Pre-forming device in hollow structure high-pressure forming process

A technology of internal high pressure forming and hollow structure, which is applied in the direction of forming tools, metal processing equipment, manufacturing tools, etc., and can solve the problems of large section deformation, flash defects, and waste products in local areas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

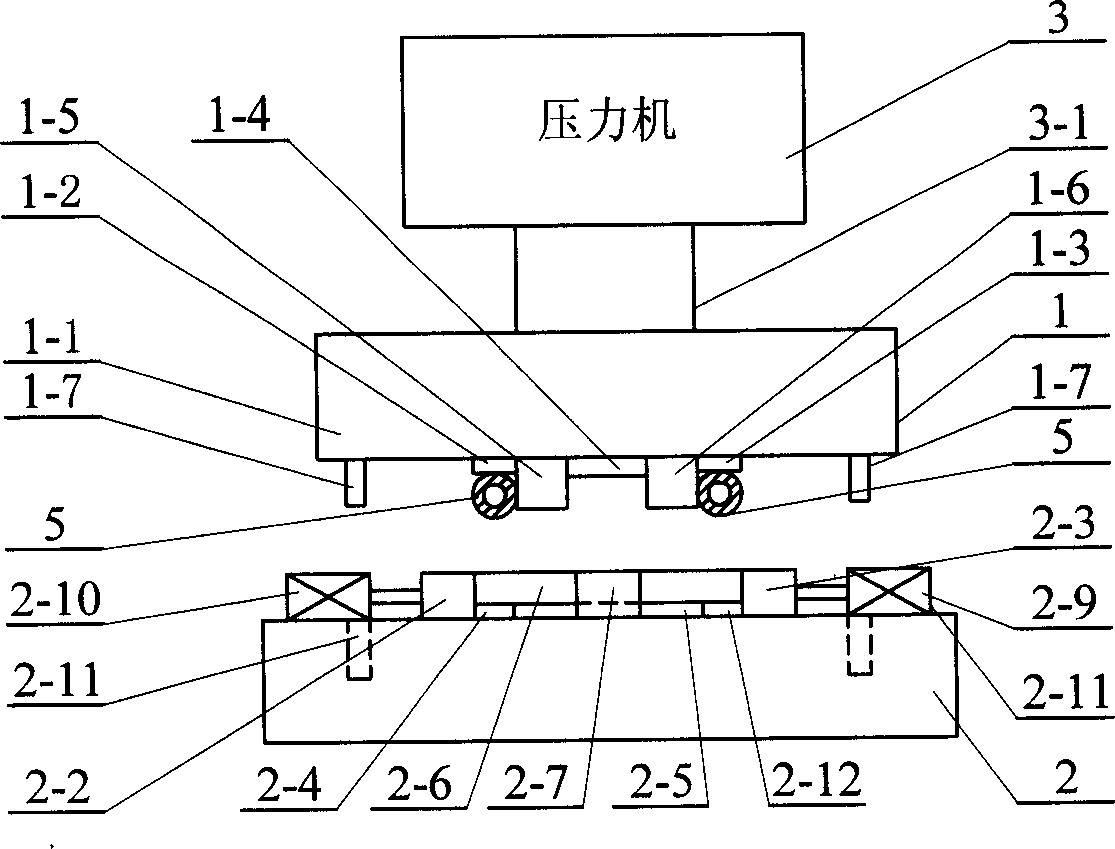

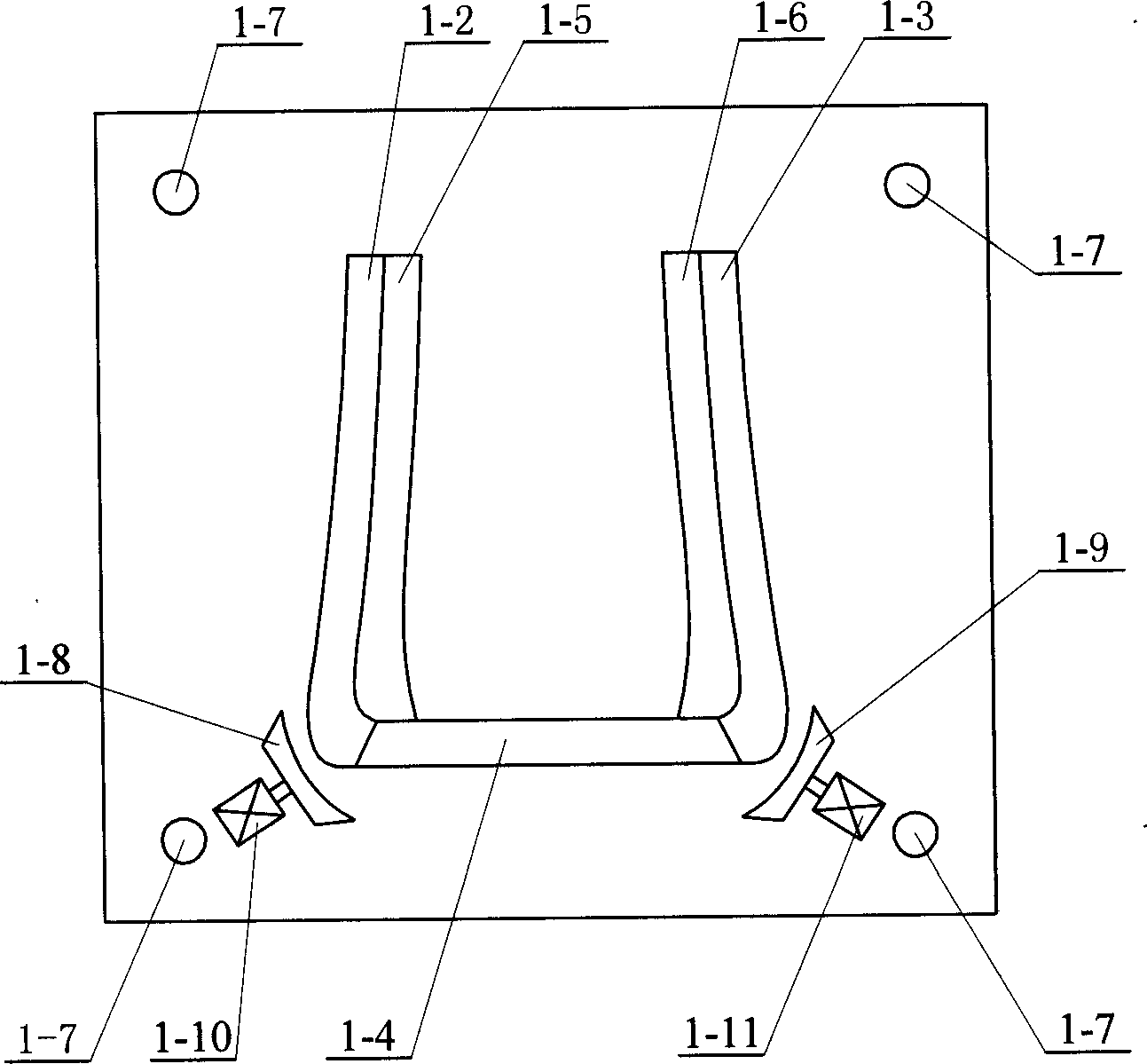

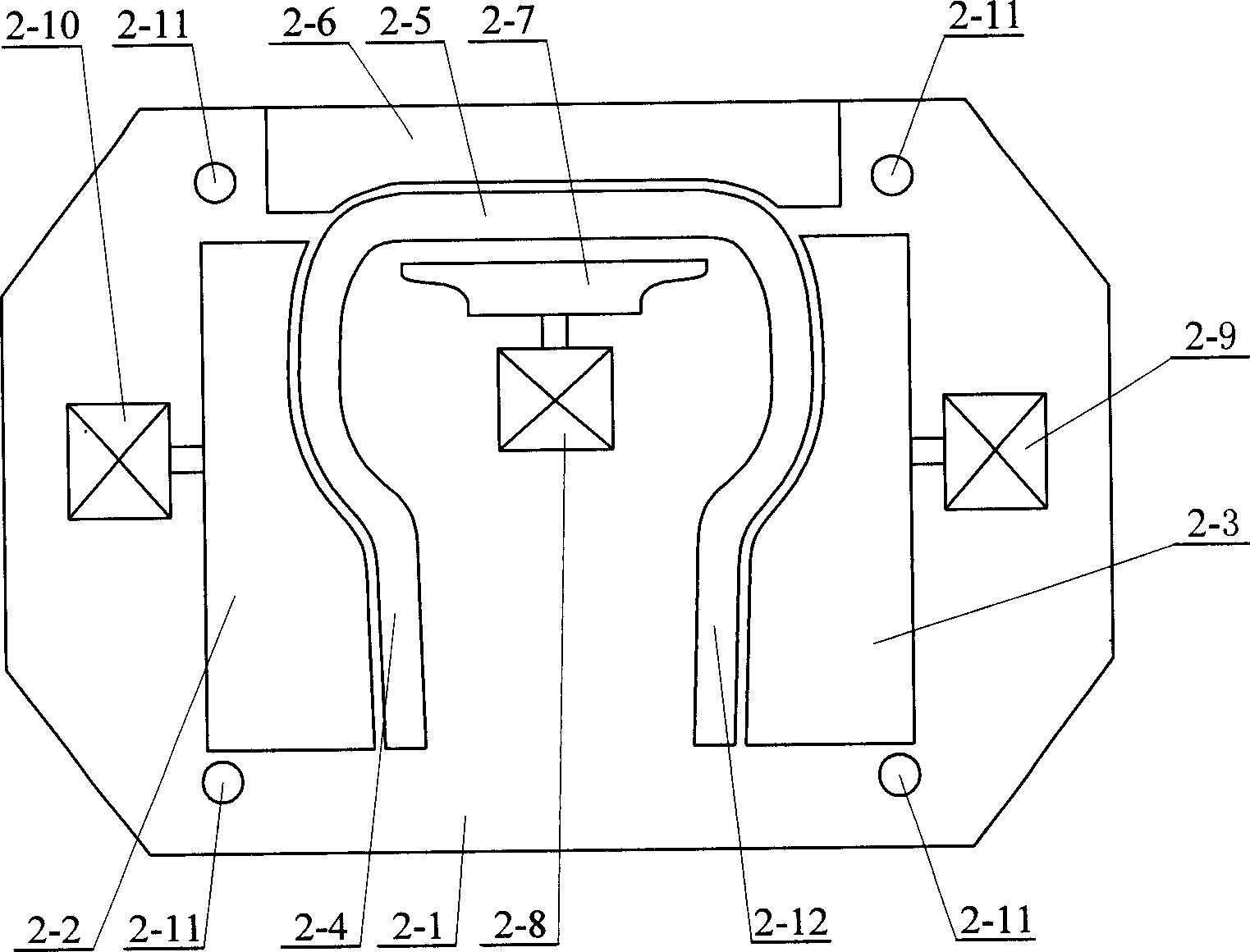

[0005] Specific implementation mode one: the following combination Figure 1 to Figure 6 This embodiment will be specifically described. It consists of an upper die 1, a lower die 2 and a press 3. The upper top surface of the upper die 1 is fixedly connected to the lower end of the pressure head 3-1 of the press 3. The lower die 2 is arranged below the upper die 1. The upper die 1 Consists of the upper mold bottom plate 1-1, the upper module of the left arm 1-2, the upper module of the right arm 1-3, the upper module of the forearm 1-4, the upper