Pluggable electronic module and receptacle with heat sink

A technology of electronic modules and heat sinks, applied in the direction of component plug-in combination, electrical components, electrical equipment structural parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

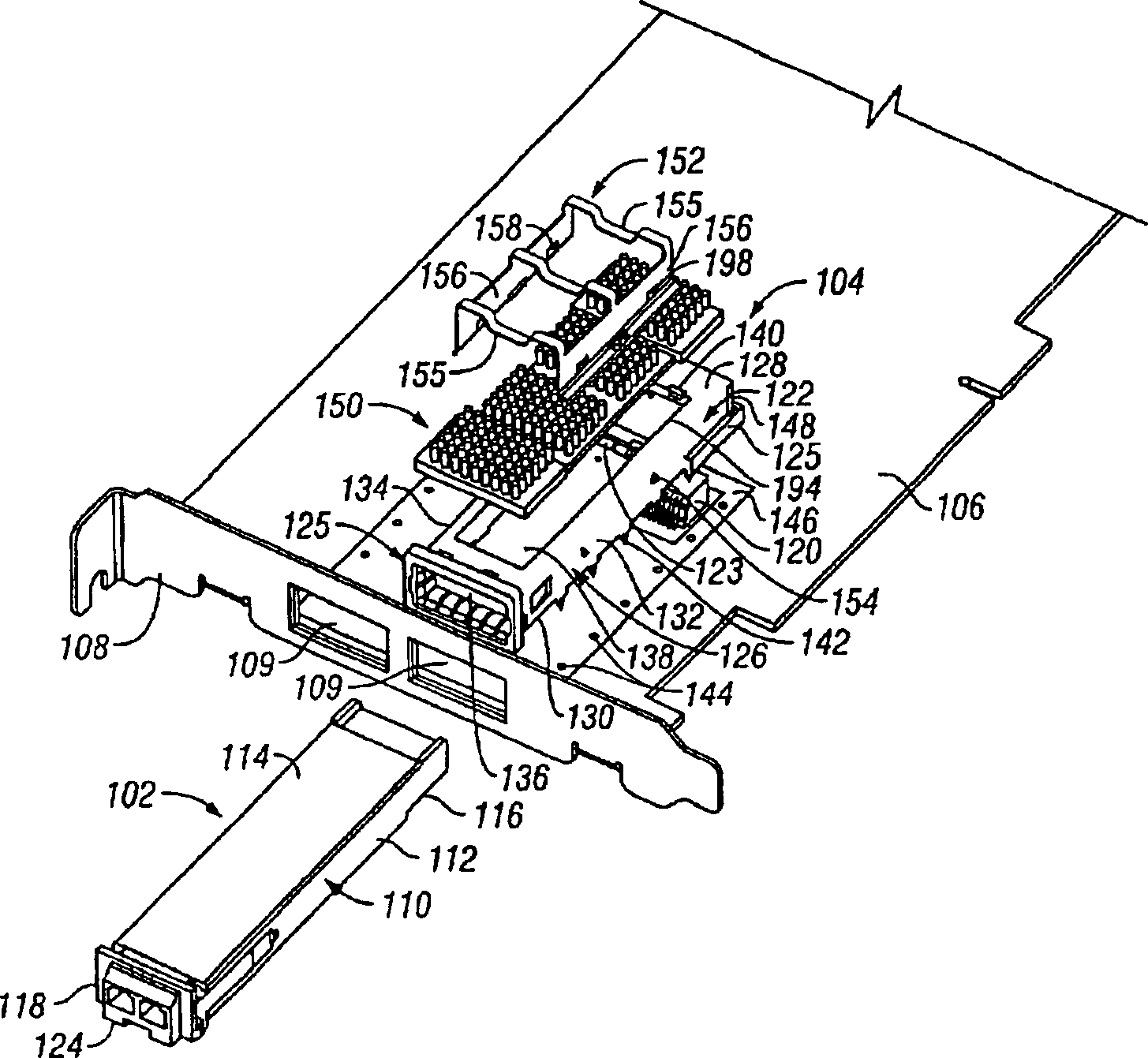

[0032] figure 1 A module assembly and socket assembly 100 formed in accordance with an example embodiment of the invention is shown. Assembly 100 also serves to address heat dissipation and electromagnetic shielding of components transmitting data signals at high speeds (eg, data transfer rates of 10 gigabits per second, Gbs), for reasons detailed below. However, it should be