Method and device for suppression of vibration of rotor system with elastic support

A technology of elastic support and suppression band, which is applied in the field of machinery, can solve the problems of dry friction damping and rotor system vibration reduction, and achieve the effect of preventing instability vibration, broad application prospects, and easy control of damping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

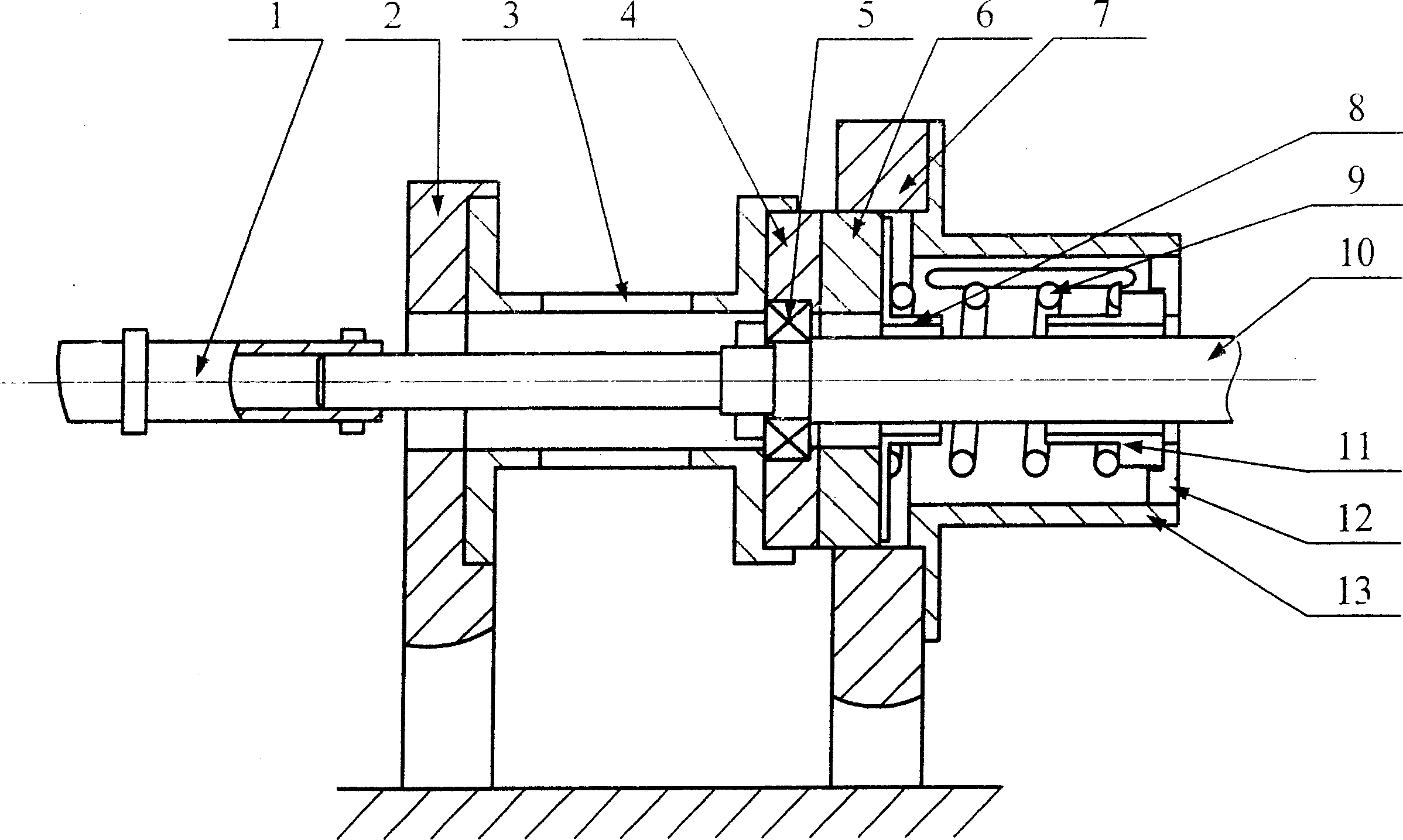

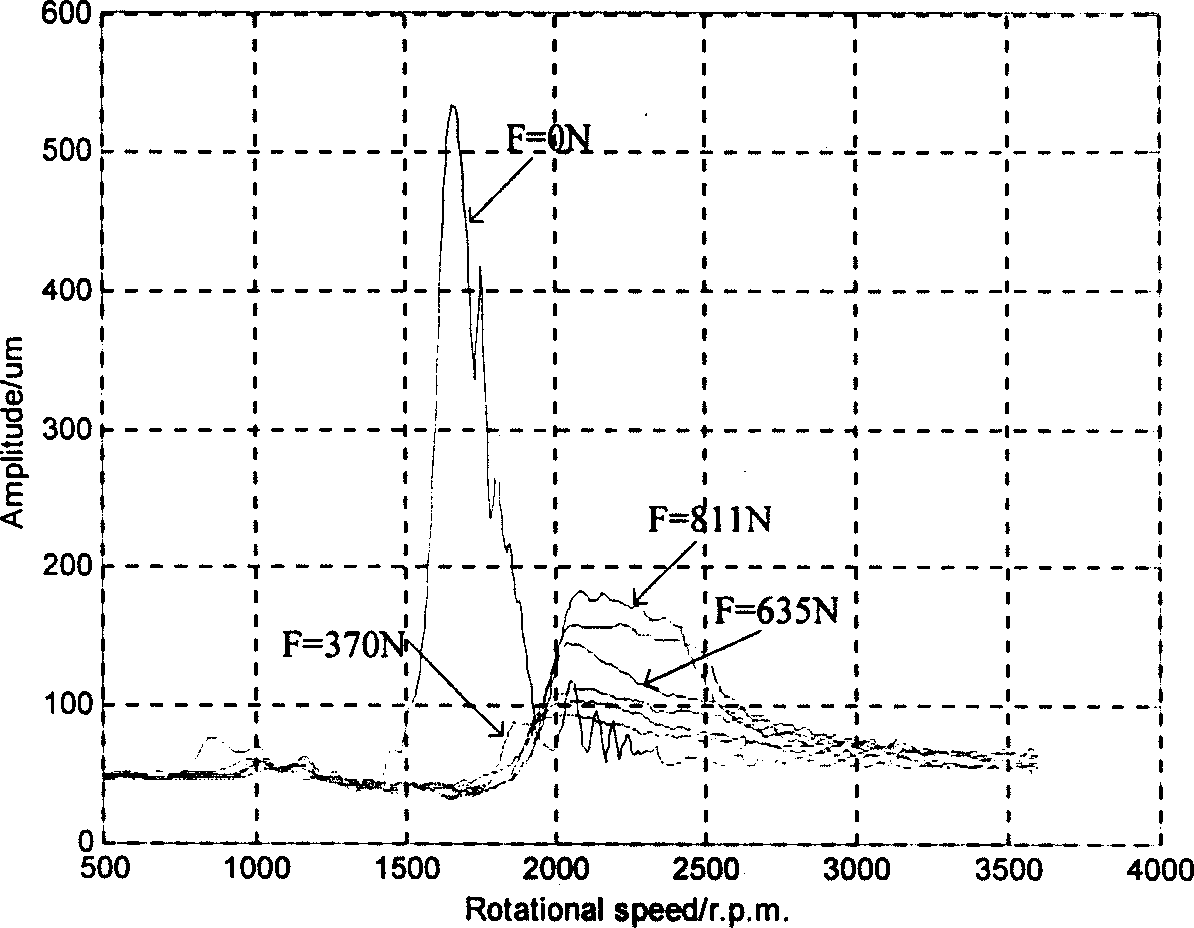

[0018] In this embodiment, external damping caused by dry friction is introduced into the rotor system to reduce the vibration of the rotor system when passing a critical speed and improve the stability of the rotor system.

