Pneumatic toggle type battery plastic cover pressing method

A technology of pneumatic toggle lever and plastic cover, which is applied in the direction of battery pack parts, circuits, electrical components, etc., can solve the problems of high maintenance cost, high power consumption of the device, and large maintenance volume, and achieve reduced maintenance cost and good stability , The effect of maintenance reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

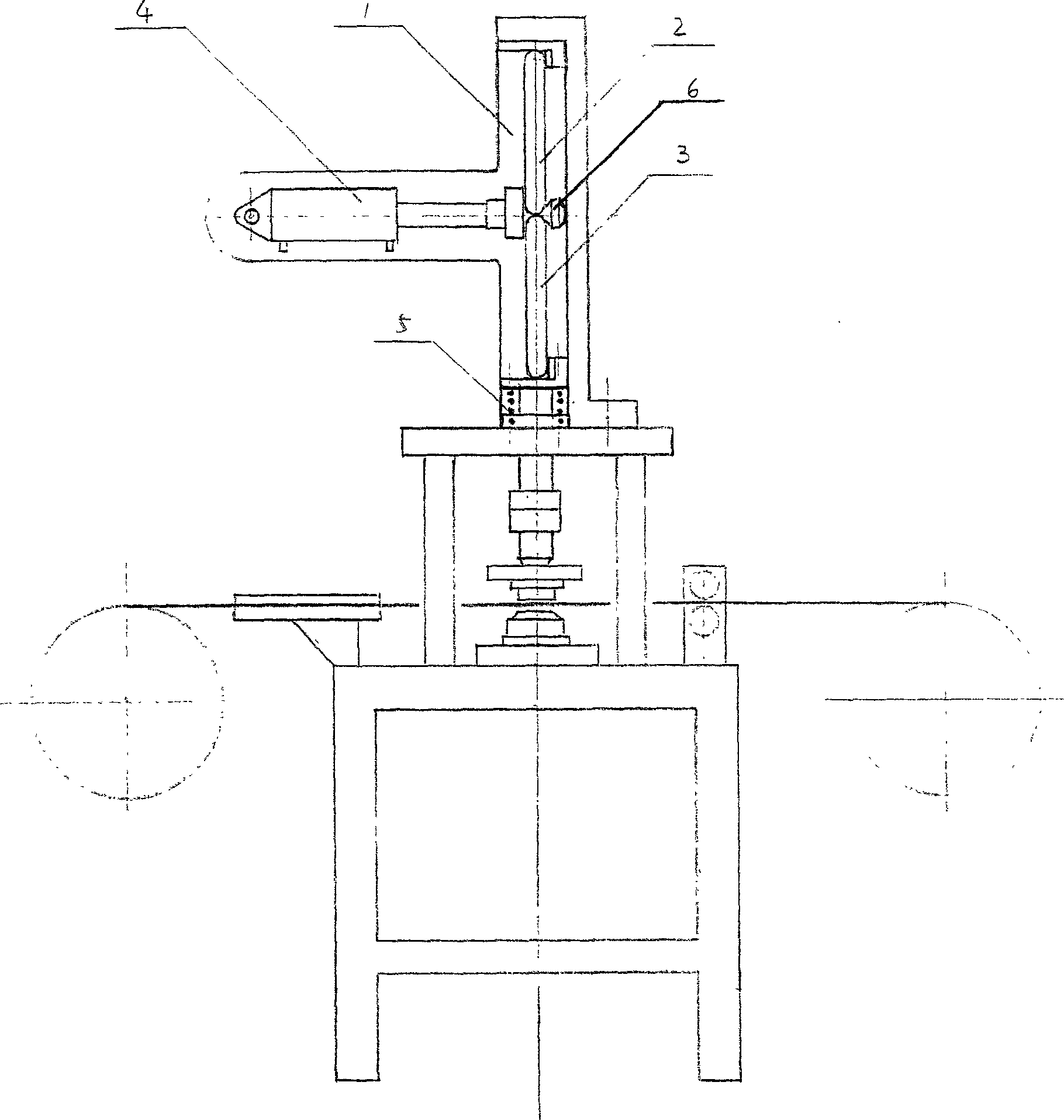

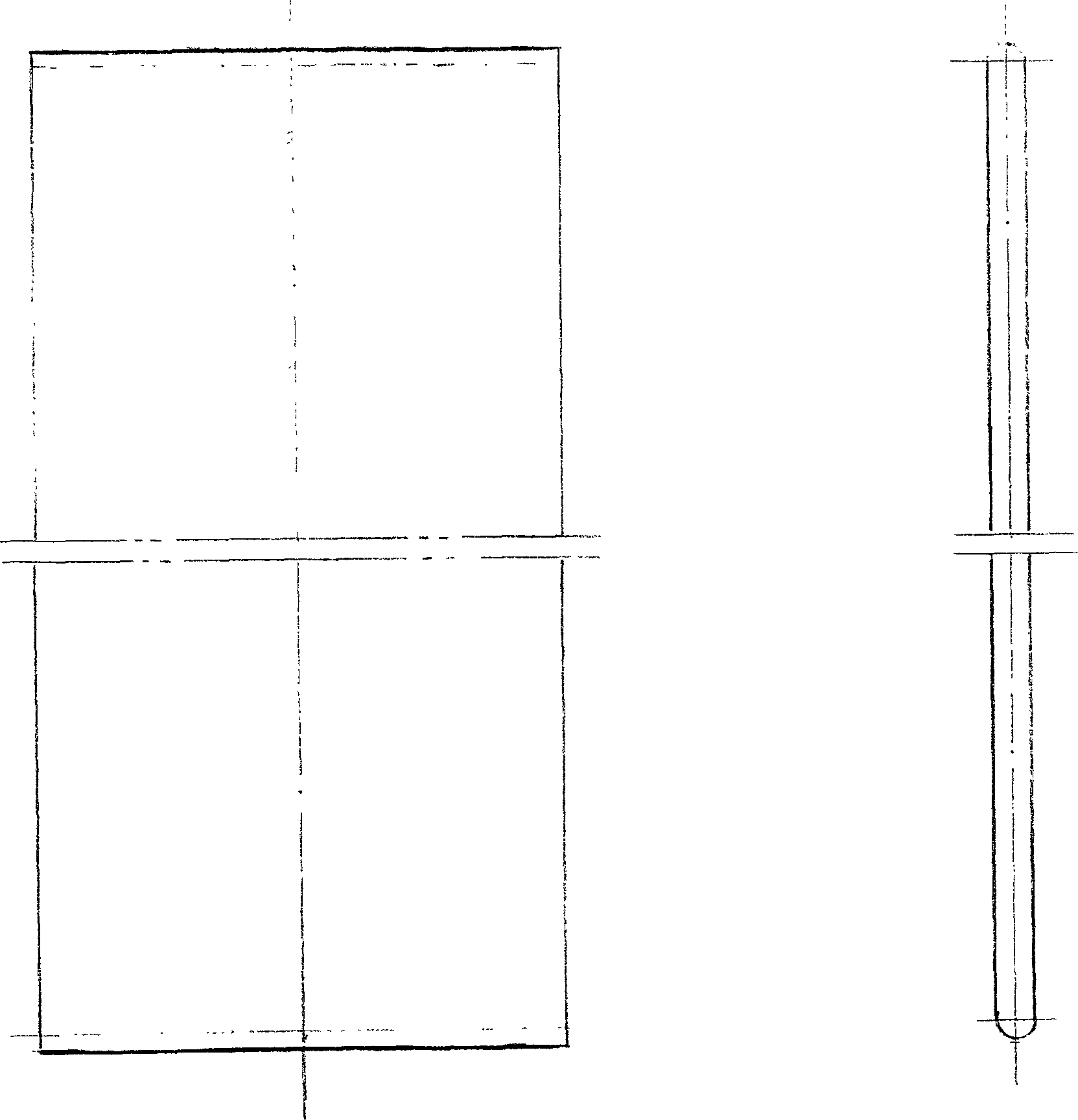

[0022] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

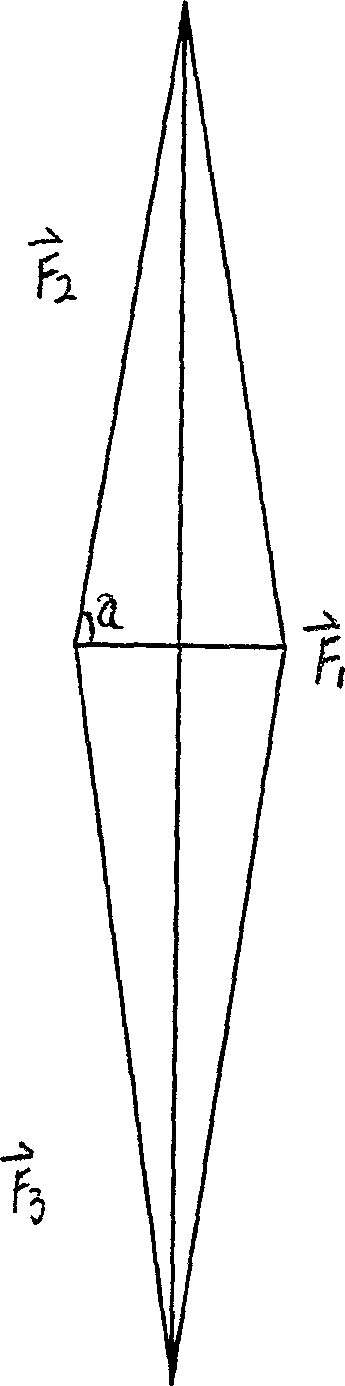

[0023] figure 1 , figure 2 Among them, in order to ensure the stability of the toggle in the swing process, the present invention widens the toggle to a plate structure. Due to the widening of the toggle, the stress surface is lengthened and the pressure intensity is reduced. In addition, at both ends of the length direction processed into a circular arc, such as figure 2 , allow it to roll on the force-bearing surface to reduce friction, so that the toggle lever (2), (3) hardly has other external force losses during the force-bearing process. Because all adopt the rolling high-paying contact, so in the process of pressing and unclamping, the relative force-bearing surfaces can not be separated, and the spring (5) is adopted to make it reset without affecting the kinematic relationship. Another positioning stop block (6) is provided to p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com