understood that the benefits and advantages of the present invention are equally applicable to other data transfer rates and various systems and standards. Thus, although the present invention has been described and shown in the context of assembly 100, the present invention is not limited to assembly 100, and thus, assembly 100 is used for purposes of illustration and not limitation.

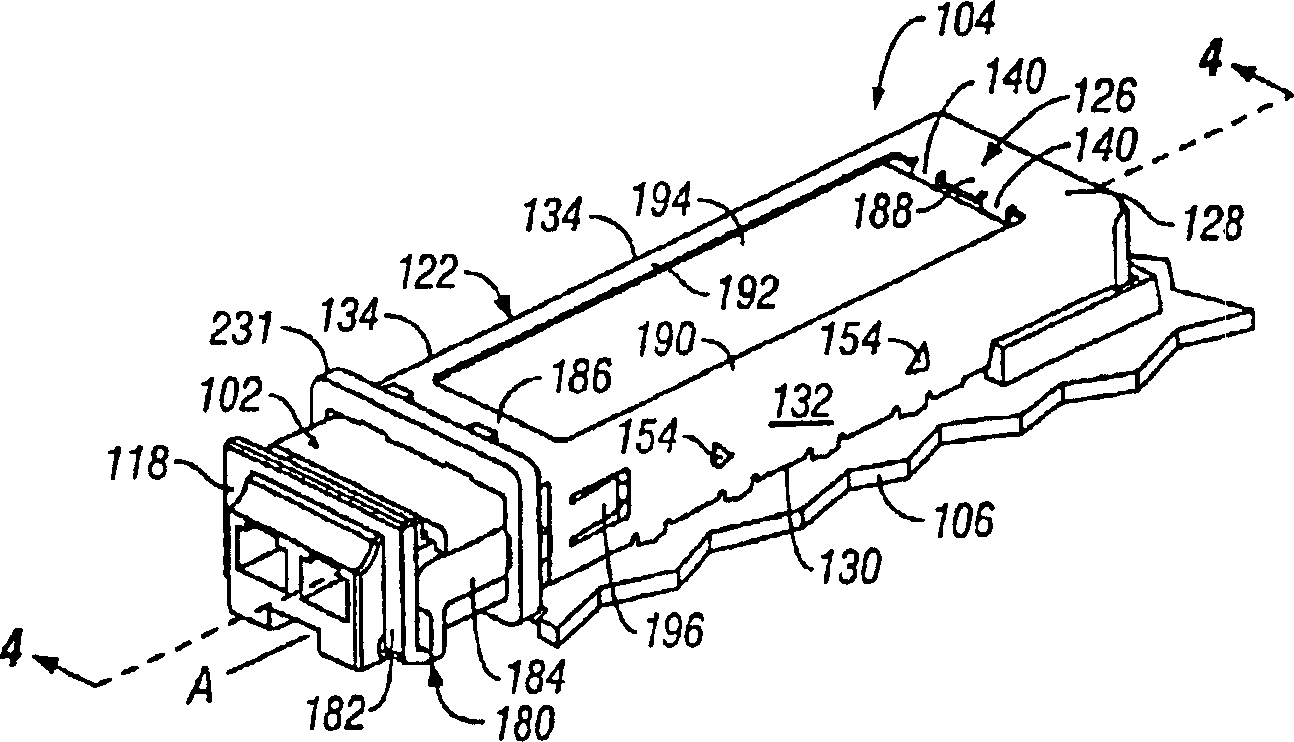

[0033] Such as figure 1 As shown, the assembly 100 generally includes a modular assembly 102 configured to be inserted into a socket assembly 104 mounted on a host circuit board 106 mounted on a host system such as a rou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com