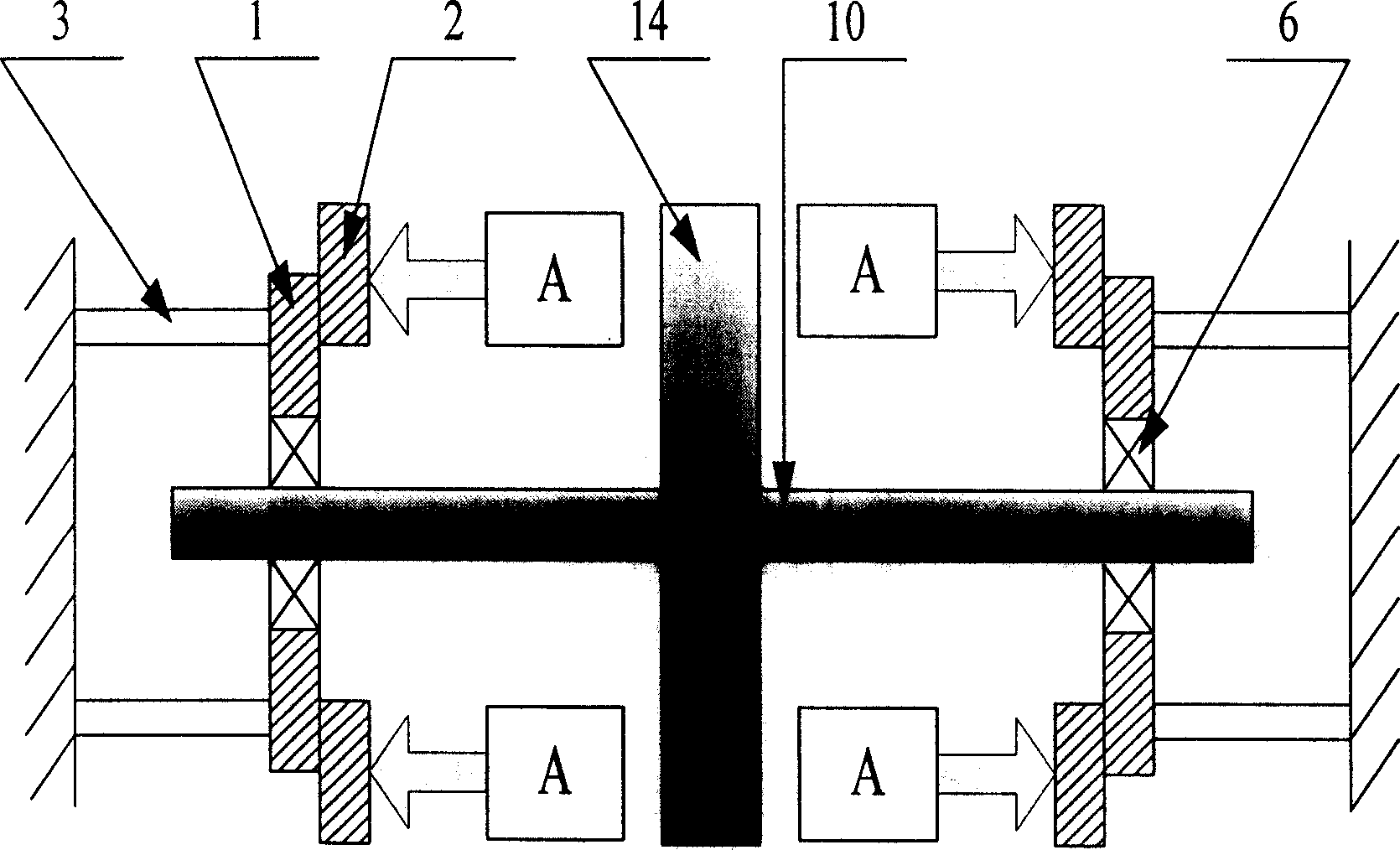

[0019] In this embodiment, according to the structure of the rotor system, a corresponding dry friction damper is designed, and a widely used squirrel-cage elastic support structure is adopted to establish a dry friction damper with a spring as force. In this embodiment, the relative motion between the dynamic and static friction plates in the dry friction damper is used to generate friction to provide external damping to the rotor system. The working method is that when the rotor does not vibrate, the elastic support is in a static state, and the If there is no relative displacement, there will be no friction; when the rotor vibrates, relative displacement will occur between the dynamic friction plate and the static friction plate on the elastic support e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com