Grooved forming roll

A forming roll and grooved technology, which is applied in the direction of textiles and papermaking, papermaking, paper machine wet end, etc., can solve the problems of streaks and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

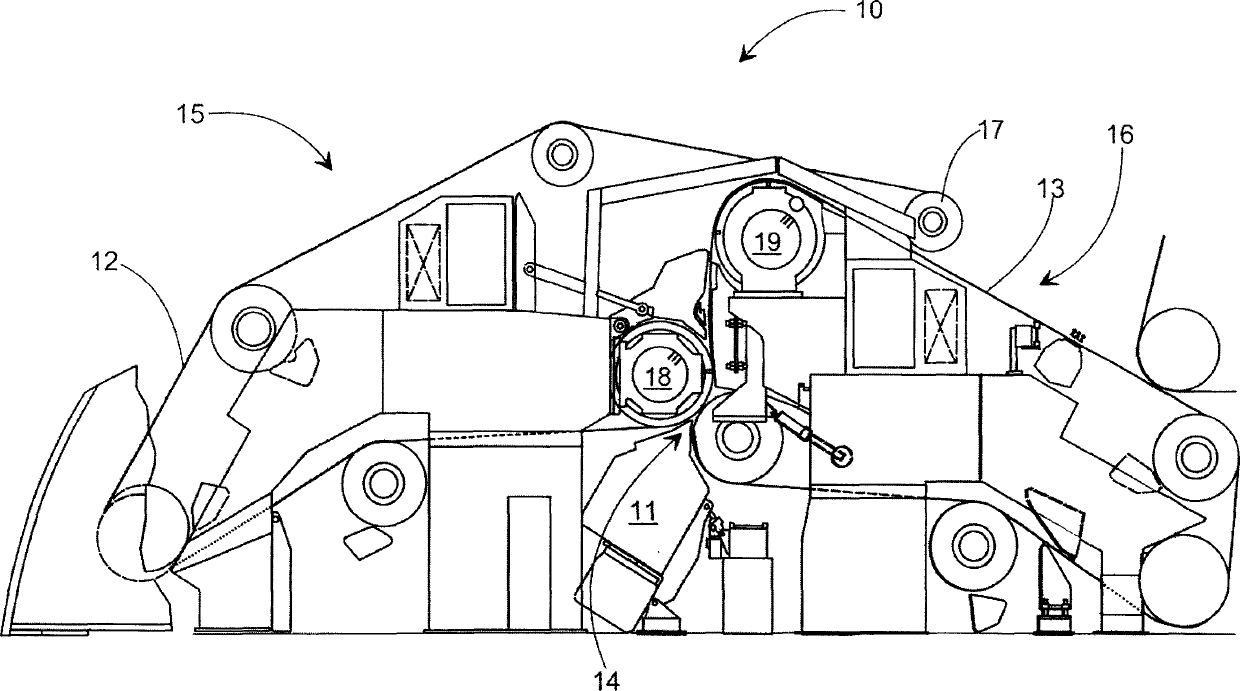

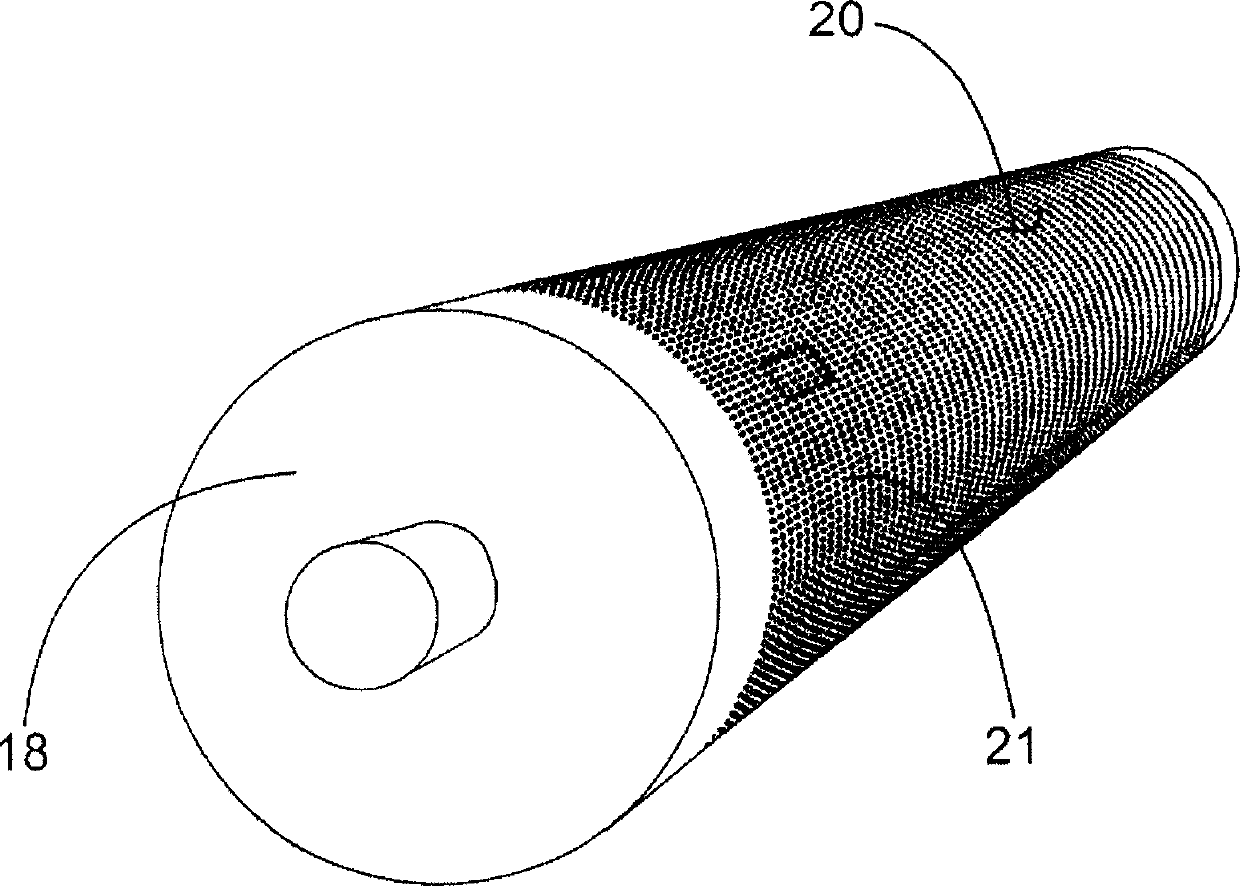

[0018] Figure 1 shows the forming section 10 of a paper machine of known configuration. The forming section 10 is here arranged as a gap former, in which the stock suspension is fed from the headbox 11 to the gap 14 formed by the two fabrics 12 and 13 . The wires 12 and 13 formed into two closed loops are supported in the forming section 10 by aligned roll packs 15 and 