Method and installation for the production of an aluminum sheet with a textured surface

A technology of anilox and anilox rolls is applied in the driving device, manufacturing tool, metal rolling and other directions of metal rolling mills, which can solve the problems of high production cost and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

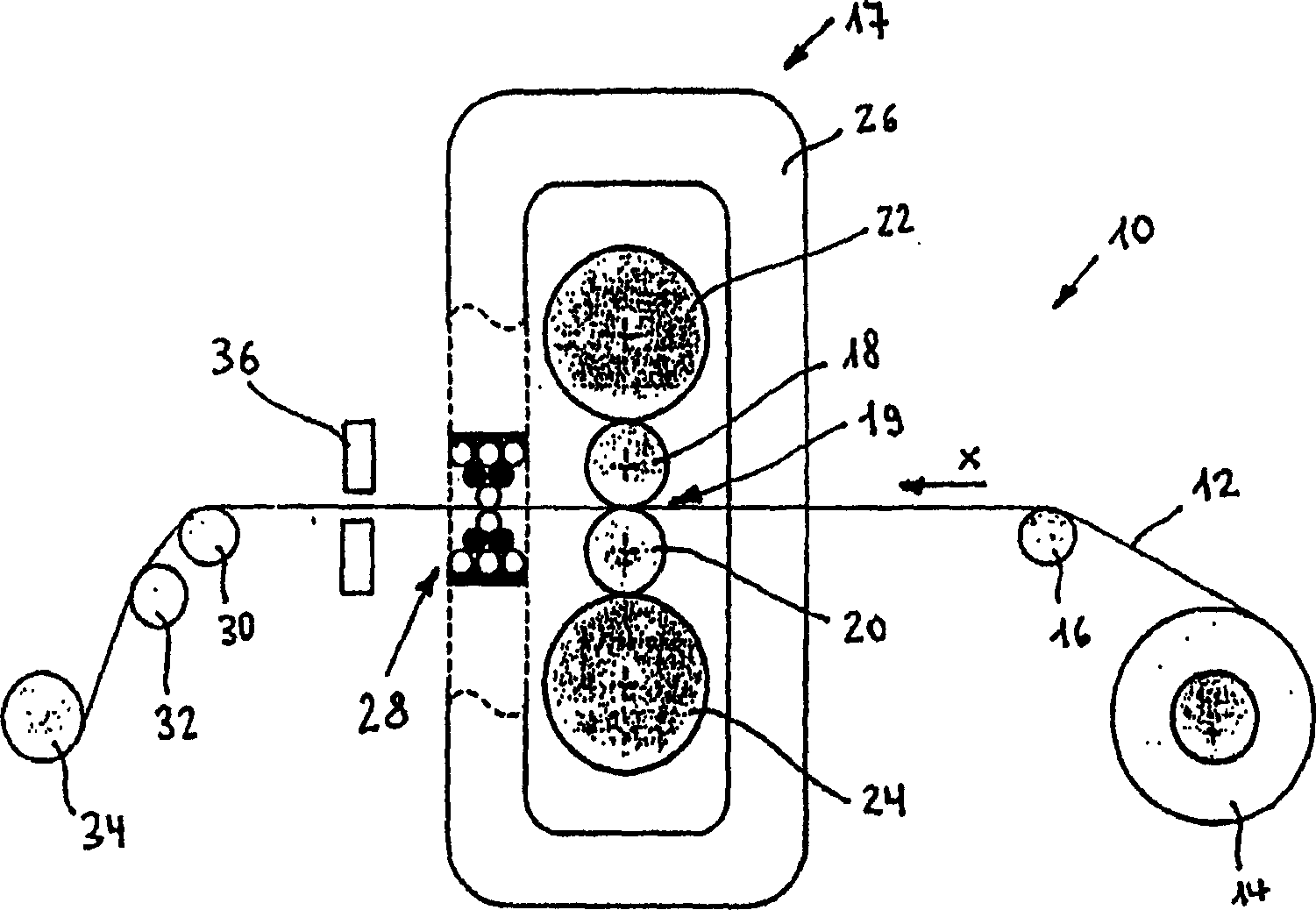

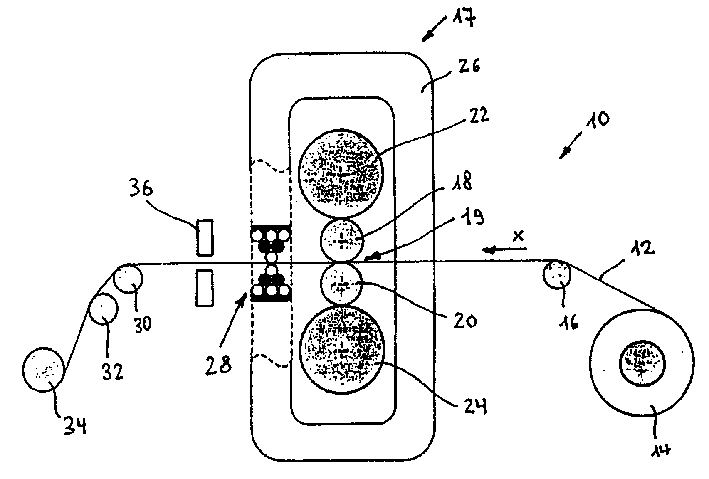

[0023] according to figure 1 The apparatus for producing aluminum strip with a textured surface comprises a cold rolling mill 17 having two work rolls 18, 20 forming a nip 19 and two backup rolls 22, 24 supporting the work rolls. The work rolls 18, 20 and backup rolls 22, 24 are mounted in a mill stand 26 in a known manner.

