Shuttering member

A formwork component and component technology, applied in the field of formwork components, can solve the problems of inconvenient production, high cost, and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

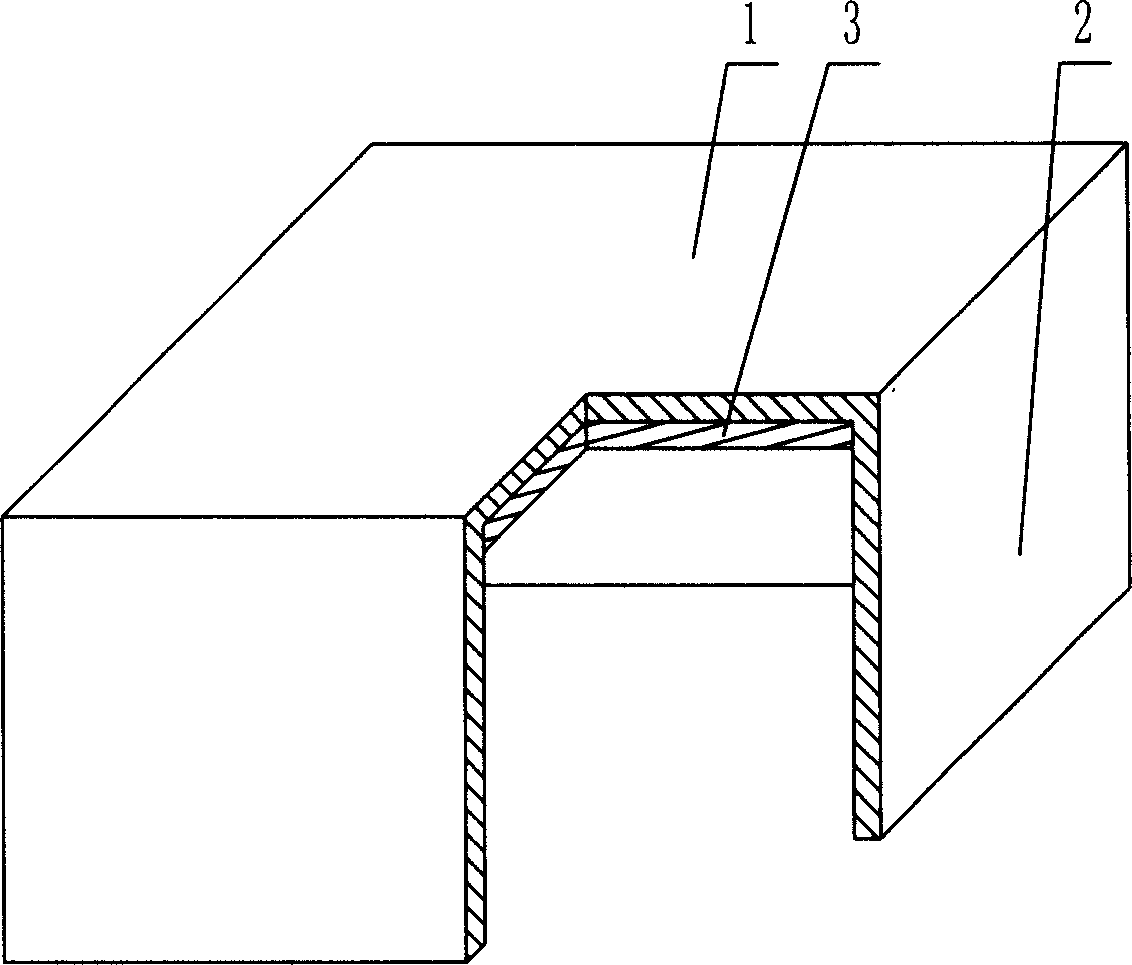

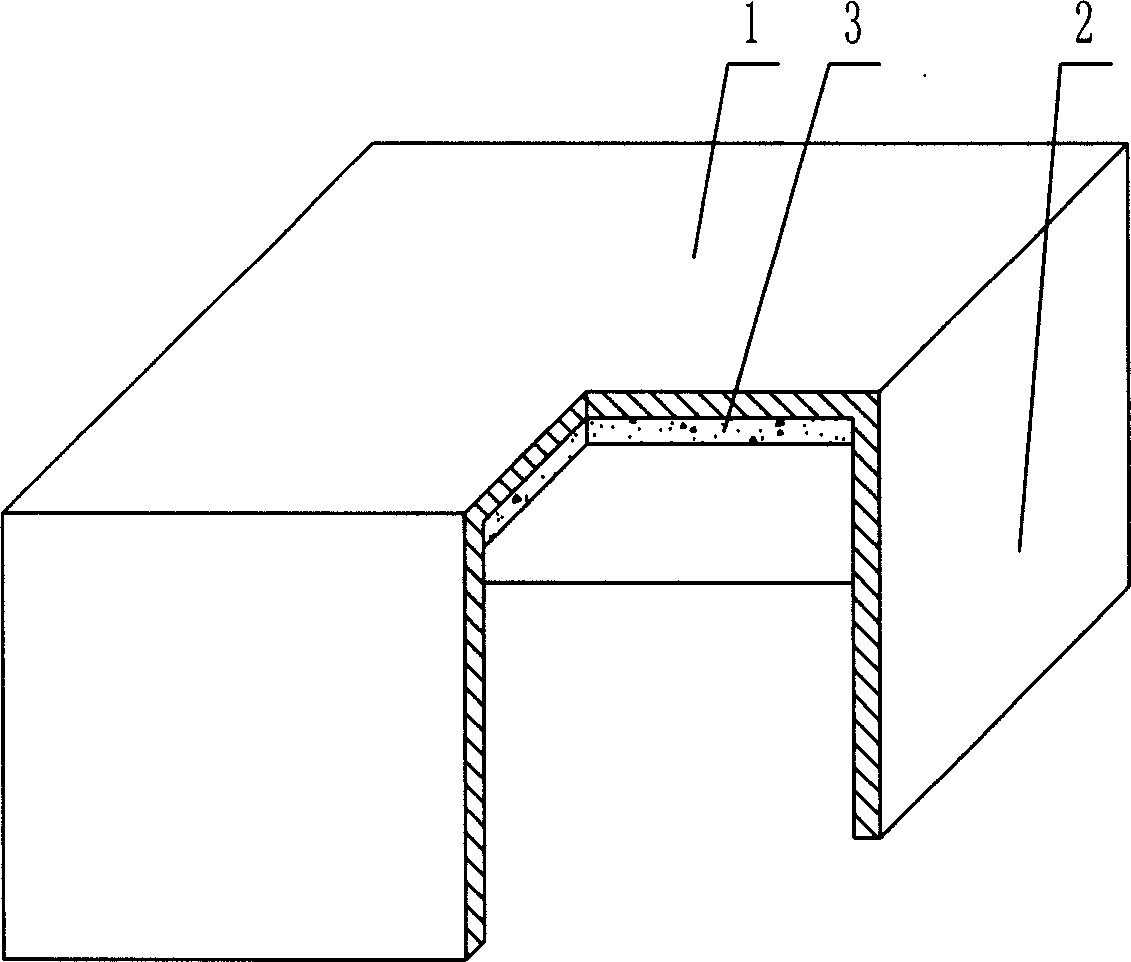

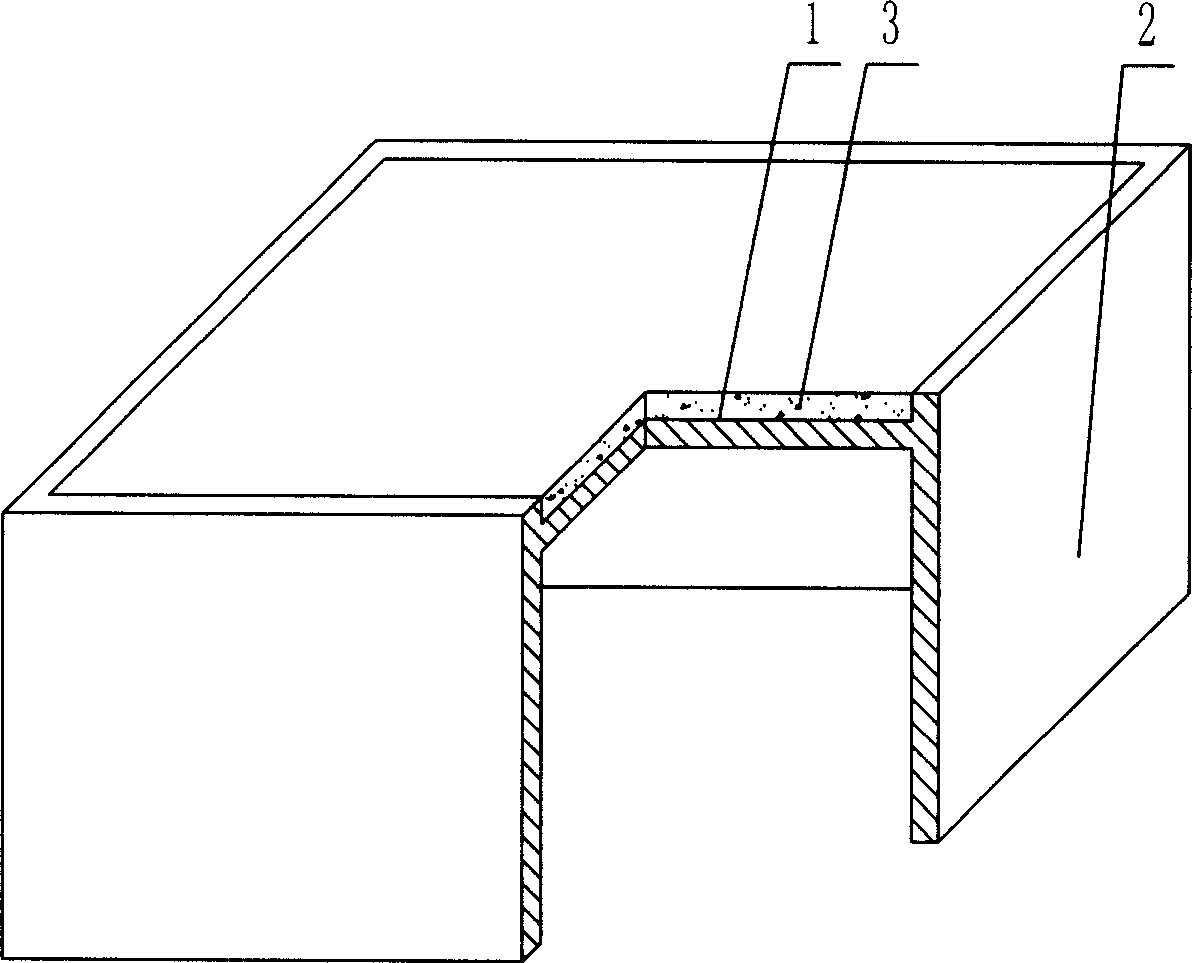

[0045] As shown in the accompanying drawings, the present invention includes an upper plate 1 and surrounding side walls 2, and the upper plate 1 and the surrounding side walls 2 form an open pot-shaped member, which is characterized in that the upper plate 1 and the surrounding side walls 2 At least one base layer is laminated with at least one laminated layer 3, and the laminated layer 3 is laminated with the base layer as a whole. figure 1 It is a structural schematic diagram of Embodiment 1 of the present invention. In each drawing, 1 is the upper plate, 2 is the surrounding side wall, and 3 is the laminated layer. In the following drawings, those with the same number have the same description. Such as figure 1 As shown, the upper plate 1 and the surrounding side walls 2 form an open basin-shaped member, and the base layer of the upper plate 1 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com