Damper-free support system for modular high temperature air-cooled pile pressure casing

A high-temperature gas-cooled reactor and support system technology, applied in the direction of reducing greenhouse gases, reactors, and climate sustainability, can solve problems such as endangering the safety of pressure boundaries, excessive compressive stress or tensile stress, and easy failure of dampers. To achieve the effect of flexible rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings.

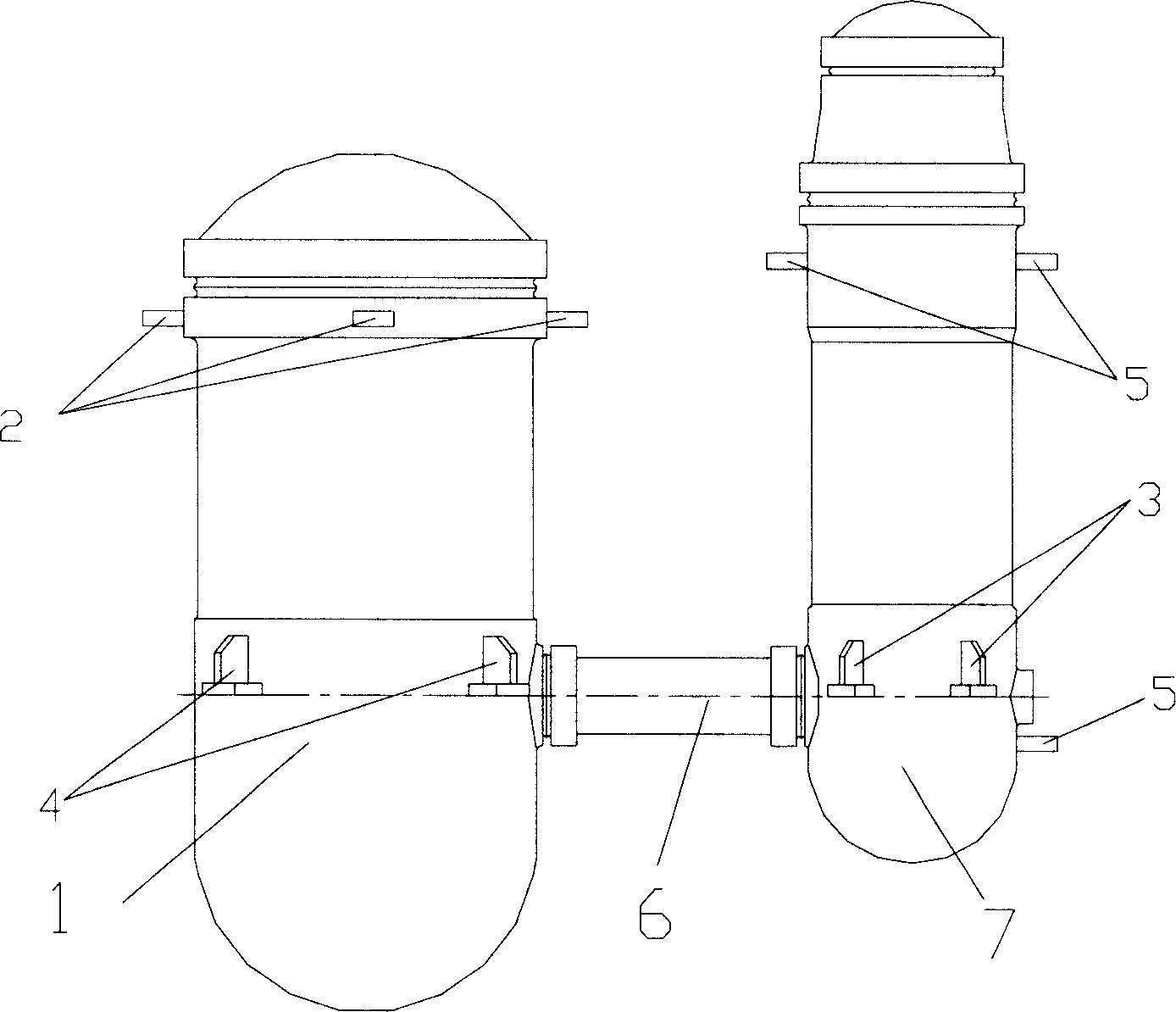