inner module of the left arm 1-5, and the upper inner module of the right arm 1- 6 and guide columns 1-7, the elongated left-arm upper-side inner module 1-5 and right-arm upper-side inner module 1-6 are respectively distributed on the left half of the lower surface of the upper mold bottom plate 1-1 in the front and rear direction And on the right half, the module 1-2 on the left arm is fixed on the lower surface of the upper mold bo...

specific Embodiment approach 2

[0006] Specific implementation mode two: the following combination figure 2 This embodiment will be specifically described. The difference between this embodiment and Embodiment 1 is that it also includes a left corner sliding module 1-8, a right corner sliding module 1-9, No. 8 is arranged on the left front side of the connection between the left arm upper module 1-2 and the forearm upper module 1-4, and the left corner sliding module 1-8 is connected to the No. 4 oil cylinder 1-10 fixed on the lower surface of the upper mold bottom plate 1-1 On the piston rod, the right corner sliding module 1-9 is arranged on the right front side of the connection between the right arm upper module 1-3 and the forearm upper module 1-4, and the right corner sliding module 1-9 is connected under the bottom plate 1-1 fixed on the upper mold On the piston rod of No. 5 oil cylinder 1-11 on the surface. Such setting is beneficial to the forming of the tube blank 5 at the corner. Other composi...

specific Embodiment approach 3

[0007] Specific implementation mode three: the following combination Figure 4 to Figure 6 This embodiment will be specifically described. The difference between this embodiment and Embodiment 1 is that the cross-sectional shapes of the first cavity 6 , the second cavity 7 and the third cavity 8 are rectangular, square, trapezoidal, elliptical, polygonal, or curved. In this embodiment, cavities with various cross-sectional shapes are formed by changing the shapes of the upper, lower, left, and right surfaces participating in the molding, thereby completing the pre-forming of pipes with various cross-sectional shapes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com