Connection structure of side member to cross member

A technology for connecting structures and side members, applied in the directions of upper structure, lower structure, and upper structure sub-assembly, etc., can solve the problems of increasing the weight and complexity of the structure, increasing the number and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] An embodiment of the present invention will be described below with reference to the accompanying drawings.

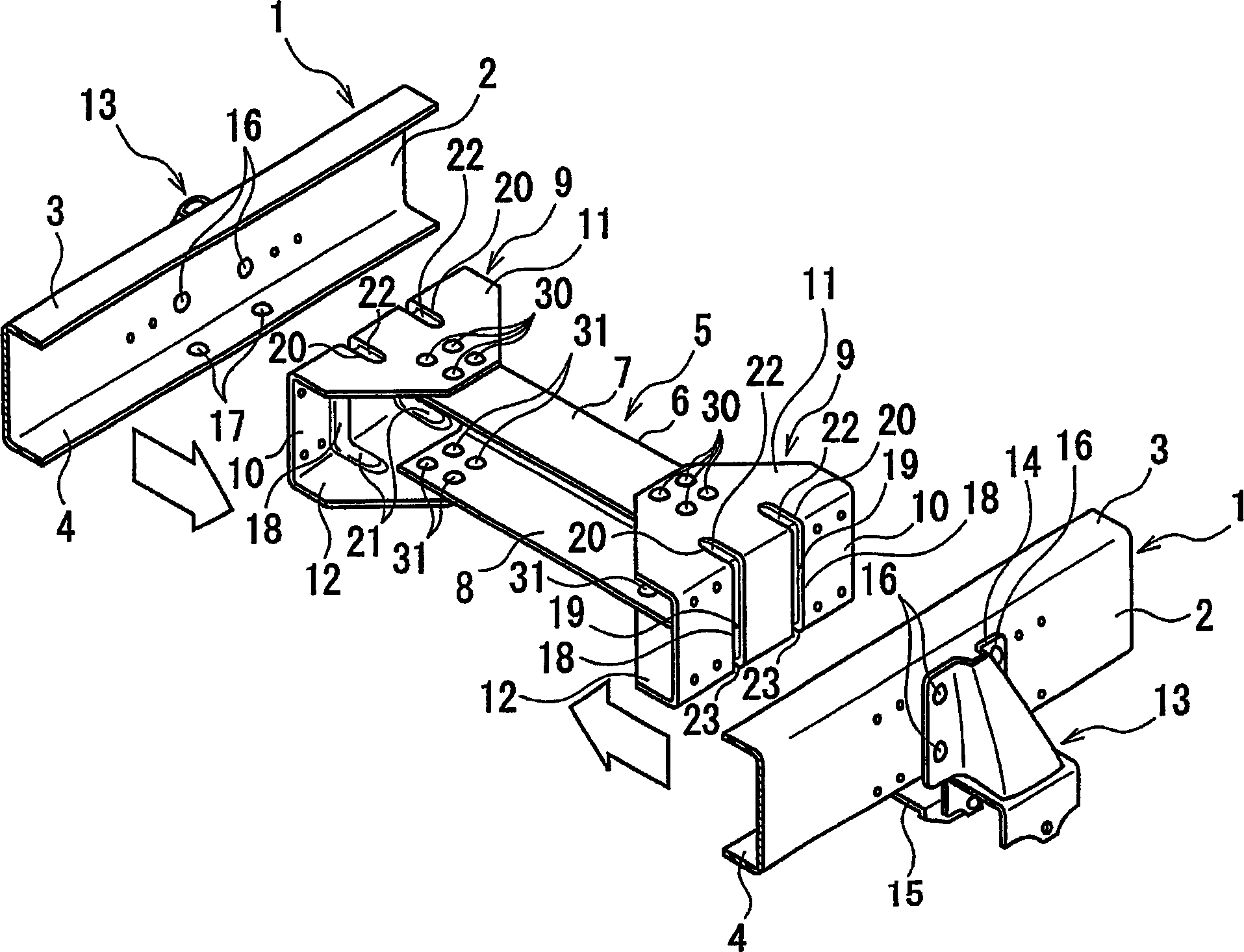

