Device for cleaning water quality sensors

A sensor, oxygen sensor technology, applied in measuring devices, instruments, testing water, etc., can solve problems such as inappropriate sensors, and achieve the effect of increasing costs, prolonging configuration time, and saving time and money

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

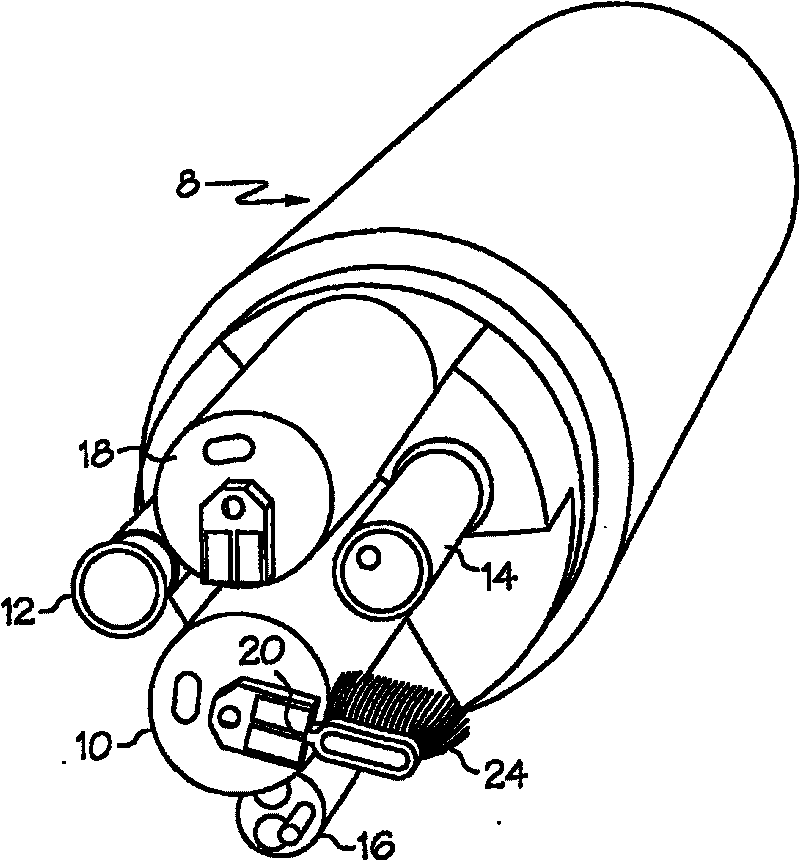

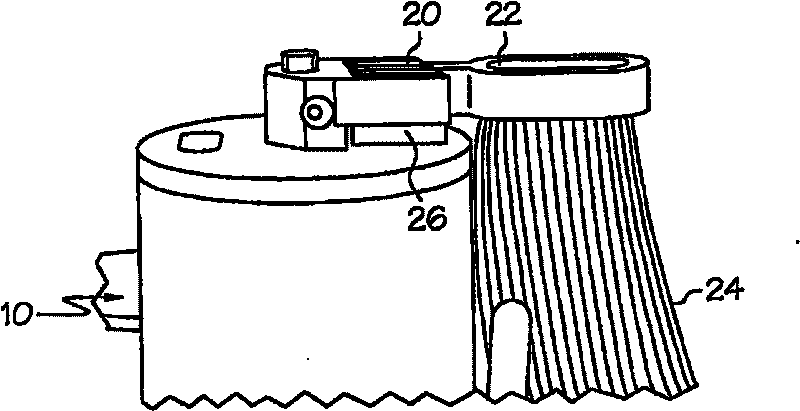

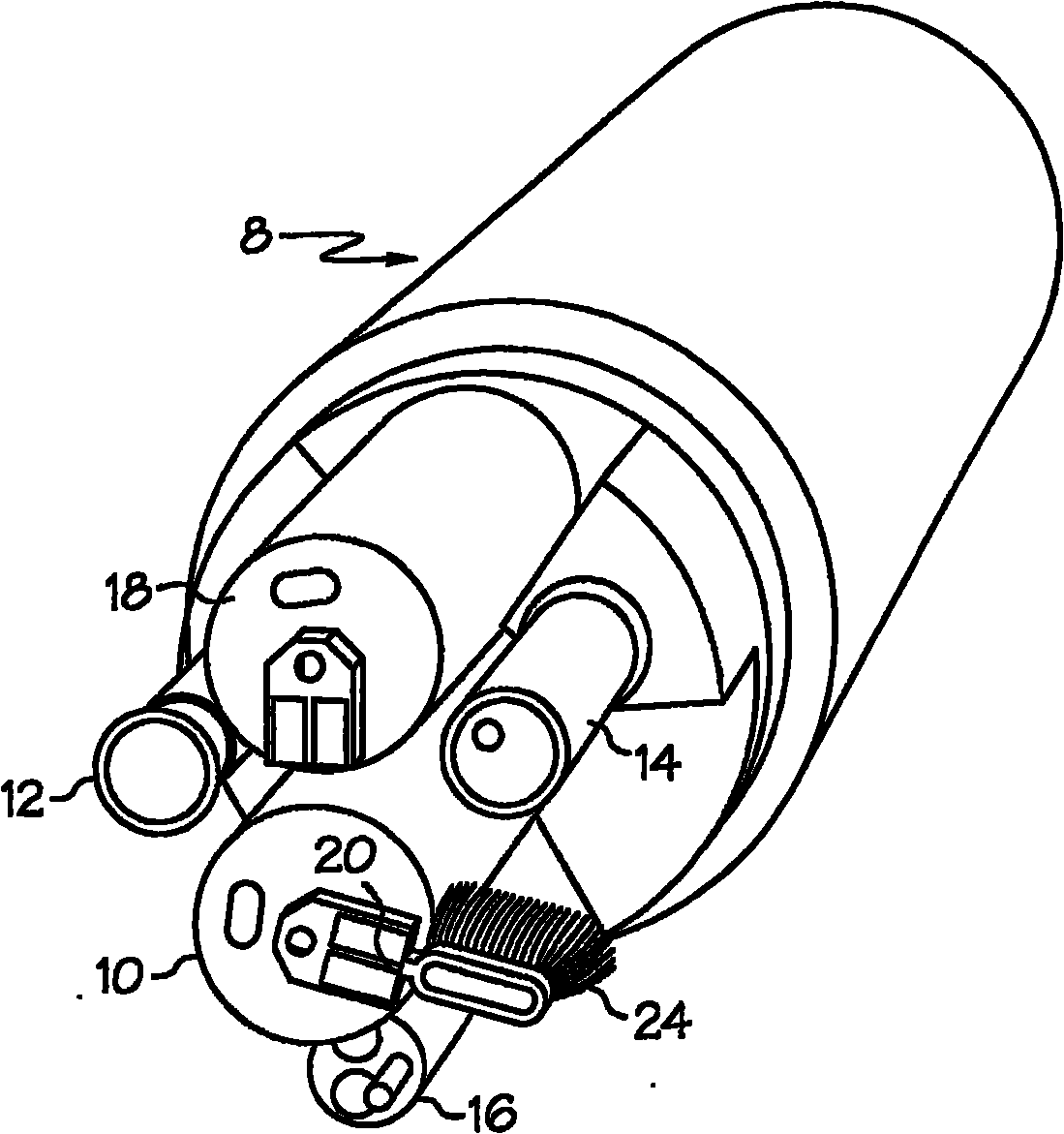

[0012] figure 1 is an example of a detector according to the invention. This detector is available now from YSI as the model YSI 6600EDS. This detector 8 includes: a turbidity sensor 10 for measuring turbidity as a function of back reflection; a dissolved oxygen sensor 12 for measuring dissolved oxygen as a function of polarographic current; A pH and redox potential sensor 14 for pH and redox potential; a temperature and conductivity sensor 16 and a sensor 18 which may be a chlorophyll or a basilisk sensor. according to figure 2 In the illustrated invention, the wiping element 20 has a central arm 22 surrounded by a wiping medium 26, such as a foam rubber wiping sheet. A brush 24 is mounted on the portion of the arm 22 that extends beyond the diameter of the turbidity sensor 10 . The brush is long enough to wipe the other sensors of the detector to prevent dirt buildup and increased bristles.

[0013] According to a preferred embodiment of the present invention, the bris...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com