A scrub press type garlic flakes separating machine

A splitting machine and splitting technology, which is applied in the fields of vegetable or fruit peeling, food science, application, etc., can solve the problems of difficulty in forming scale effect, large destructiveness of garlic, labor and time-consuming, etc., and achieve simple and reasonable structure, The effect of fast processing speed and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

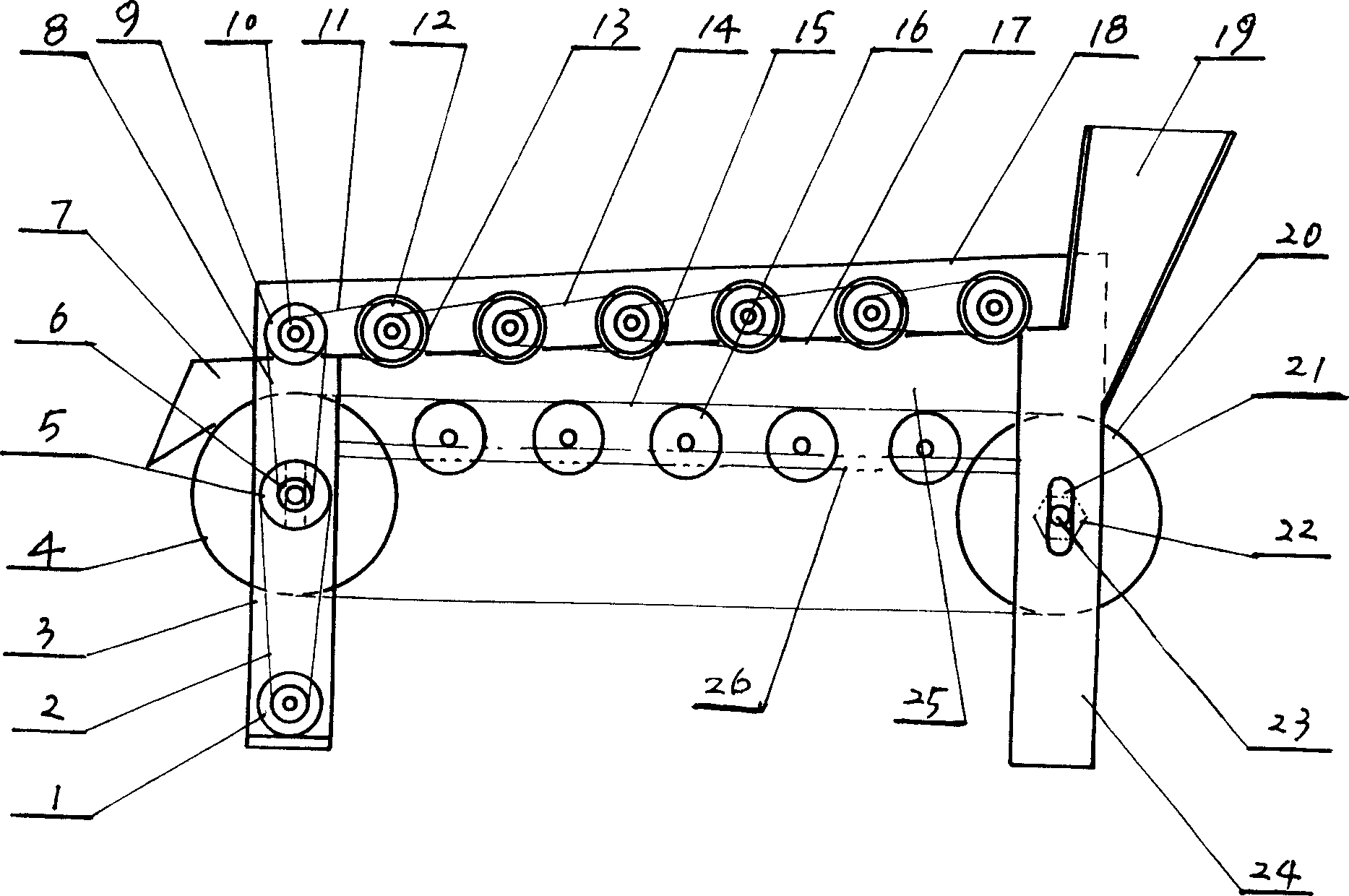

[0009] In the figure, the vertical support (3), (24) is two pairs of stands and mutually parallel supports, and the vertical support (24) is higher than the vertical support (3), so that the upper support (18) that is fixedly connected has a leftward The angle of inclination also makes the right side of the rubbing passage (25) tall and large, and the left side is low.

[0010] In the figure, rubbing and pressing conveyer belt (15) is the closed wide band that rubber-plastic material is made, and its frictional force is not only very big, and has good soft elasticity in addition, both can rub and press garlic and make it split, It will not make it broken and damaged.

[0011] In the figure, the rubbing roller (13) is a cylinder, and its corresponding parallel installation is above the middle of the two guide wheels (16), and its just corresponding below is the rubbing conveyor belt (15), which can make the garlic have A resilient cushion.

[0012] In the figure, the power of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com