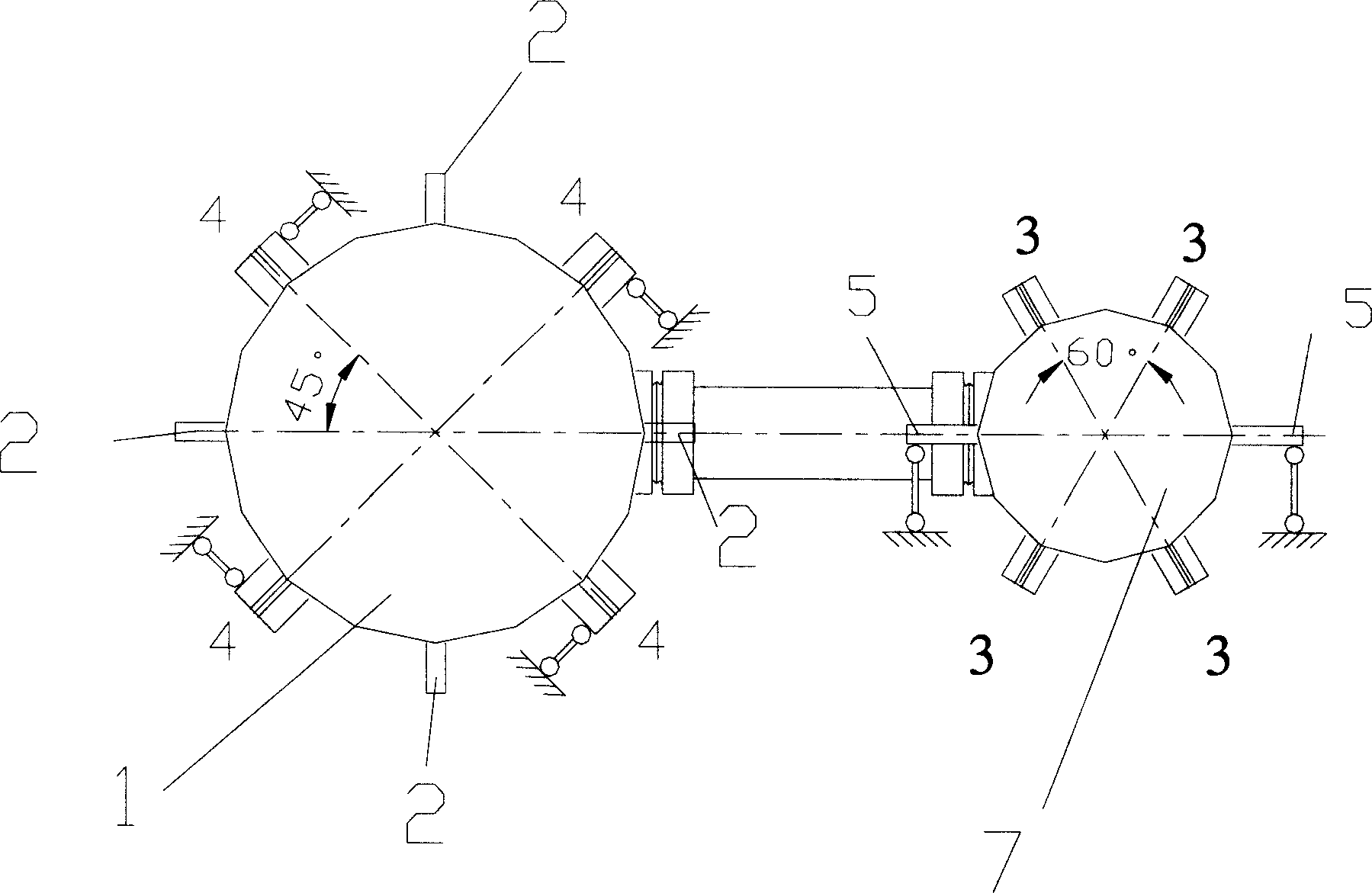

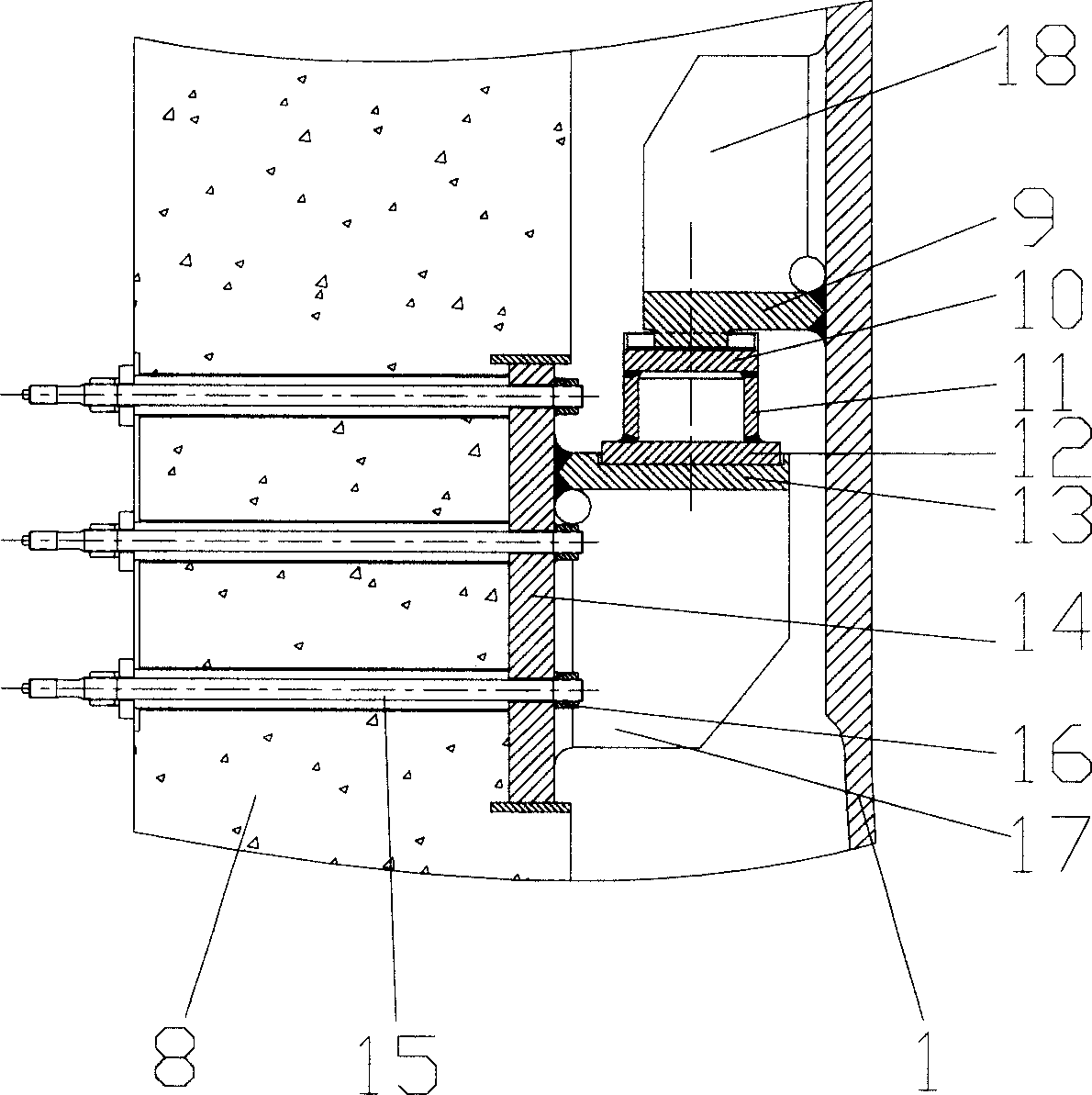

[0032] The modular high-temperature gas-cooled reactor pressure vessel of the present invention includes a reactor pressure vessel 1 and a steam generator pressure vessel 7 connected to each other through a hot gas conduit 6 . The damper-free support system of the modular high-temperature gas-cooled reactor pressure vessel of the present invention includes the first main load-bearing support 4 connecting the reactor pressure vessel 1 and the biological shielding layer 8 arranged on the height of the hot gas conduit 6 axis, in order to prevent the reactor The pressure shell 1 rotates and axially displaces; the second main load-bearing support 3 connecting the pressure shell of the steam generator 7 and the biological shielding layer 8 arranged at the height of the axis of the hot gas conduit 6 is used to prevent the pressure shell 7 of the steam generator from Displac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com