Electromechanical furniture drive mechanism

A transmission device and furniture technology, applied in the direction of electromechanical devices, household appliances, electric components, etc., can solve problems such as change, and achieve the effects of simple manufacturing, solid structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

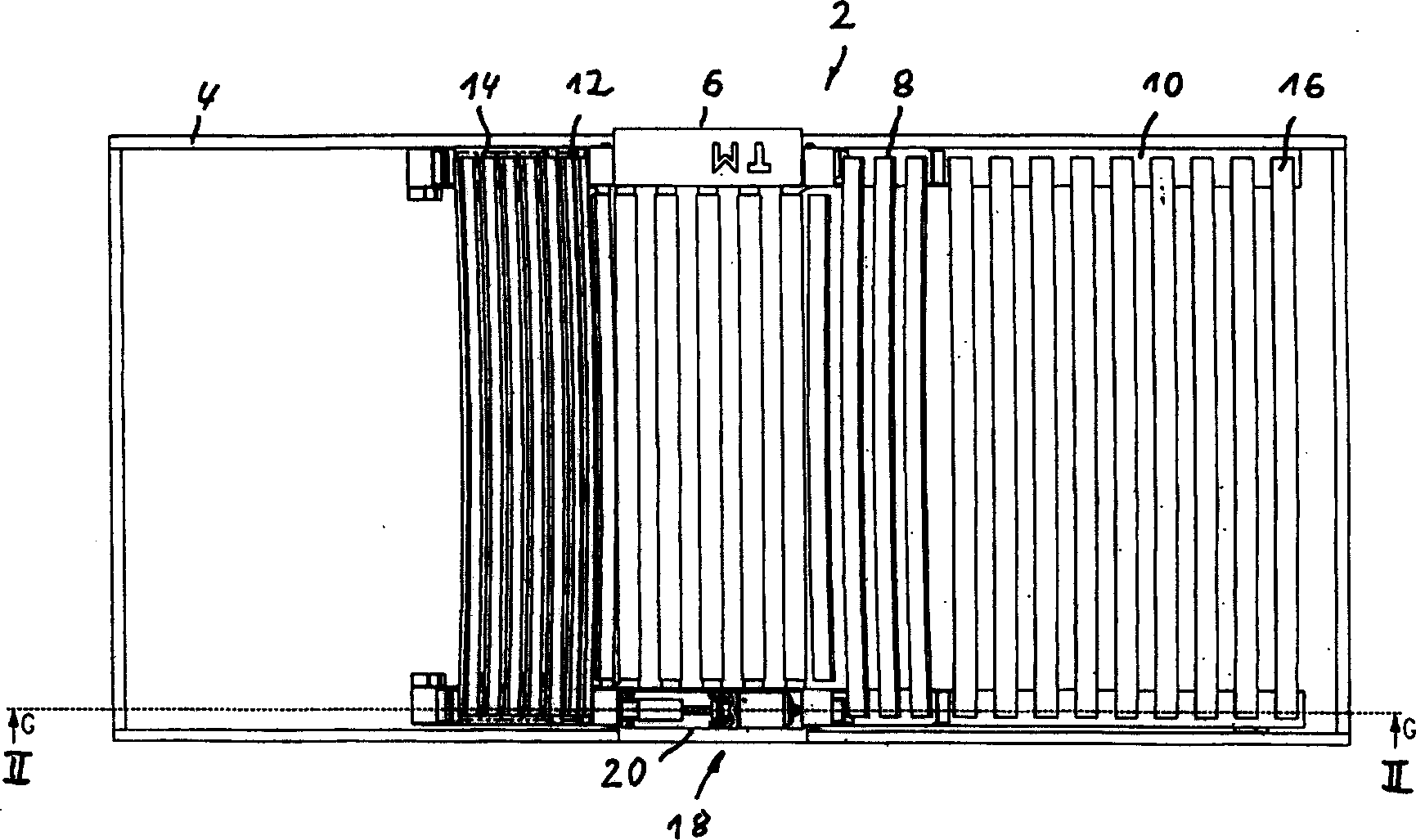

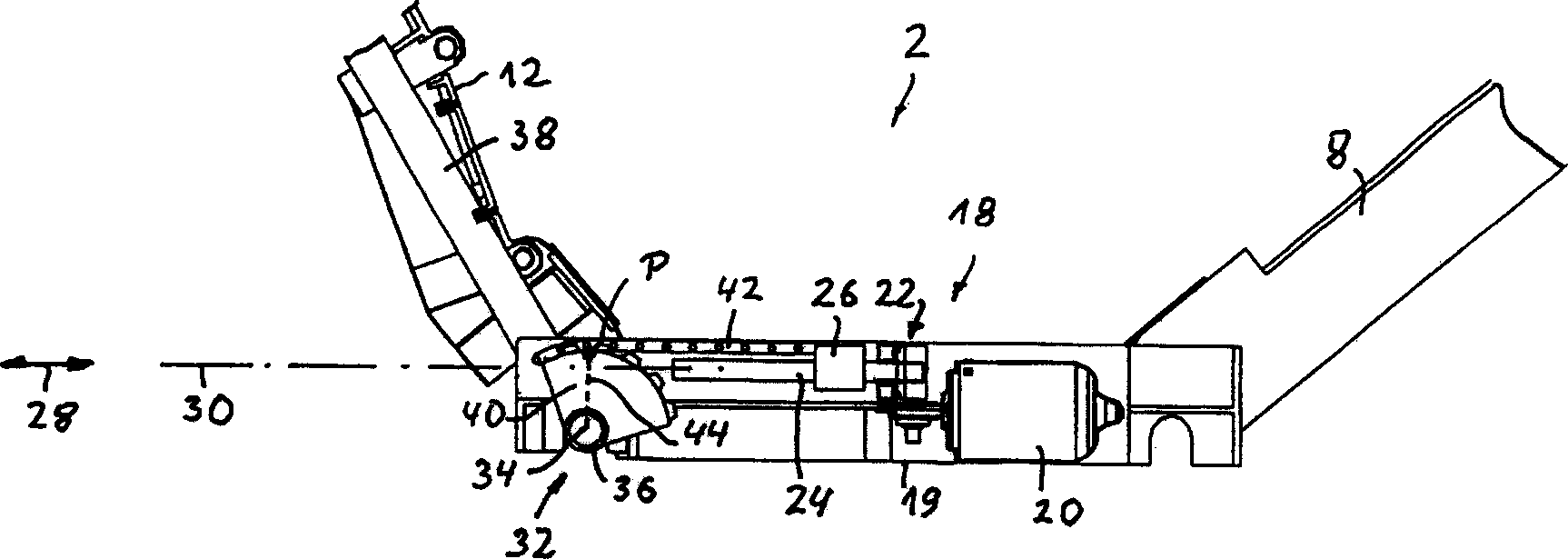

[0036] figure 1To describe an embodiment of the stent device 2 of the present invention. The carrier device 2 according to the exemplary embodiment is designed as a grid of slats and has a frame 4 to which a fixed central support part 6 is connected. A leg support 8 is rotationally connected to the central support 6 about a horizontal axis of rotation. The calf support 10 is connected to the opposite end of the leg support 8 to the middle support 6 in a rotationally flexible manner about a horizontal axis of rotation. An upper body support 12 is connected to the end of the intermediate support 6 opposite to the leg support 8 so as to rotate flexibly about a horizontal axis of rotation. A head support 14 is compliantly connected to the end of the upper body support 12 opposite to the intermediate support 6 so as to rotate about a horizontal axis of rotation. The manner in which the support members 6-14 are connected to each other is generally well known and therefore will no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com