[0024] Also mounted in stand 26 is an anilox stand 28 which is smaller than cold rolling mill 17 .

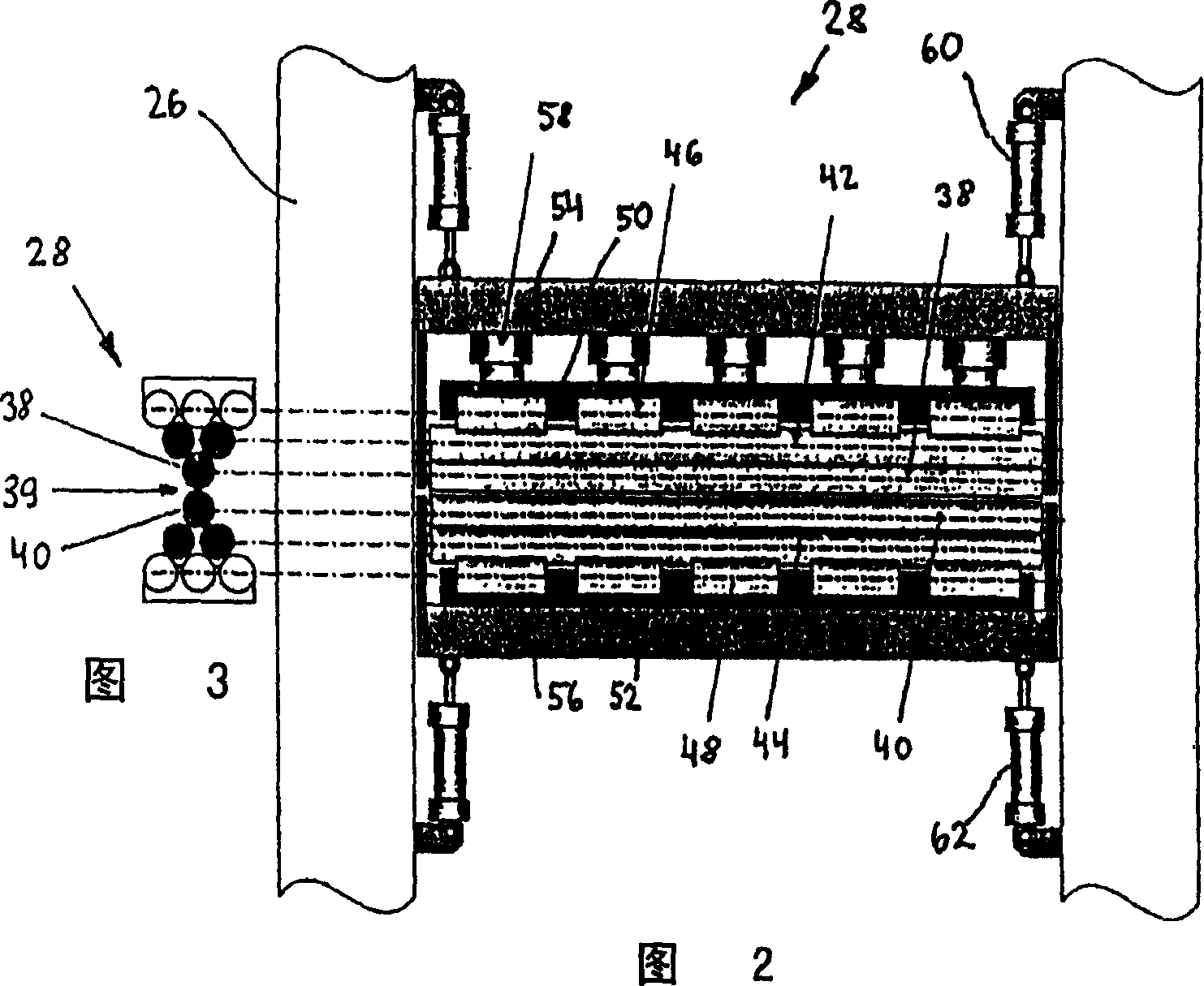

[0025] As shown in FIGS. 2 and 3 , the anilox roll stand 28 has two anilox rolls 38 , 40 which define a nip 39 and are supported by a pair of intermediate rolls 42 , 44 . Each pair of intermediate rolls 42,44 is supported by three sets of five backup rolls 46,48 each. The back-up rolls 46, 48 are mounted on beams 50, 52 which extend over the entire roll width. The upper beam 50 is supported by means of hydraulic pistons 58 by the upper part 54 of the roll stand, and the lower beam 52 rests directly on the lower part 56 of the roll stand. The two parts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com