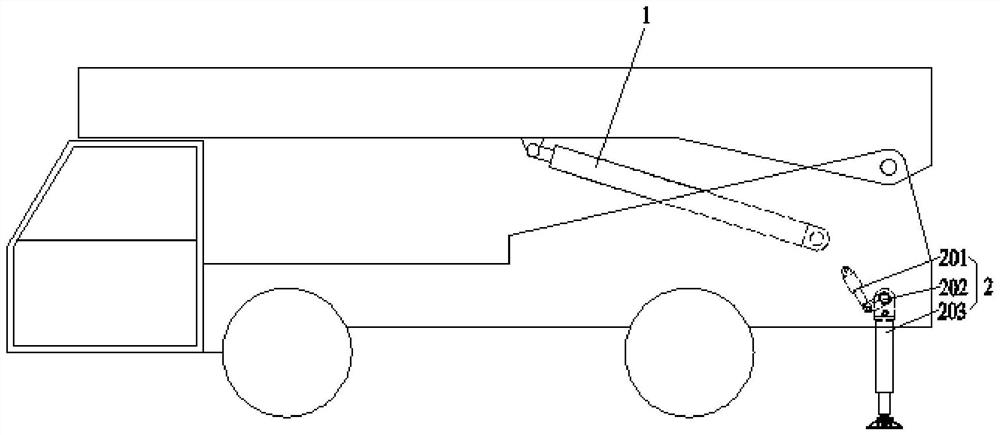

[0052] Such as figure 1 with figure 2 Distance figure 1 Schematic diagram of the initial state structure of the support leg 203 for the existing support mechanism, figure 2 Schematic structural diagram of the state structure for the support leg 203 of the existing support mechanism, from figure 1 with figure 2 This existing support mechanism is seen from two independent systems, one is the body support, and the second is vertical.

[0053] The vehicle body support device 2 is configured to support the vehicle to prevent the vehicle from being tipped, using the leg swing hydraulic cylinder 201 to connect the leg 203, and there is a intermediate link 202 between the two, and the retractable of the hydraulic cylinder 201 through the leg swing. The intermediate link 202 is rotated, and the intermediate link 202 drives the support leg 203 that is fixed to the intermediate link 202 for rotation, and the support leg 203 is rotated to the horizontal surface to support the vehicle support....

Embodiment 2

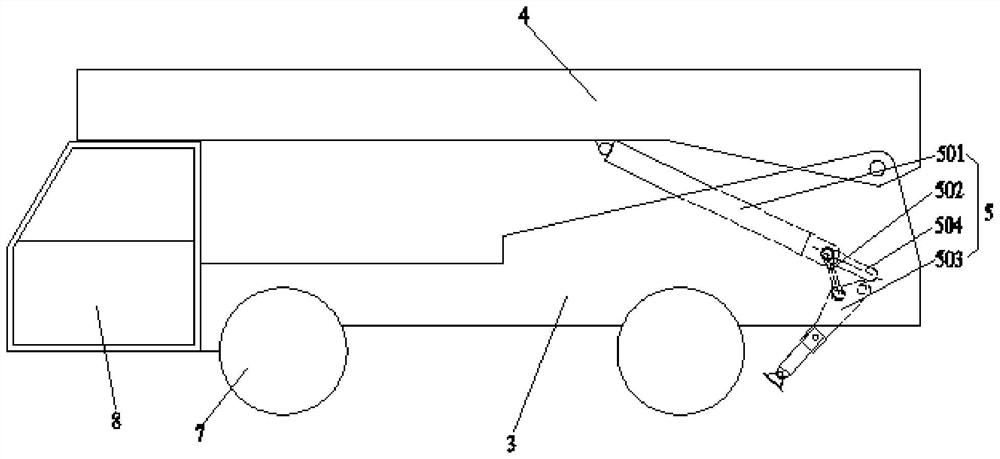

[0081] Such as image 3 with Figure 4 As shown, a working vehicle with a support mechanism is applied to the support mechanism as described in Example 1:

[0082] One end of the vertical drain member 501 is hinged to the upper 4 of the vehicle, and the other end is hinged to one end of the connecting rod 502, and the other end of the connecting rod 502 is connected to the shaft or support end of the leg 503. One end of the leg 503 is hinged to the frame 3 opposite the support end, and the frame 3 is attached to the end of the two at the end of the two;

[0083] The support mechanism further includes a strip bit structure 504 that limits the mild leg of the hinge 505 of the connecting rod 502 to control the hinge 505 to control the support 503 swing angle;

[0084] The hinge point of the vertical drain member 501 and the upper 4 can be disposed in the middle of the upper portion 4, the hinge point of the leg 503 and the frame 3 can be disposed at the tail of the frame 3, the strip l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com