16 . In practice, the webs 12 and 13 travel a distance in intimate contact with the web remaining between them. This distance begins at the nip 14 and ends at the return roll 17 of the wire 12 . The return roller 17 is supported above the inner wire 13 . This roll pack 15 of the outer wire also includes a forming roll 18 shared between the roll packs 15 and 16, starting from the nip 14 . This forming roll is also referred to as the first couch roll. The second couch roll 19 is also shared between the roll assembly parts 15 and 16 .

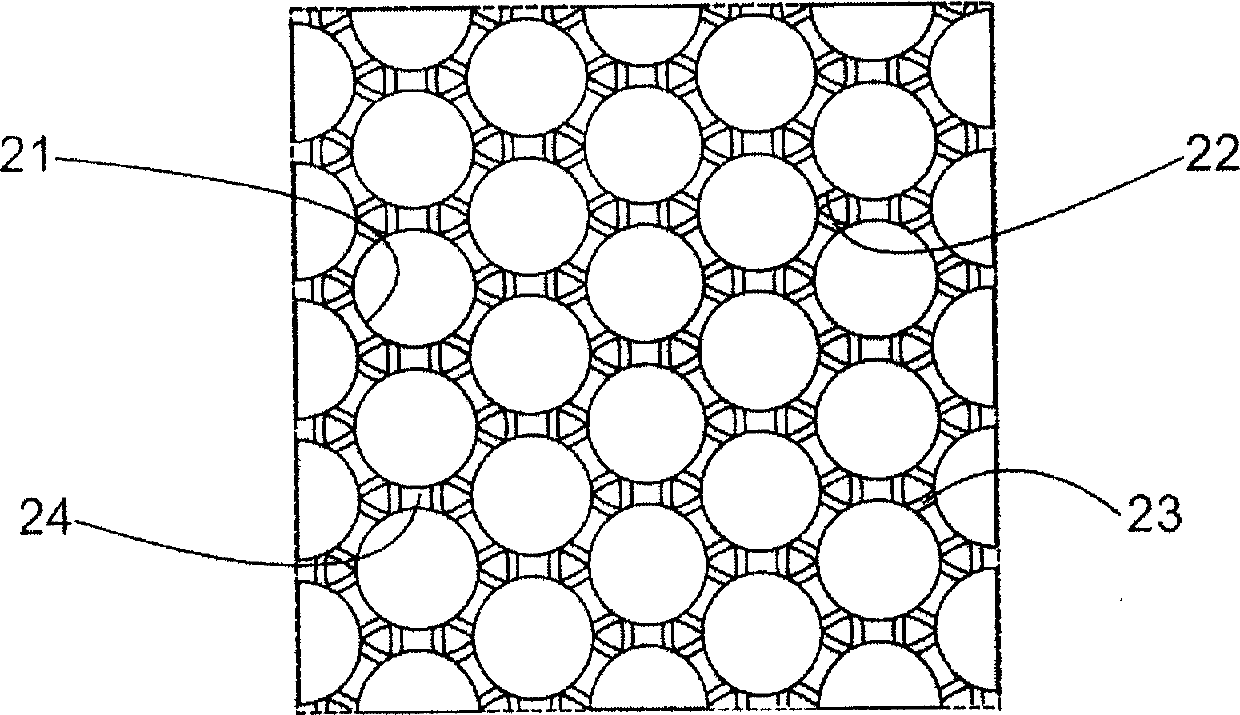

[0019] The forming rolls according to the invention are used in the formin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com