Self-locking fastening device

A fastening device and self-locking technology, applied in the direction of locking fasteners, threaded fasteners, washers, etc., can solve the problems of automatic loosening of screws and loss of pre-stretching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

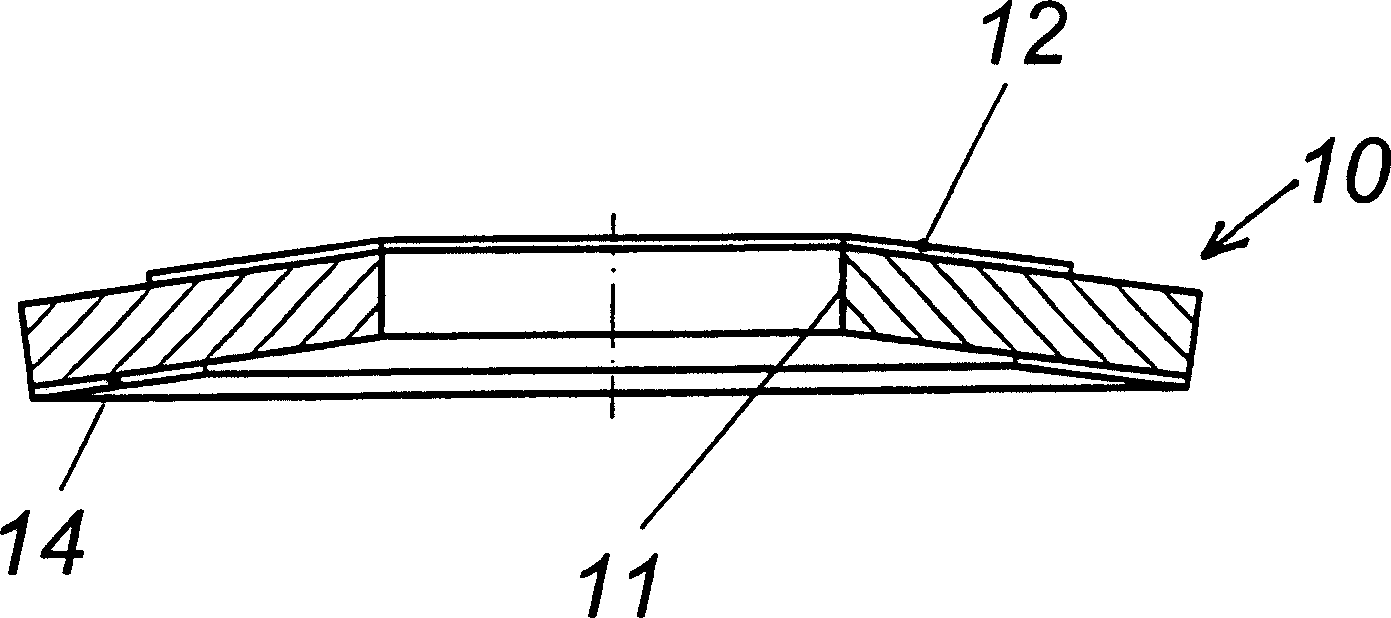

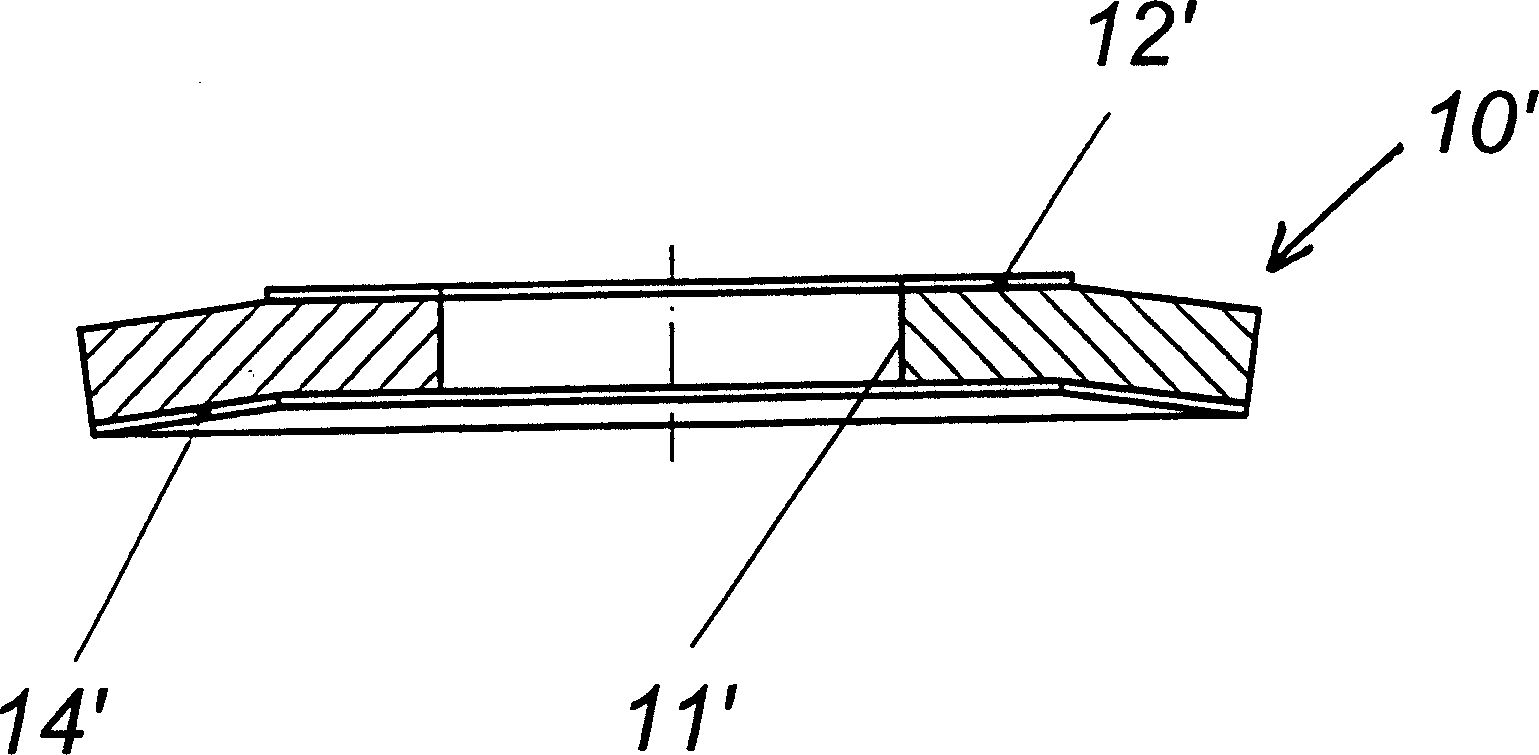

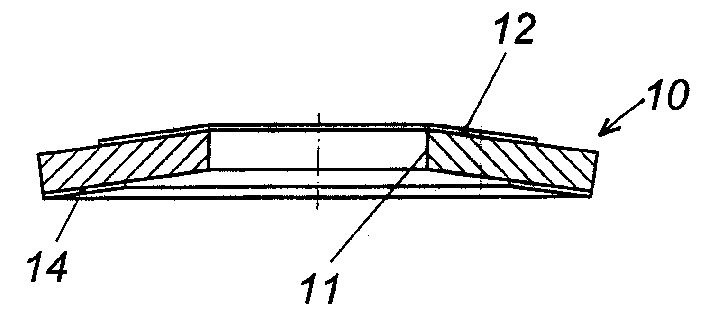

[0015] figure 1 A first embodiment of the washer of the invention for a self-locking fastening device is shown. The gasket 10 has the same shape as a common washer, and has a central hole 11 for allowing threaded bodies (bolts, screws) to pass through. Compared with ordinary gaskets, the gasket according to the present invention is radially arched from the inside to the outside and is made of a material with sufficient elasticity.

[0016] exist figure 1 In this case, the corresponding screw head or nut is located above the washer 10 and the component to be fastened is located below the washer. In this way, the washer 10 is convex in the direction of the screw head or nut and concave in the direction of the assembly. In actual use, towards the top of the washer 10 of the screw head or nut, a suitable reinforcing rib 12 is provided directly near the center hole, and its extension length is about two-thirds of the washer width.

[0017] In the same way, the underside of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com