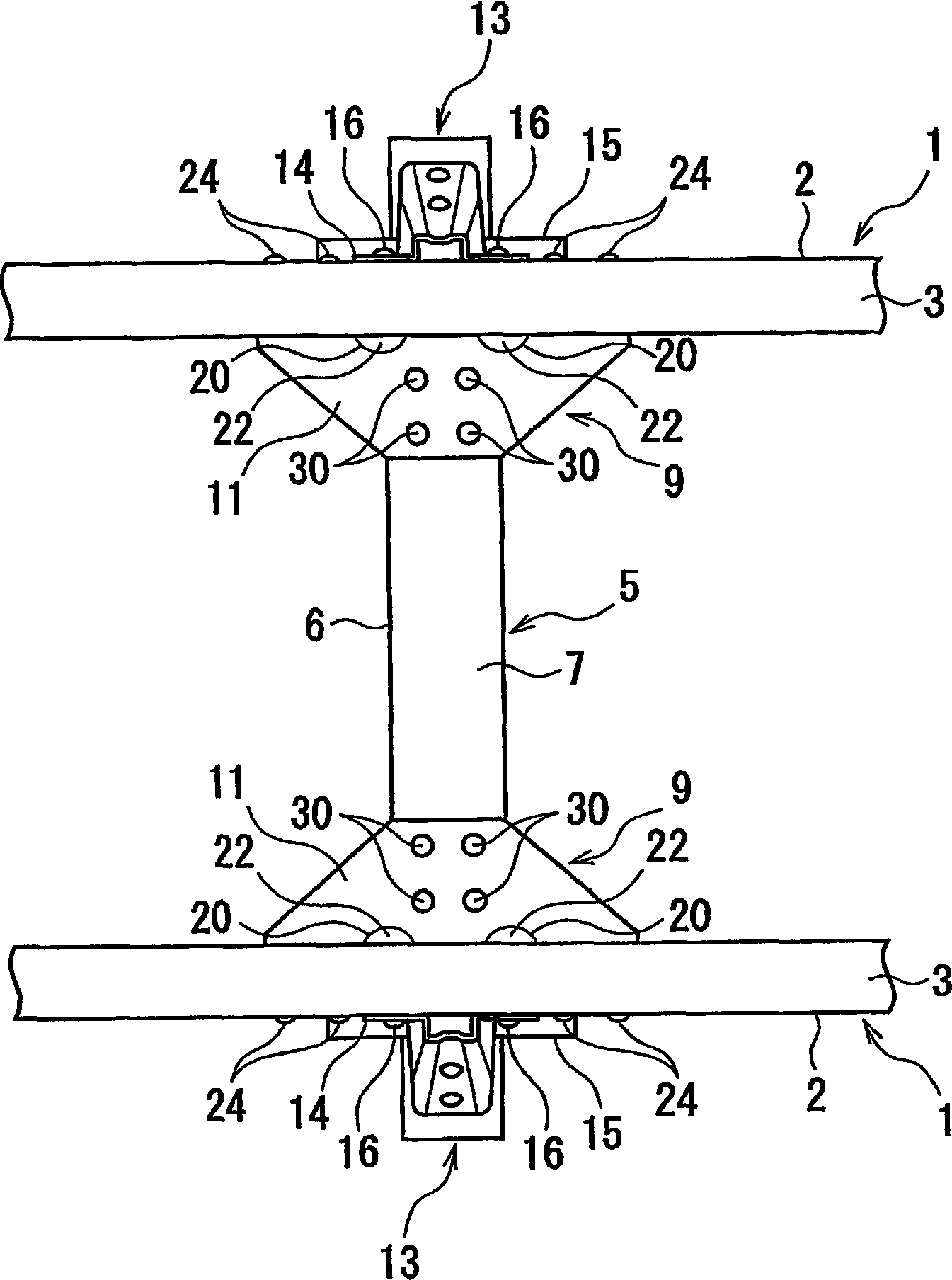

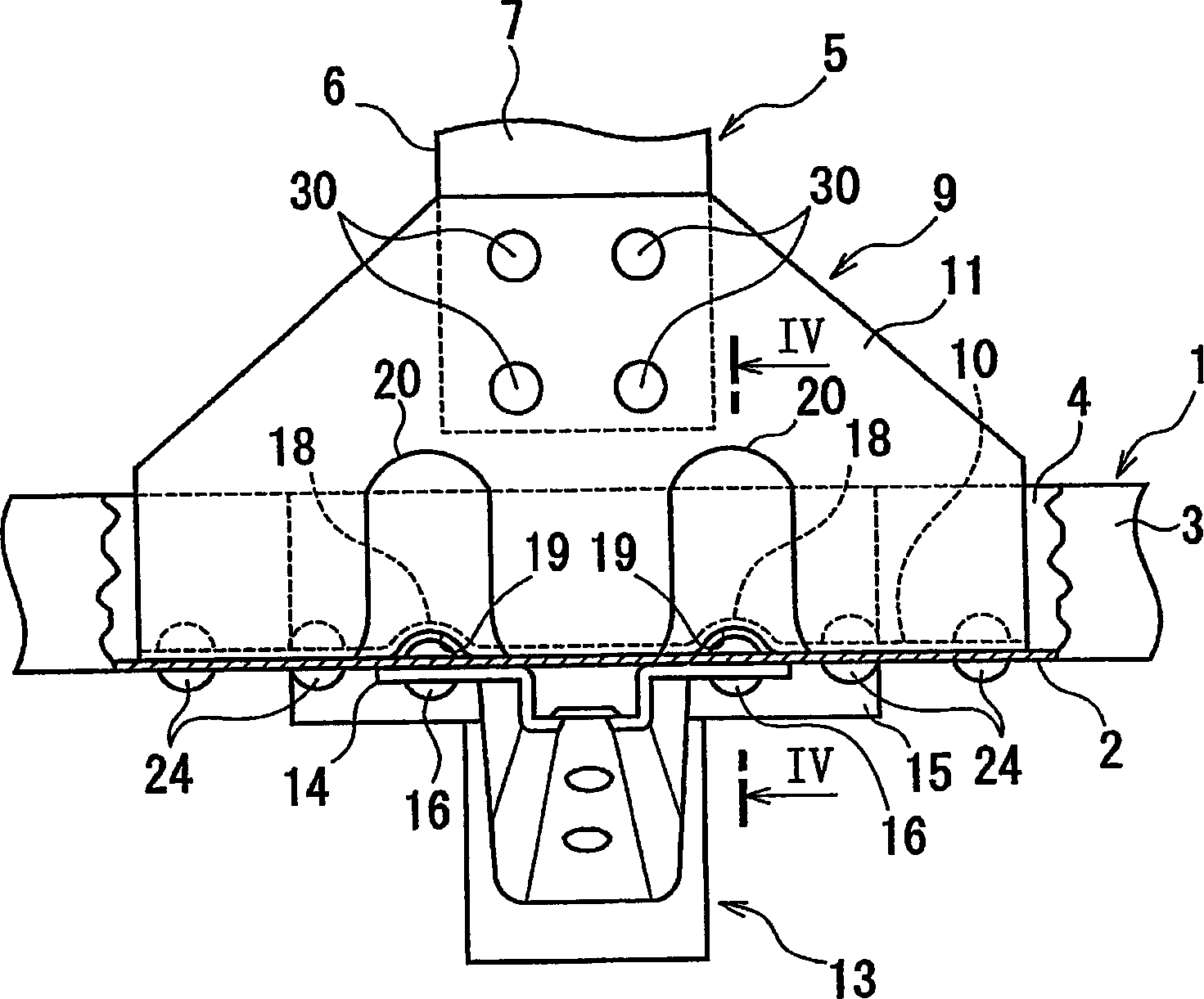

[0029] figure 1 is an exploded perspective view of the connection structure according to this embodiment. figure 2 yes figure 1 A top view of the assembled state. image 3 yes figure 2 An enlarged view of the main part with the upper horizontal plate of the side member shown partially broken. Figure 4 is along image 3 Sectional view taken along line IV-IV. Note that in the following description, the longitudinal direction refers to the front-rear direction of the vehicle body, and the lateral direction refers to the left-right direction seen when facing the front side of the vehicle body.

[0030] Such as figure 1 and 2 As shown, a pair of left and right side members 1 and a cross member 5 are provided as frame members at the lower portion of the vehicle body having a frame. The side members 1 extend in the longitudinal direction of the vehicle bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com